- Mandatory quality safe and dependable packaging of 50 kg cement bags in India as per BIS standards.

- IS 16709:2017 PP Woven Laminated Block specifies conditions for PP woven laminated fabric, block nethermost construction, and stopcock design.

- Covers performance tests for tensile strength, confluence strength, drop resistance, and humidity protection.

- Ensures continuity, leak forestallment, and protection of cement during storehouse, handling, and transportation.

- BIS mark confirms product quality, thickness, and compliance with Indian packaging norms.

Introduction

BIS certification for PP Woven Laminated Block Bottom Valve Sacks for 50 kg Cement, as per IS 16709:2017, ensures standardized quality and performance of cement packaging used in India. This instrument confirms that the sacks are strong, humidity- resistant, and suitable for safe storehouse, handling, and transportation of cement, while meeting the obligatory conditions set by the Bureau of Indian standards.

What is IS 16709:2017?

IS 16709:2017 is an Indian Standard issued by the Bureau of Indian standards( BIS) that lays down the specialized and quality conditions for PP woven laminated block bottom stopcock sacks specifically designed for packing 50 kg cement. The standard defines specifications for raw accoutrements, woven fabric construction, lamination quality, block bottom conformation, and stopcock design to ensure safe and effective cement packaging. It also prescribes rigorous performance tests similar to tensile strength, confluence strength, drop resistance, and humidity hedge parcels to help leakage, impurity, and material loss.

Key Points:

- IS 167092017 is an Indian Standard issued by the Bureau of Indian standards( BIS) for PP woven laminated block bottom stopcock sacks used for packing 50 kg cement.

- It specifies conditions for raw accoutrements , fabric construction, lamination, block bottom design, and stopcock conformation.

- The standard includes performance tests similar to tensile strength, confluence strength, drop test, and humidity resistance.

- Ensures protection of cement against leakage, humidity doorway, and damage during storehouse and transportation.

- BIS certification under this standard is obligatory in India to ensure quality, safety, and non supervisory compliance.

Why is BIS Certification Mandatory

BIS certification is obligatory to ensure that PP woven laminated block bottom stopcock sacks for 50 kg cement meet the quality and safety conditions of IS 167092017. It helps help humidity doorway, leakage, and bag failure during running and transportation. obligatory BIS compliance ensures invariant packaging norms, protects cement quality, reduces material loss, and safeguards consumer and assiduity interests across India.

Key Reasons:

- BIS certificationis obligatory to insure PP woven laminated block bottom stopcock sacks misbehave with IS 16709:2017 quality standards.

- It prevents humidity penetration, leakage, and damage to cement during storehouse and transportation.

- instrument ensures harmonious strength, continuity, and performance of cement packaging.

- obligatory compliance protects manufacturers, cement directors, and end druggies from unacceptable products.

- BIS marking helps meet legal conditions and builds trust in product quality across the Indian request.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures PP woven laminated block bottom stopcock sacks meet IS 16709:2017 quality and safety conditions. | Enhances continuity and strength of cement sacks. |

| Maintains invariant norms for cement packaging across India. | Reduces cement loss during stuffing, transport, and storehouse. |

| Prevents use of unacceptable or low- quality packaging accoutrements . | Improves manufacturer credibility and requests acceptance. |

| Protects cement from humidity, leakage, and handling damage. | Builds trust among cement directors, distributors, and consumers. |

| Ensures nonsupervisory compliance with guidelines of the Bureau of Indian standards( BIS). | Enables legal trade and force of certified cement packaging in India. |

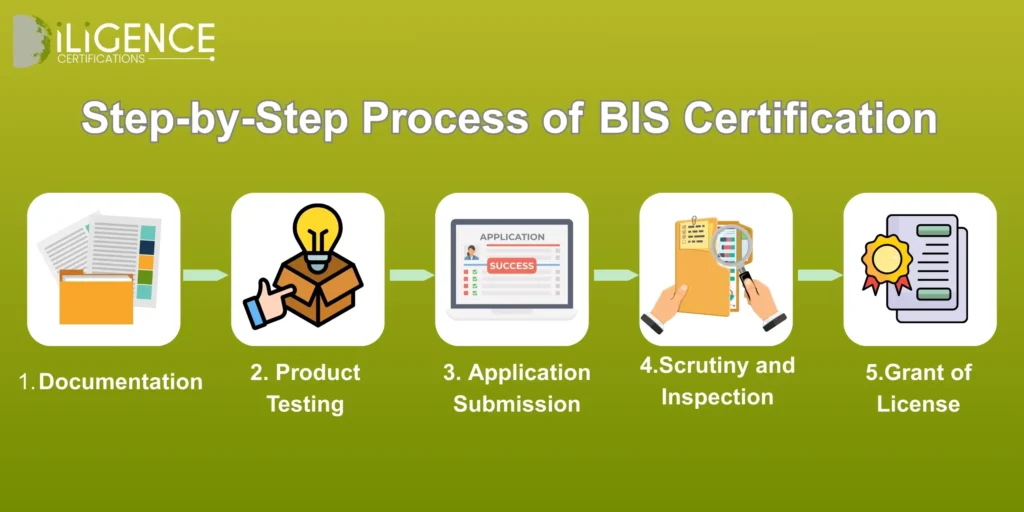

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications is a trusted compliance and instrument consultancy immolation end- to- end support for BIS instrument and other nonsupervisory blessings in India. With in- depth specialized moxie and a customer- concentrated approach, the company simplifies complex instrument procedures and ensures timely, hassle-free blessings. Diligence Certifications assists manufacturers at every stage — from attestation and product testing collaboration to operation form and liaison with authorities — helping businesses achieve compliance with applicable Indian norms efficiently. Their transparent process, educated professionals, and commitment to delicacy make industriousness instruments a dependable mate for achieving BIS instruments with confidence and ease.

Conclusion

BIS certification under IS 167092017 plays a vital part in icing the quality, safety, and trustability of PP woven laminated block bottom stopcock sacks used for 50 kg cement packaging. It helps maintain invariant norms, protects cement from humidity and damage, and ensures compliance with obligatory Indian regulations. clinging to this instrument not only safeguards product integrity but also builds trust across the force chain and supports sustainable, high- quality packaging practices in India.

Frequently Asked Questions (FAQs)

What's BIS certification under IS 16709:2017?

It's obligatory instrument icing quality and safety of PP woven laminated block bottom stopcock sacks for 50 kg cement.

Who issues IS 16709:2017?

The standard is issued by the Bureau of Indian standards (BIS).

Is BIS instrument mandatory for cement sacks?

Yes, BIS instrument is obligatory for manufacturers supplying these sacks in India.

What type of sacks are covered under this standard?

PP woven laminated block bottom stopcock ( cock) sacks used for packing 50 kg cement.

What are the crucial tests under IS 16709:2017?

Tensile strength, confluence strength, drop test, and humidity resistance tests.

Why is lamination important in these sacks?

Lamination prevents humidity doorway and protects cement quality.

Does BIS instrument help help cement leakage?

Yes, it ensures leak forestallment and strong confluence performance.

How long is the BIS license valid?

Generally, the BIS license is valid for 2 times.

Can uncertified cement sacks be vended in India?

No, dealing uncertified sacks is n't permitted under obligatory BIS morals.

What does the BIS mark indicate on cement sacks?

It indicates product quality, thickness, and compliance with Indian packaging norms.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration