- Ensures compliance with IS 916 standard: IS Certification for Square Tins ensures that square tins conform to quality, safety, and performance standards as stipulated in IS 916. This ensures that these tins are adequate for packaging and storage purposes.

- Specifies Material Quality Requirements:It also defines the kind and quality of tinplate steel used, with the latter having sufficient strength, durability, and resistance to corrosion for long-lasting use.

- Ensures proper dimensions and construction:IS 916 offers accurate dimensions, thickness, and construction requirements for square tins, which aids in their compatibility and uniformity as used in industry and commerce.

- Guarantees Safety for Storage and Transportation: BIS Certification for Square Tins for the square tins ensures that they are leak-proof, sturdy, and safe for storage of products like oils, chemicals, paints, and foods, etc.

- Mandatory for Market Trust & Legal Compliance: BIS certification enables manufacturers in India to comply with the regulations and boost the credibility of their products so that customers can trust them.

Introduction

The BIS Certification for Square Tins under IS 916 secures the guarantee that all square tins manufactured within India meet the quality, safety, and performance laid down by the Bureau of Indian Standards. Square tins find their broad application in packaging and storage for several products, including edible oils, paints, chemicals, lubricants, and food items. Such packages should be resistant, waterproof, non-corrosive, and tough enough to protect the contents against deterioration during storage and transit.

What is IS 916?

IS 916 is an Indian Standard under the Bureau of Indian Standards (BIS), which states the requirements for square tins made of tinplates for packaging and storing items. This standard promotes the manufacture of square tins with appropriate qualities of material, strength, size, and construction, thus facilitating proper storage and transportation of items.

Key Points:

- IS 916 defines the quality of tinplate :used for the manufacture of square tins for durability, strength, and corrosion-resistant purposes.

- Specifies Dimensions and Capacity:It provides guidelines for size, shape, thickness, and capacity to maintain uniformity and consistency in packaging.

- Ensures Proper Construction and Workmanship:It includes seams, joints, edges, and finishing, which are necessary to make the tins leak-proof and strong.

- Suitable for Packaging Various Products :Square tins produced according to IS 916 are mostly used for the storage of edible oils, paints, chemicals, and lubricants, amongst other products.

- Supports BIS certification and quality compliance: Compliance with IS 916 is necessary to procure the necessary BIS certification, such that the product meets the safety, quality requirements of the Indian market, and is marketable.

Why is BIS Certification Mandatory

BIS certification of square tins has to be done as it has been made mandatory by IS 916. Square tins are commonly used for storage and transportation of materials like edible oils, paints, chemicals, and food products, and therefore it is essential that they are sturdy enough, waterproof, and resistant to rust for proper and smooth use. BIS certification guarantees that the manufacturer has adopted the right methods of manufacture and has used suitable materials for the containers to ensure optimal performance and efficiency.

Key Reasons:

- Ensures Product Quality and Safety:BIS certification of square-shaped tins guarantees the quality, strength, and safety of the tins for usage, considering the parameters outlined in IS 916.

- Prevents Leakage and Product Damage:Certified square tins are well produced to ensure safety through tight seams and strong materials to prevent leakage and contamination of the stored items.

- Ensures Compliance with Indian Standards:BIS certification also ensures that the manufacturers are adhering to the guidelines set by IS 916, so that there is uniformity in the materials, dimensions, and construction.

- Builds Market Trust and Credibility: The BIS mark confirms that the square-shaped tin containers are tested and approved for customers. This is likely to boost customer confidence.

- Supports Legal and Regulatory Requirements :Getting certified by the BIS makes it easy for companies to comply with Indian laws, thereby enabling the sale of the square tin containers in both the domestic and industrial markets.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures Standardized Product Quality:In addition, square tins are also BIS certified to guarantee that they are produced following the standard guidelines of IS 916. | Enhances Customer Trust:The BIS mark gives customers a guarantee that their product meets quality and safety standards. |

| Protects Stored Products:These square tins have been certified for their strength, leak-proof quality, and corrosive-resistant properties so that oils, chemicals, food products, and other substances are not damaged. | Increases Market Acceptance :Certified square tins are easily recognized by the market, both for household and industrial use, because of their quality. |

| Promotes Safe Packaging and Handling:BIS certification is a guarantee for proper construction and longevity, thereby minimizing the probability of leakages, ruptures, and accidents during storage and transportation | Improves Brand Reputation:With BIS certification, manufacturers can earn a reputation for producing reliable products |

| Supports Regulatory Compliance: It will ensure compliance with the regulations set by the Indian Standard for the manufacturers. | Reduces Risk of Product Failure: It ensures appropriate materials and construction, which reduces the risk of any leakage, corrosion, or damage. . |

| Improves Product Reliability: By obtaining BIS certification, the reliability of these square tins is ensured, as it is tested and certified. | Provides Competitive Advantage :By being certified by the BIS, the manufacturers hold an advantage in the market as the end-users prefer to purchase quality-approved products only. |

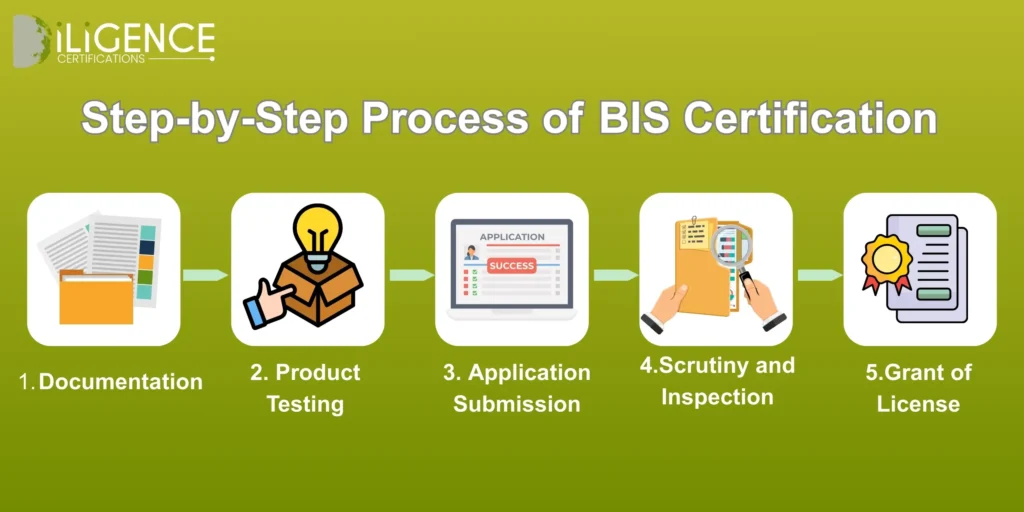

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certification is a renowned consultancy that promises total support for BIS certification of square tins under IS 916. The people at Diligence are experienced and possess thorough knowledge of BIS regulations and documentation processes. This guarantees a hassle-free BIS certification experience for manufacturers. They assist clients at each step of the application filing and BIS license approval.Diligence Certification is a dedicated organization that provides expert support for creating technical documentation, conducting product testing with BIS-approved testing centers, and adhering to all standard requirements.

Conclusion

BIS certification for square tins under IS 916 is a must for ensuring the quality, safety, and performance of the square tins. This, in turn, will ensure the square tins are manufactured with correct material, size, and construction, facilitating the storage and transportation of items like oil, chemicals, paint, and food items.

Frequently Asked Questions (FAQs)

What is BIS Certification for Square Tins IS 916?

It is a certification offered by BIS to ensure the square tins meet quality and safety specifications set out in IS:916.

What does IS 916 cover?

IS 916 defines the material, dimensions, construction, and quality requirements for square tins manufactured from tinplate material.

Is BIS certification required for square tins?

Yes, BIS certification is necessary to ensure compliance with Indian quality and safety regulations, where necessary.

Who issues BIS certification in India?

The official authority responsible for BIS certification is the Bureau of Indian Standards (BIS).

Why is BIS certification important for square tins?

This guarantees that the tins are strong, watertight, resistant to corrosion, and safe for storage and transport.

What are the products stored in BIS-certified square tins?

Square tins are often employed in the storage of edible oils, paints, chemicals, lubricants, and food products.

What is the BIS Standard Mark?

It is an assurance mark given only when the product meets the requirements set by BIS.

Do manufacturers need testing for BIS certification?

Yes, such square tins should undergo testing in BIS-approved laboratories to ascertain their compliance with IS 916.

How does BIS certification benefit manufacturers?

It increases product credibility, ensures compliance, and boosts market acceptance.

How can manufacturers apply for BIS certification?

Companies can apply by own on the BIS portal or seek help from consulting firms such as Diligence Certification.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration