- BIS certification to ensure quality, safety, and trustability of asbestos cement pressure pipes and joints in India.

- IS 15922003 specifies conditions for raw accoutrements , manufacturing process, and workmanship.

- Covers dimensional delicacy, pressure standing, and common performance for water force and sewage operations.

- Includes testing for hydrostatic pressure, crushing strength, and leakage resistance.

- BIS mark assures continuity, structural integrity, and compliance with Indian norms.

Introduction

BIS certification for Asbestos Cement Pressure Pipes and Joints as per IS 1592:2003 is an obligatory compliance demand in India for manufacturers supplying these products for public and artificial structure. The instrument is governed by the Bureau of Indian standards and aims to insure harmonious quality, safety, and performance of asbestos cement pressure pipes and joints used in water force, irrigation, and sewage networks.

IS 1592:2003 lays down detailed specifications covering raw material selection, manufacturing processes, dimensional forbearance, and workmanship to achieve dependable pressure- bearing capacity. The standard also prescribes rigorous testing conditions, including hydrostatic pressure tests, crushing strength tests, and leakage checks, to corroborate the mechanical strength and service felicity of the products. By complying with the BIS instrument, manufacturers demonstrate adherence to Indian quality morals, while buyers and design authorities gain assurance of continuity, structural integrity, and long service life. The BIS Standard Mark on asbestos cement pressure pipes and joints signifies conformity to IS 1592:2003 and supports safe, effective, and sustainable structure development across India.

What is IS 1592:2003?

IS 1592:2003 is an Indian Standard issued by the Bureau of Indian standards that specifies the conditions for asbestos cement pressure pipes and joints used substantially in water force, irrigation, and sewage systems. This standard defines guidelines for raw accoutrements , manufacturing, confines, pressure classes, and workmanship to ensure pipes and joints can safely repel internal pressure. It also prescribes obligatory tests similar to hydrostatic pressure, crushing strength, and leakage tests to corroborate performance and continuity. Compliance with IS 1592:2003 ensures product quality, trustability, and felicity for long- term structure use in India.

Key Points:

- IS 1592:2003 is an Indian Standard issued by the Bureau of Indian norms for asbestos cement pressure pipes and joints.

- It specifies conditions for raw accoutrements , manufacturing, and workmanship.

- Defines confines, pressure classes, and forbearance for pipes and joints.

- Prescribes tests similar to hydrostatic pressure, crushing strength, and leakage tests.

- Ensures continuity, safety, and felicity for water force, irrigation, and sewage systems.

Why is BIS Certification Mandatory

BIS certification is obligatory to ensure that asbestos cement pressure pipes and joints conform to the quality, safety, and performance conditions of IS 1592:2003. It protects public health and structure by icing products used in water force and sewage systems are durable, leak- evidence, and able to oppose needed pressure. The obligatory instrument, executed by the Bureau of Indian standards, also prevents the use of unacceptable accoutrements , promotes invariant manufacturing practices, and builds trust among government bodies, contractors, and consumers.

Key Reasons:

- Ensures asbestos cement pressure pipes and joints misbehave with IS 1592:2003 quality standards.

- Protects public safety by precluding leakage, failure, and structural blights.

- Verifies product performance through obligatory strength and pressure testing.

- Prevents the trade and use of unacceptable ornon-compliant products in India.

- Builds trust among government authorities, contractors, and consumers under the Bureau of Indian standards frame.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures strict compliance with IS 1592:2003 specialized and quality conditions. | Assures long service life and continuity of pressure pipes and joints. |

| Confirms pipes and joints can safely repel specified internal pressure. | Enhances trustability of water force, irrigation, and sewage systems. |

| authorizations formalized manufacturing and quality control processes. | Builds confidence among government departments, contractors, and buyers. |

| Reduces threat of channel failure, leakage, and structure damage. | Prevents use of unacceptable andnon-certified products in systems. |

| executed by the Bureau of Indian standards to regulate product quality nationwide. | Improves request acceptance and eligibility for public structure tenders |

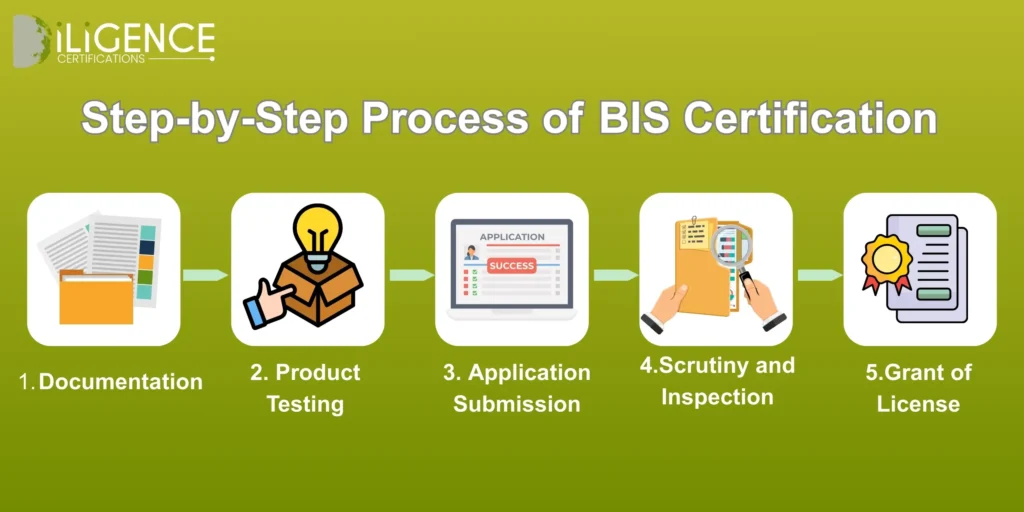

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications is a trusted compliance and instrument consultancy that helps manufacturers and importers achieve BIS certification easily and efficiently. With in- depth knowledge of Indian norms and nonsupervisory procedures, the platoon provides end- to- end support — from attestation and product testing to liaison with authorities and license blessing. By fastening on delicacy, translucency, and timely prosecution, Diligence Certifications minimizes detainments, reduces compliance pitfalls, and ensures a hassle-free instrument experience, allowing guests to concentrate on their core business while meeting all statutory conditions.

Conclusion

BIS certification for asbestos cement pressure pipes and joints as per IS 15922003 plays a pivotal part in icing quality, safety, and performance in critical water force and sewage structure. By complying with the norms set by the Bureau of Indian standards, manufacturers deliver durable, pressure- resistant, and dependable products, while druggies gain assurance of long service life and nonsupervisory compliance. Overall, BIS instrument supports sustainable structure development and protects public interest across India.

Frequently Asked Questions (FAQs)

What's IS 1592:2003?

It's an Indian Standard specifying quality and performance conditions for asbestos cement pressure pipes and joints.

Is BIS certification obligatory for these pipes?

Yes, BIS certification is obligatory for manufacturing and dealing these pipes in India.

Who issues BIS certification?

certification is issued by the Bureau of Indian standards.

Which operations are covered under IS 1592:2003?

Water force, irrigation, and sewage systems.

What tests are needed for BIS certification?

Hydrostatic pressure, crushing strength, and leakage tests.

Who can apply for BIS certification?

Manufacturers located in India or foreign manufacturers with an sanctioned Indian representative.

How long does BIS instrument take?

generally 20 – 30 days, including product testing.

What's the validity of BIScertification?

Generally valid for 2 times.

Can uncertified pipes be vended in India?

No, dealing non-BIS-certified products is banned.

Why is the BIS mark important?

It assures quality, safety, continuity, and compliance with Indian norms.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration