- BIS Scheme X is a voluntary certification scheme under the Bureau of Indian Standards (BIS).

- Ideal for non-notified products like most packing and packaging machinery.

- Ensures quality, safety, and performance compliance as per Indian Standards.

- Allows use of the ISI mark even before the product is covered under mandatory BIS notifications.

- Helps qualify for government and export tenders.

- Applicable for both Indian & Foreign Manufacturer

Introduction

Manufacturing and packaging have become a speedy environment where filling machines, closing machines, sealing machines, labeling machines, packaging machines, and wrapping machines are vital for the industry-from food and beverages through pharmaceuticals, and cosmetics. With the BIS Scheme X for Packing Machinery aid of these machines, products are made to conform to safety and quality standards. At the same time, machinery helps guarantee efficiency.

Bureau of Indian Standards(BIS) has various certification schemes for categories of machinery applicable to the manufacturing and packing processes, etc. All types of these machines are under BIS Scheme X certification; this blog describes the kind of machinery that falls under BIS Scheme X, their components, and what it means for manufacturers in India to get BIS certification.

What Is BIS Scheme X Certification?

Under the BIS Scheme X, there are guidelines concerning certification requirements of machines, equipment, and components utilized across various manufacturing and packaging processes. Such a certificate signifies that the equipment is in line safe, performance, and quality standards set by the Bureau of Indian Standards (BIS). End-users in packaging and labeling can thus have quality assurance in BIS Scheme X certification adoption.

BIS Scheme X lays down requirements for certification of machinery, equipment, and components based on diverse manufacturing and packaging processes. This type of certificate ensures that the machinery is inline with safe, as well as at the quality standards set by the Bureau of Indian Standards (BIS). Hence, the Certification for Packing Machinery end-users can have a quality assurance in having BIS Scheme X certification.

BIS Scheme X certification relates to many kinds of machinery, including filling machines, sealing machines, wrapping machines, and their subassemblies or assemblies. It specifies that the machinery conforms to technical requirements and quality standards under the relevant BIS standards.

Types of Machinery Under the BIS Scheme X for Packing Machinery

India has different industries requiring key machines to be BIS Scheme X-certified.

1. Filling Machinery:

Among factories, there are food, drink, and pharmaceutical industry filling machines. Filling machines help fill bottles, jars, or other containers with a specific amount of liquid or semi-liquid products.

Different types of filling machinery include:

- Liquid Filling Machines: Beverages, oils, pharmaceuticals, and other liquids.

- Paste Filling Machines: For thicker products such as sauces, creams, and gels.

- Powder Filing Machines: For spices, powdered milk, and flour.

- Granular Filling Machines: For products such as rice, sugar, and seeds.

The filling machine must meet tight quality standards with regards to measuring, waste, and compositional quality. The BIS Scheme X certification is a certification that these machines meet with safety and quality standards for uptake in the industry.

2. Closing Machines

Closing machines perform sealing containers after a container has been filled. This is the use of caps or other closures to seal a bottle or jar after it has been filled. They can therefore be said to be tamper-proof because of the tight seal formed. Additionally, some different types of closing machinery are:

- Cap Sealing Machines: Used in the application of caps unto bottles and jars.

- Corking Machines: Sealing entire bottles with cork (mostly used in the wine industry)

- Induction Sealers: Seal edges of plastic containers using an induction heat process.

BIS certification for closing machinery would make sure these machines were able to be used in different closure types with seal reliability performance and to safety standards.

3. Sealing Machinery

Sealing machinery is designed in such a way that it seals end-user packages so that the products remain intact inside during storage and transport. It is more so used in the food and beverage sectors, pharmaceuticals, and cosmetics.

Common sealing machinery includes:

- Heat Sealers: Heat sealers are used for flexible packaging materials including plastic, aluminum foil, and many others.

- Vacuum Sealing Machines: This machine is used for the vacuum sealing process in packaging products, with the aim of preserving freshness.

- Band Sealers: For sealing bags and pouches in packaging lines.

These have to be precisely done and maintained consecutively to uphold the integrity of the product inside. The BIS certification for sealing machinery makes sure that the equipment meets the quality and safety standards required for various industries.

Assemblies, Subassemblies, and Components Under BIS Scheme X Certification

The equipment for filling, closing, sealing, labelling, packing, and wrapping consists of various assemblies, subassemblies, and accessories, all of which must meet the same criteria for ensuring proper and safe functioning of the final assembly. Generally, assemblies and components included in the BIS Scheme-X certification are:

- Conveyor Systems: Used for the transportation of products from one manufacturing stage to another in packaging.

- Pneumatic and Hydraulic Systems: Generally used in the movement and operational control of machines.

- Electrical Control Panels: To control the function of the machines.

- Sensors and Actuators: Responsible for detecting the products and controlling their flow through the machine.

Each one of the components defined has to be certified under the BIS Scheme-X to ensure that the entire machine meets the required standards of safety and quality.

Why Is BIS Scheme X Certification Important?

1. Ensures That The Indian Standards Are Followed

Certification under the BIS Scheme X confirms compliance for machinery under safety, performance, and quality standards set forth in India. The Scheme assists manufacturers with regulatory conformance to ensure that the machine is fit for use in India.

2. Promotes Quality and Safety

Certification by BIS, which guarantees the machinery is subject to control of quality, renders better quality and safety of the packaged products. This process is vital in the food and pharmaceutical sectors to avert contamination and maintain product integrity.

3. Enhances Consumer Confidence

When a manufacturer uses machinery that is BIS certified, it tells consumers that the product was manufactured on machinery that meets high-quality and safety standards. This enhances trust in the brand and confidence in the product.

4. Ensures Entry into the Market

Most of the time, BIS certification will be a condition to access the market in India. With such certification in hand, the manufacturers can be sure that their products are adhering to local standards and are free to market without any legal trouble.

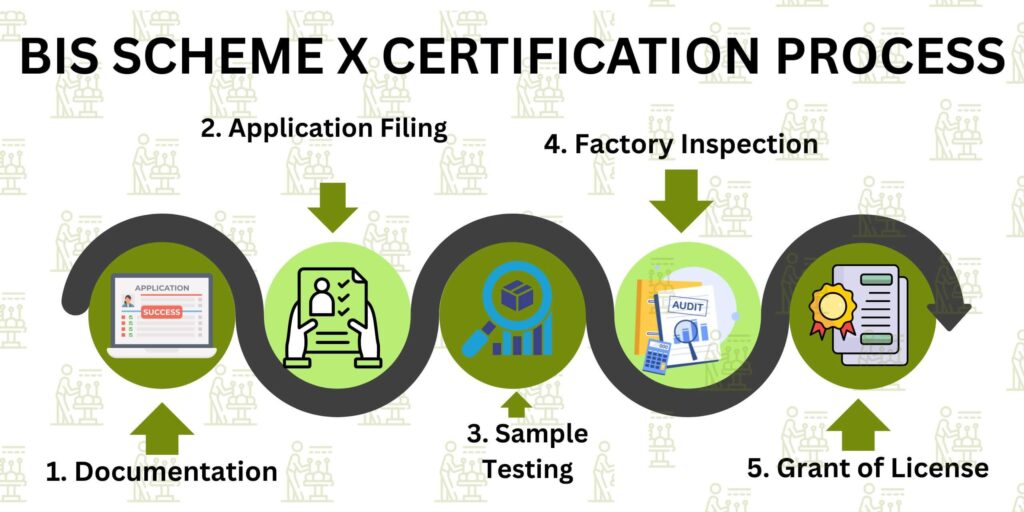

Process for BIS Scheme X for Packaging Machinery

Some important terms of obtaining BIS Scheme X certification for a machine are:

Step 1: Consultation and Requirement Analysis

The first step is to understand your machinery and whether it falls under the BIS Scheme X. Our experts at Diligence Certification will:

- Review the type of machinery or components you manufacture (e.g., filling, sealing, wrapping machines, etc.).

- Identify the applicable Indian Standards (IS codes).

85 - Explain the specific requirements your product needs to fulfill.

Step 2: Document Preparation

Once we know what standards apply, the next step is to get your documents ready. This includes:

- Product specifications and technical drawings

- Test reports (if available)

- Manufacturing process details

- Quality control documents

- Factory layout and machinery details

We assist you in compiling and organizing all the necessary paperwork so that your application is complete and compliant.

Step 3: Factory Inspection by BIS Officials

After applying, BIS officials will schedule a factory inspection. Here’s what happens:

- A BIS team visits your manufacturing unit.

- They verify the machinery, process controls, safety protocols, and overall compliance.

- Product samples may be collected for further testing at BIS-approved laboratories.

Step 4: Product Testing & Evaluation

Samples taken from your facility are tested at BIS-approved labs to ensure the machinery or its components meet Indian standards.

- The machinery is checked for quality, performance, and safety.

- If the product passes the tests, the results are submitted to BIS for review.

Step 5: Grant of BIS Certification

Once your documents are approved, the factory inspection is cleared, and test results meet BIS standards, you will receive the BIS Certificate under Scheme X.

- You’re now authorized to use the ISI Mark on your machines.

- Your machinery is officially recognized as safe and compliant for Indian markets.

Why Diligence Certification?

When getting BIS Scheme X certification for your machinery, the certification body you choose can make all the difference. Diligence Certification helps you with consulting services through the intricacies of the BIS certification. Here is why working with Diligence Certification is your best option:

1. You Have Experts in BIS Certification Process

At Diligence Certification, we possess vast knowledge and experience in handling the BIS certification process for various machinery, including those used for filling, closing, sealing, labeling, packing, and wrapping. Thus, you have the assurance that every member of our professional staff makes you know about the requirements of the certification and guides you to complete all steps for fulfilling all the regulatory standards.

2. Customized Consultation

Diligence Certification provides a customized consultation service tailored to your specific requirements. Your project will benefit from our personalized assistance to help you get your machinery and equipment exactly to the technical specifications for BIS Scheme X certification.

3. Simplification

At Diligence Certification, we simplify the whole process for you. We take care of everything, from preparing and submitting documents to following up with the BIS authorities; all you need to do is run your business.

4. Timely Certification

If time is money, then timely certification becomes a necessity, especially for operations that depend on efficiency and smooth running. Diligence Certification prides itself on delivering during the promised time.

5. Support and Guidance after Certification

The end of certification marks only the beginning of our help. From Diligence, you will be provided with continuous support even after you get BIS certification. Maintenance, recertification, and changes in BIS regulations that can affect your machine are the topics we will advise on.

7. Trusted by Leading Brands

For their BIS certification needs, leading brands across India trust Diligence Certification. Renowned for quality service and assisting businesses with complying with industry standards, we have emerged as a preferred choice for many manufacturers.

Conclusion

BIS Scheme X Certification is required from manufacturers in India for their machines used in filling, closing, sealing, labelling, packing or wrapping bottles under Indian standards ensuring safety and quality of products.

Partnering with Diligence Certification for BIS Scheme X certification ensures that you work with the true professionals who understand everything about the nuances of the certification process in the best way. Certified machinery is beneficial for a manufacturer operating his production facilities, enhancing the quality of his products, and building consumer trust. Diligence Certification will assist you in understanding and following the BIS certification process easily and ensuring that your machinery gets successfully certified.

For expert assistance and consultation for BIS Scheme X certification, contact Diligence Certification to assure that your machinery complies with the best standards in the industry.

Frequently Asked Questions (FAQs)

What is BIS Scheme X?

A voluntary BIS certification for products not yet under mandatory regulation.

Is BIS certification mandatory for packing machinery?

No, it’s voluntary under Scheme X (as of 2025).

What types of machines can apply?

Filling, sealing, pouch packing, labeling, and blister packaging machines.

Who can apply?

Indian and foreign manufacturers with proper factory setup and documents.

How long does it take?

Usually 4–8 weeks depending on testing and inspection.

Is the ISI mark included?

Yes, certified machines can carry the ISI mark under Scheme X.

What’s the validity of the license?

Typically 1–2 years, with renewal required.

What documents are needed for BIS Scheme X?

Factory license, product specs, test reports, and quality control details.

Can BIS Scheme X help with exports?

Yes, it improves product acceptability in both domestic and international markets.

What are the benefits of BIS Scheme X for manufacturers?

It builds customer trust, ensures quality compliance, increases market competitiveness, and helps manufacturers access government tenders and export opportunities.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration