- BIS certification is a guarantee that manufacturers meet the very tough quality and safety standards set for metals that are used in industrial and construction applications.

- Aluminium alloys have become the primary choice of materials in the automotive, aerospace, and infrastructure industries as a result of their excellent strength-to-weight ratio and resistance to corrosion.

- Aluminium Alloy Under IS 617 – 2024 describes the Indian standard details for the chemical composition, mechanical properties, and testing methods of aluminium alloy products.

- It is like a dream come true for Indian manufacturers when they get BIS certification because they can then easily comply with regulations, gain more trust in the market, and also expand their export opportunities.

- The certification journey involves on-site inspections, testing of products in laboratories authorized by BIS, and keeping up with quality standards through continuous checks.

Introduction | Aluminium Alloy

In 2024, a number of Indian metal producers struggled to provide high-quality metals for major infrastructure projects. One of the problems that kept coming up was the conformity of products, especially aluminium, with national quality standards. The Bureau of Indian Standards (BIS) is the organization that has been the most influential in setting, monitoring, and enforcing the standards for everyone that is using materials from one industry to another, with the focus on safety and operational performance. One of the most important has Aluminium Alloy Under IS 617 – 2024, which has turned out to be the main source of reference, is the standard that defines the chemical makeup, the mechanical properties, as well as the testing methods, of aluminium alloys in India.It is not only the manufacturers that Question and answer have to be completely versed in and undergo a certification test by BIS, but also importers and exporters of the product. It is very important to them strategically. Compliance is a way to guarantee the quality of the products and thus, the suppliers‟ loyalty is gained, the company registry problems are avoided, and opportunities for both local and global markets are created.

What is IS 617 – 2024?

IS 617 – 2024 specifies the technical and quality aspects of aluminium alloys. It describes the standard requirements for aluminum alloy products based on elemental composition, physical properties, and different kinds of tests for various industries. As a quality and safety benchmark, the standard requires that aluminium products comply with the performance standards that are possible for the mentioned sectors such as building, vehicle, airplane, and manufacturing.

Key Points:

- It provides the elemental limits for different grades of aluminium alloys to ensure material integrity and performance.

- It reflects the mechanical aspects like tensile strength, hardness, and elongation to concert the material’s durability under industrial conditions.

- It has physical and chemical testing methods for different processes such as heat treatment, corrosion resistance, and microstructure evaluation.

- The standard is for wrought and cast aluminium alloys that are the consumption of industries such as construction, transport, and aerospace.

- It is the groundwork for BIS certification which includes factory inspections, product testing, and compliance audits.

- The instrument lets manufacturers keep consistency, safety, and competitive strength both in local and foreign markets.

Why is BIS Certification Mandatory?

BIS certification is a law and a quality requirement for different products in India, among which are aluminium alloys covered under IS 617 – 2024. The Bureau of Indian Standards (BIS) requires certification to confirm that products conform to the safety, reliability, and performance standards set. BIS certification for producers, dealers, and exporters is more than just a regulatory formality – it is a symbol of confidence and quality assurance that helps the user, the company by increasing its goodwill and facilitating the company’s compliance with the quality standards at the local and global levels.

Key Points

- Defines the material’s chemical composition to make sure that it is made of aluminium alloys and that the material behaves as expected from the chemical, physical, and mechanical points of view.

- Mechanics of the material such as tensile strength, hardness, and elongation are specified in order to guarantee that the materials will be strong enough in industrial conditions.

- Physical, chemical, and metallurgical methods of investigation are also mentioned such as heat treatment, corrosion resistance, and microstructure evaluation for testing the materials.

- The standard is for wrought and cast aluminium alloys with application in industries like construction, transport, and aerospace.

- It lays down the requirements for BIS certification that includes factory inspections, product testing, and compliance audits.

- Manufacturers will be able to maintain the standards of safety, quality as well as be able to compete in the local and global markets through this standard.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| It is the basis for ensuring compliance with Indian legal and safety standards for aluminium alloys. | Improves market credibility and customer loyalty, proving that products are up to standards through a verified source. |

| It is the basis for chemical composition and mechanical properties as per IS 617 – 2024. | Reduces the chance of structural failures and product recalls, thus, safety is assured in end-use applications. |

| Gives the assurance that consumers and end-users are protected through product reliability. | Helps open the door to foreign markets as certified products are recognized globally for their quality. |

| It is the basis for a quality management system through regular audits. | Enhances brand value which can be leveraged for a greater market share in the industrial and construction sectors. |

| It is a demonstration of the implementation of the quality assurance and industry best practices. | It is a way of achieving product quality on a regular basis which results in feweroperational issues and customer complaints. |

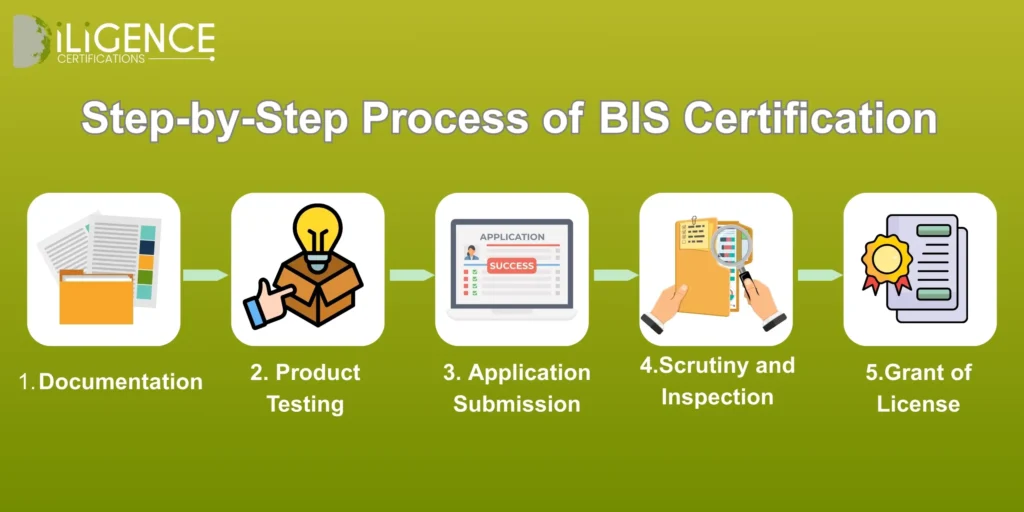

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- Expert Guidance: We have a very strong and knowledgeable team who are very familiar with IS 617 – 2024 standards and BIS procedures. We ensure that your application is technically and regulatorily in accordance with all the requirements.

- Streamlined Process: We are efficient in every step of the process from document submission to lab testing and final approval. This helps to reduce the time and work of the clients.

- Industry-Specific Insights: We are well aware of the problems that the aluminium manufacturing sector may face and therefore, we guide our clients in such a way that they get to compliance faster and also avoid the most common pitfalls.

- Trusted Network: Diligence Certifications has a good rapport with BIS-approved labs and inspectors and, therefore, ensures that audits and testing can be done in a timely manner.

- Continuous Support: We are always on hand after you have been certified to help you with the surveillance audit, renewals, and compliance updates, thus, enabling you to have uninterrupted certification validity.

Conclusion

Getting a BIS certificate for Aluminium Alloy Under IS 617 – 2024 is no longer simply a regulatory requirement, but rather a strategic quality, safety and market credibility investment. Harmonizing with Bureau of Indian Standards gives your aluminium products a green light under very stringent chemical, mechanical and testing standards thus ensuring safety for the end users and instilling confidence in the customers.It is easier to partner with a trusted agency like Diligence Certifications in order to help you go through the process, get rid of the waiting time, and thus be assured that every step from filing the documentation to factory audits and lab testing is done in a professional manner and without wasting time. Firms that prioritize getting a BIS certification not only fulfill their legal obligations but also gain the image of being trustworthy suppliers of good quality products to be able to trade both locally and globally.

Frequently Asked Questions

Is factory inspection required for certification?

Factory inspections are performed by BIS to check if the manufacture of the product and quality control are as per the system.

Is the certification available again after getting approved?

BIS certification can be renewed occasionally. Moreover, it is subjected to continued inspections and compliance audits.

What if these goods are sold without BIS certification?

Products without the proper certification may put their owners in situations where they can be penalized by the authorities, e.g., payment of fines, forced recalls, and legal actions.

What is Aluminium Alloy under IS 617 - 2024?

IS 617 - 2024 is a standard regulated by the Bureau of Indian Standards (BIS) that defines the aluminium alloy standards in terms of quality, composition, and tests.

Who is the releasing authority of IS 617 - 2024?

The Bureau of Indian Standard (BIS) is the main holder, controller, and issuer of the standard.

Is BIS certification necessary for aluminium alloys?

Yes. BIS certification is required for aluminium alloys that comply with the scope of IS 617 - 2024 and are sold in the Indian domestic market (when notified by the government).

Who will obtain a BIS certificate under IS 617-2024?

Manufacturers, importers, and distributors of aluminium alloy products in India are the ones that need to obtain the certification.

Which industries use aluminium alloy as per this standard?

The alloys have been conventionally used by the following industries: Construction, automotive, aerospace, electrical, and general engineering.

What kind of tests need to be done to obtain a BIS certificate?

The tests should specify the chemical composition, mechanical properties, and quality assurance of the material as per IS 617 - 2024.

How long does BIS certification take?

Certification normally takes 30 - 60 days and may vary with the readiness of documents, testing, and factory audit.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration