- Mandatory Safety Compliance Compliance BIS Certification Leather safety boots and shoes for heavy metal industries under IS 1989( Part 2) 1986 ensures leather safety thrills and shoes meet strict quality and safety standards needed for heavy essence diligence.

- Protection Against Industrial Hazards Certified thrills give resistance against impact, perforations, and molten essence splashes, securing workers from common plant injuries.

- Durable and Long- Lasting Leather safety footwear is designed for high continuity, maintaining performance under harsh artificial conditions while offering comfort for dragged use.

- Quality Assurance through Testing BIS- certified thrills suffer rigorous testing for sole strength, leather quality, resistance to chemicals, and slip resistance to ensure maximum safety.

- Enhanced Workplace Safety and Compliance Using pukka footwear reduces plant accidents, promotes legal compliance, and enhances hand confidence and productivity.

Introduction

BIS Certification for Leather safety boots and shoes for Heavy Metal diligence under IS 1989( Part 2) 1986 plays a vital part in guarding workers in heavy essence diligence, where exposure to extreme hazards is a diurnal reality. Workers in these sectors face pitfalls similar to falling heavy objects, sharp tools, molten essence splashes, slippery shells, and electrical hazards. Wearing leather safety thrills and shoes certified under BIS ensures that the footwear meets strict safety and quality conditions defined in IS 1989( Part 2) 1986. This standard specifies the design, accoutrements , testing procedures, and performance criteria for artificial safety footwear, fastening on continuity, impact resistance, slip resistance, and overall protection. By clinging to these standards, manufacturers can give thrills that not only repel harsh working conditions but also offer comfort for long hours of use. For diligence, using BIS- pukka leather safety footwear is further than just a nonsupervisory demand; it is an investment in plant safety, accident forestallment, and legal compliance.

What is IS 1989 (Part.2): 1986 ?

IS 1989( Part 2) 1986 is an Indian Standard that specifies the conditions for leather safety thrills and shoes used in artificial operations, particularly in heavy diligence similar to metalworking, mining, and construction. Part 2 of this standard focuses on defensive footwear made of leather, detailing the design, accoutrements , testing styles, and performance criteria to insure safety and durability.The standard ensures that artificial footwear can cover workers from common hazards similar as impact, contraction, perforations, molten essence splashes, and slippery shells, while also furnishing comfort for dragged use. It’s a critical reference for manufacturers, suppliers, and safety controllers to maintain workplace safety standards.

Key Points:

- Compass of Protection Covers leather safety thrills and shoes designed for artificial workers exposed to mechanical and thermal hazards.

- Material standards Specifies the quality of leather, sole accoutrements , and fresh mounts like sword or compound toe caps to insure continuity and resistance.

- Design Conditions Ensures proper befitting, ankle support, slip resistance, and shock immersion for all artificial footwear.

- Testing & Compliance Details tests for impact resistance, contraction resistance, slip resistance, perforation resistance, and electrical sequestration, icing pukka footwear meets safety marks.

- Worker Safety and Legal Compliance Using footwear that meets IS 1989( Part 2) 1986 reduces workplace accidents, complies with Indian occupational safety regulations, and enhances overall artificial safety culture.

Why is BIS Certification Mandatory

BIS (Bureau of Indian Standards) Certification is obligatory for Leather safety boots and shoes used in heavy diligence because it ensures that the footwear meets strict safety, quality, and performance standards defined under IS 1989( Part 2) 1986. Artificial workers are exposed to multiple hazards similar as falling heavy objects, molten essence splashes, sharp tools, and slippery shells. Without pukka safety footwear, the threat of serious bottom injuries increases significantly.

Key Points:

- Legal Demand BIS Certification is obligatory for artificial safety footwear in India to misbehave with occupational health and safety regulations.

- Assures Safety Certified thrills are tested for impact resistance, contraction, slip resistance, perforation resistance, and thermal hazards, furnishing maximum protection to workers.

- Quality Guarantee Ensures that the leather, soles, and design of the footwear meet high standards of continuity, comfort, and performance.

- Reduces Workplace Accidents Helps in minimizing bottom injuries, guarding workers in heavy essence diligence and other dangerous sectors.

- Builds Trust and Credibility Employers and diligence using BIS- certified footwear demonstrate commitment to worker safety and quality compliance.

- Request Advantage for Manufacturers BIS Certification improves brand credibility and acceptance in artificial requests, as buyers prefer certified and safe products.

Importance and Benefits of BIS Certification

| Importance of BIS Certification | Benefits of BIS Certification |

| Ensures compliance with Indian safety standards( IS 1989 Part 2 1986). | Provides guaranteed safety against artificial hazards like impact, perforation, and molten essence. |

| fairly needed for artificial safety footwear in heavy essence and other dangerous diligence. | Enhances worker confidence and protection, reducing plant accidents. |

| Confirms that the material quality and design meet rigorous safety specifications. | Ensures durable and long- lasting footwear, saving relief costs over time. |

| Acts as a standard for manufacturers to maintain harmonious quality in product. | Builds brand credibility and requests trust for manufacturers and suppliers. |

| Promotes workplace safety culture by setting minimal safety standards. | Helps companies meet nonsupervisory and legal scores, avoiding forfeitures or penalties. |

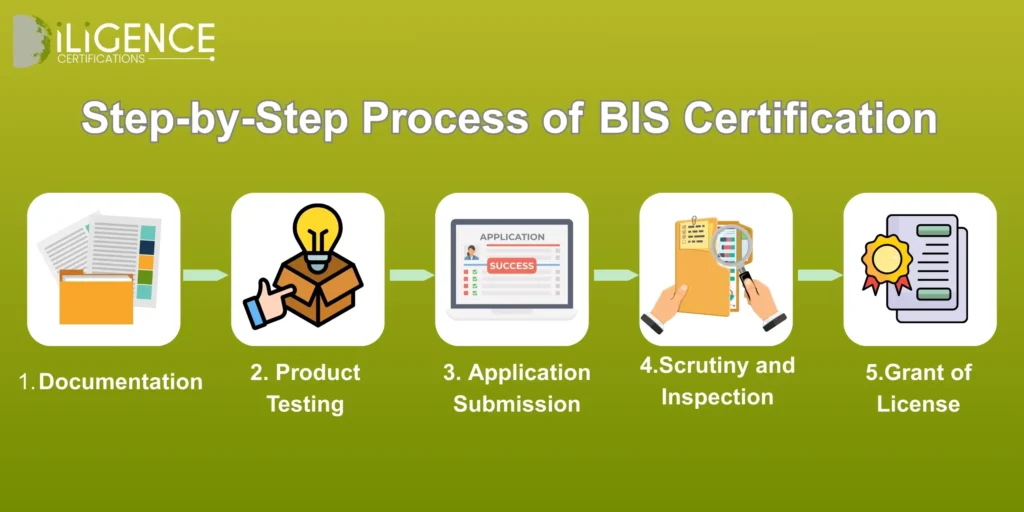

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Company Registration | Certificate of Incorporation / Business Registration proof |

| Manufacturing Unit Details | Factory address proof, layout plan, and list of manufacturing machinery |

| Product Information | Product specification and technical data sheet |

| Quality Control Documents | Quality control manual and in-house testing procedures |

| Test Reports | Product test report from a BIS-recognized laboratory |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- Expert BIS Guidance Helps manufacturers navigate the complete BIS Certification process for safety footwear with professional moxie.

- End- to- End Support Assists in attestation, testing, plant checkups, and final Certification blessing.

- Ensures Compliance Guarantees that leather safety thrills meet IS 1989( Part 2) 1986 safety and quality standards.

- Boosts Credibility Enhances brand trust, request acceptance, and client confidence with pukka products.

- Time & Cost Effective Streamlines processes to save time, reduce crimes, and avoid expensive detainments.

Conclusion

BIS Certification for Leather safety boots and shoes for Heavy Metal diligence under IS 1989( Part 2) 1986 is essential for icing worker safety, nonsupervisory compliance, and overall plant effectiveness in dangerous artificial surroundings. pukka leather safety footwear protects workers from mechanical, thermal, and chemical hazards while furnishing continuity and comfort for long working hours.Choosing Diligence Certifications for your BIS Certification needs ensures a smooth, dependable, and professional process, from attestation and testing to final blessing. By partnering with experts, manufacturers can guarantee high- quality, biddable safety thrills that meet IS 1989( Part 2) 1986 standards, strengthen their brand credibility, and contribute to a safer artificial pool.

Frequently asked questions

What is BIS certification for safety footwear?

It ensures leather safety boots meet Indian safety standards (IS 1989 Part 2: 1986) for industrial protection.

Is BIS certification mandatory for industrial boots?

Yes, for compliance with safety regulations in heavy metal and hazardous industries.

What hazards do BIS-certified boots protect against?

Impact, compression, puncture, molten metal, and slippery surfaces.

What is IS 1989 (Part 2): 1986?

An Indian standard specifying safety, design, and testing requirements for leather industrial footwear.

Who issues BIS certification?

The Bureau of Indian Standards (BIS), an official national standards body in India.

How long does BIS certification take?

Typically 4–8 weeks, depending on testing and documentation completion.

Can manufacturers sell non-BIS certified boots?

Not legally for industrial use; BIS certification is required for compliance.

What are the benefits of BIS-certified leather boots?

Safety assurance, durability, legal compliance, and increased market trust.

How does Diligence Certifications help?

They provide expert guidance, testing support, documentation assistance, and end-to-end certification services.

Are BIS-certified boots suitable for all heavy industries?

Yes, especially in metal, mining, construction, and chemical sectors requiring foot protection.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration