- Aluminum Alloy Bars Rods offer high strength-to-weight ratios and corrosion resistance.

- BIS Certification for Aluminium Alloy Bars and Rods is mandatory under IS 733:1983.

- Certification ensures quality, safety, and legal compliance.

- Process involves application, testing, inspection, and approval.

- Documents like factory license, test reports, and process details are required.

- License is valid for two years and renewable with compliance checks.

- Benefits include customer trust, global recognition, and market access.

Introduction

Aluminium alloy bars and rods are essential in industries like aerospace, automotive, electrical, construction, and defence. They are commonly chosen for structural and engineering purposes because of their lightweight, strength, and corrosion-resistance properties. In order for aluminium alloy bar and rod manufacturers to sell their products in a market like India, they have to ensure their products meet the required supply standards to ensure safety, quality, and performance. In India, manufacturers must obtain BIS Certification for Aluminium Alloys Bars and Rods under IS 733:1983.

The Bureau of Indian Standards (BIS), which is India’s National standards body, has made compliance mandatory for manufacturers and importers to BIS Certification, which means without obtaining certification, business can not legally manufacture, supply, or sale aluminium alloy bars and rods in the Indian market.

What are Aluminum Alloy Bars And Rods?

Aluminum alloy bars & rods are manufactured forms of metal, which provide structural and functional applications in a number of industries.”

At its most basic level, aluminum alloy bars & rods, are long solid metal forms (circular, rectangular, or square) made from an alloy of aluminum and other metals including magnesium, silicon, copper, or zinc to improve and enhance strength, corrosion resistance, and workability.

These metal forms are not pure aluminum and rather, these are engineered alloy products developed to ensure a certain level of mechanical properties. Think of them like the structural element in many components: automobile chassis, bicycle frames, aerospace components, machine housings and more.

Key attributes:

- High strength to weight ratio

- Great corrosion resistance (especially in marine and outdoor use)

- Good machinability and weldability

- Long life cycle, recyclable, and non-toxic

What is IS 733:1983?

IS 733:1983 is the Indian Standard allocating requirements for wrought aluminium and aluminium alloy bars, rods and sections. The standard ensures:

- Chemical consistency

- Dimensional accuracy

- Mechanical properties (tensile strength, hardness, elongation)

- Heat treatment conditions

- Surface finish and quality

When following this standards, manufacturers can ensure that their products will be safe, durable and reliable.

Why is BIS Certification for Aluminium Alloy Bars and Rods Mandatory?

- Quality Assurance – Guarantees that the quality of aluminum alloy bars and rods aligns with IS 733:1983 norms.

- Market Access – Legal requirement for selling products in India.

- Public Safety – Eliminates the risks associated with selling poor quality or the unsafe alloy.

- Global Acceptance – Gains consumer trust in the domestic and global markets.

- Legal Requirement – Non-compliance could lead to penalties, fines, or product ban.

Types of Aluminum Alloy Bars & Rods

| Round Bars | Common diameters 6mm–200mm. 6061-T6 round bars fit milling, turning, and shaft applications. |

| Hex & Square Bars | Used for structural components—hex bars for fasteners, square for architectural profiles. |

| Flat & Forged Bars | Ideal for heavy machining—flat bars for frame members, forged rods for high-stress parts. |

| Customized Profiles | Rolled or extruded sections based on drawing—great for trim, brackets, or custom hardware. |

Understanding IS 733:1983

IS 733 1983 is the Bureau of Indian Standards specification for technical requirements of BIS Certification For wrought aluminum and aluminum alloy bars rods, and sections. Such specification does set the conditions for chemical compositions and mechanical characteristics, manufacturing methods, and tests against which any manufacturer must apply and adhere to for quality assurance of the products.

Key Features of IS 733:1983

Chemical Compositions

It is intended that a specification under this heading shall treat the permissible content of copper, magnesium, silicon, manganese, with an allowance for zinc in aluminum base alloys. The limits will in themselves ensure the correct mechanical properties, resistance to corrosion, and hence machinability of the materials suitable over a wide range of engineering applications.

Mechanical Properties

The mechanical properties included in IS 733:1983 are tensile strength, yield strength, and elongation which describe the ability of the material to withstand various loads and stresses applicable to engineering. They are also required to be substantiated in the production of the materials by controlled processes and tests.

Manufacturing Process

BIS Certification for wrought aluminum and its alloys are basically mechanically wrought using rolling, extrusion, or forging processes. Refinement of grain structures usually follows these methods for better mechanical properties and surface finish in the finished product. The practices given in IS 733:1983 are to act as a guide to ensure that the process followed remains in accordance with the requirements for quality.

Product Dimensions and Tolerances

It specifies dimensions and tolerances acceptable for the aluminum alloy bars rods, and sections. Compliance with those specifications is major to their use in many engineering components and systems and avoids problems relating to assembly.

Testing and Quality Control

The specifications of IS 733:1983 require products to be adequately tested to comply with the said specifications. Tests usually consists of chemical analyses, to ascertain materials composition, mechanical tests carried out to determine strength and ductility, and dimension checks for accuracy. It is mainly for reliability and performance in product quality assurance processes.

Key Highlights :-

| Standard Name | IS 733:1983 |

| Materials Type | Includes aluminum and its alloys in various wrought forms like bars, rods, and extruded sections. |

| Chemical Composition | Specifies permissible limits of elements like aluminum, silicon, iron, copper, manganese, magnesium, zinc, and others. |

| Testing Requirement | Specifies tests for mechanical properties, chemical composition, dimensional accuracy, and surface finish. |

| Quality Control | Manufacturers must maintain a quality management system and records of production and testing. for full QCO update click here |

Application fee

The application fee for BIS Certification of Aluminum Alloy Bars & Rods is quite modest: it usually falls between depending on the certification scheme. The application fee is a one-time payment made when submitting your application on the BIS portal.

Remember, the application fee is not refundable. Although the application fee seems like a tiny step, it is the official start to your compliance journey for either IS 733 or IS 644.

The validity of the BIS Licence

- Initial BIS Certification is granted for 2 years from the date of issue.

- Thereafter, it can be renewed in 1-year or 2-year blocks, depending on compliance history and consistency of the product.

- Renewals are mostly routine where quality management is maintained, and there are no major non-conformances.

Documents Required for BIS Certification

To apply for a BIS Licence for Aluminum Alloy Bars & Rods under IS 733 or IS 644, manufacturers need to submit:

- Previous certification (if any)

- Test Reports from a BIS-recognised lab

- Manufacturing Process Flowchart

- Factory Layout and Machinery Details

- Quality Control Manual (QCM)

- Legal Identity Proof (Udyam, GST, PAN, etc.)

- Authorised Signatory ID & Signature

- Proof of Factory Ownership or Lease

- List of Raw Materials and Suppliers

- Calibration Certificates of Instruments

Step-by-Step BIS Certification Process

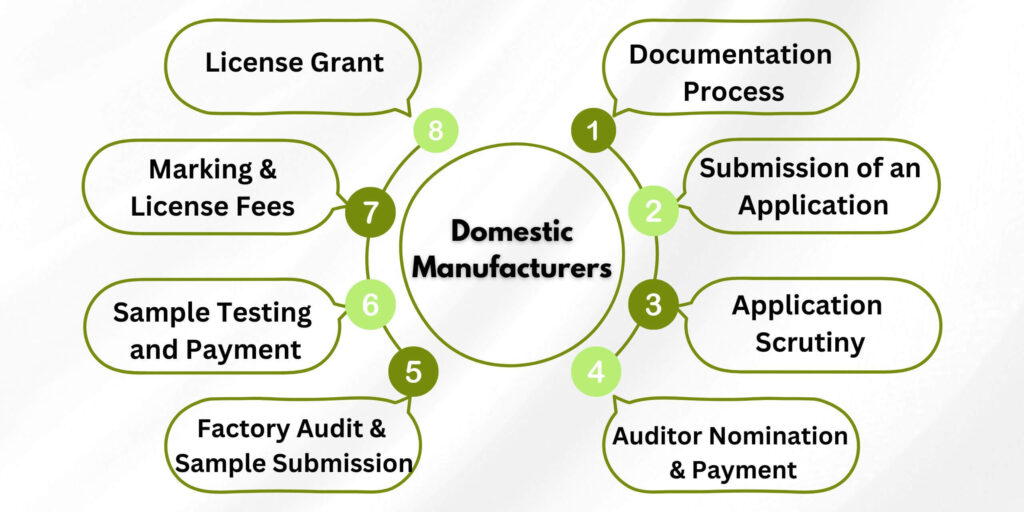

For Domestic Manufacturers (ISI Mark Scheme):

- Application Submission on ManakOnline portal with basic details and documents

- Factory Audit by BIS Officer, including equipment check, records review, and sample collection

- Product Testing by BIS-approved laboratory

- Review of Test Results and inspection report

- Grant of License with permission to use ISI mark

- Marking Fee Payment and regular surveillance audit every 6–12 months

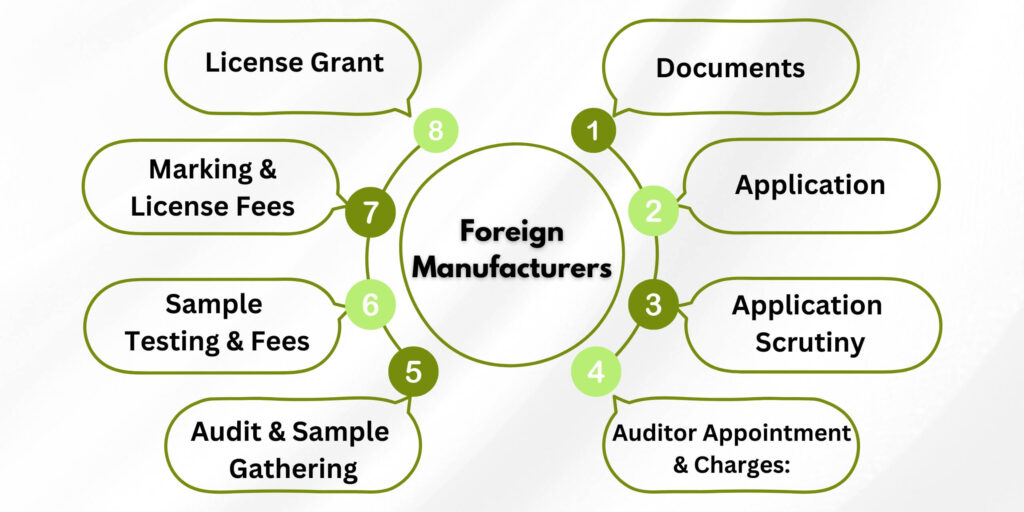

For Foreign Manufacturers (FMCS Scheme):

- Nominate an Authorised Indian Representative (AIR)

- Submit a detailed application via FMCS portal

- Pre-audit payment & document scrutiny

- Foreign Inspection Visit by BIS delegation

- Local testing of samples in India

- Grant of BIS Licence with ISI marking approval

Diligence Certification: Ensuring Compliance with IS 733:1983

Diligence Certifications is committed to ensuring that the producer is complying with IS 733:1983 to manufacture high-grade BIS Certification for wrought aluminum and aluminum alloy products. The certification service consists of thorough assessments and evaluations to confirm conformity of products to all the criteria mentioned under the standard.

Why Choose Diligence Certifications?

- Compliance Expertise: With over a decade long experience into over-the-counter certification and compliance, Diligence Certifications has become the trusted partner of manufacturers across industries.

- Complete Evaluation: Our team carries out thorough inspections and tests on products for IS 733:1983 to give an edge to manufacturers.

- Market Credibility: Certification by Diligence Certifications will add credibility in that product and will increase market acceptance.

- Customized Support: We provide the custom-tailored guidance to support every manufacturer’s unique needs for a seamless certification process.

Benefits of Compliance with IS 733:1983

- Elevated Quality Assurance: It sanctions compliance to the highest-quality standard norms on products.

- Regulatory Compliance: Certification proves products are true with respect to Indian regulatory concerns.

- Improved Market Access: IS 733:1983 compliance certification grants products superior acceptance within national and international areas.

- Customer Satisfaction: High-quality, reliable products lead to greater customer trust and loyalty.

Conclusion

IS 733:1983 is a significant standard laying down the quality requirements for wrought aluminum and aluminum alloy bars, rods, and sections. The standards represent a core criterion in mechanical properties, chemical composition, dimensions, and reliability. An implementation of IS 733:1983 allows manufacturers to make materials that are resistant to wear, high in performance, and consistent with diverse engineering requirements across various industries such as automotive, aerospace, construction, and general engineering.

Being a pioneer compliance support organization, it aims to assist manufacturers in complying with the more stringent IS 733:1983. This would include consulting on the testing of materials, optimizing processing conditions, and establishing quality assurance practices to seamlessly meet the requirements of BIS Certification. Complying with the standard adds value to manufacturers on the quality and reliability of their products while one may earn an uncontested opinion in the market.

With the help of dedicated efforts, Diligence Certification has closed the gap between regulations and market expectations, assisting manufacturers in competitive markets by operating at the highest quality standards.

Frequently Asked Questions

What are aluminum alloy bars and rods typically used for?

They are frequently used for parts that require high strength but reasonable weight in aerospace, automotive, construction, and general engineering.

Are aluminum alloy bars and rods corrosion resistant?

Yes, particularly alloys like 6061 and 6082. These rods have very good resistance to weathering, making them suitable for marine and outdoor use.

What is the difference between a bar and a rod?

Rods tend to be round and used in machining applications, while bars can be flat, square, or hexagonal, and are primarily used for structural applications.

Which standard apply to aluminum alloy bars and rods in India?

Standards enforced by the Bureau of Indian Standards (BIS), such as IS 733 and IS 644. This ensures a certain level of acceptable quality of the product.

Are aluminum alloy rods good for welding?

Yes. Most aluminum alloys are weldable but you should always try to match the alloy grade, and filler metal if possible, of the base material to achieve the best results.

What methods are used in the manufacture of aluminum alloy bars & rods?

Aluminum bars and rods are manufactured in the vast majority of cases by means of extrusion or rolling, after which they will then receive heat treatment and be cut to the length specified by customers or the end user in many cases.

Is BIS certification needed for aluminum alloy rods?

It is generally required by law to have a BIS certification for aluminum alloy rods with many industrial and defence applications in India to ensure safety and conformity of product types.

What is the most common grade of aluminum rod?

6061-T6 and 6082-T6 are the most commonly used grades of aluminum rod on the market due to their strength, machinability and corrosion resistance.

Will aluminum rods work for CNC machining?

Yes. Aluminum rods are ideal for CNC turning and milling because of the heat, levels of surface finish and tool wear.

Where can I purchase BIS certified aluminum alloy bars in India?

This information can be attained through certified manufactures or suppliers on BIS.gov.in. You can also approach suppliers of certified products directly and request documentation

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration