- BIS Certification for Tin Ingots ensures compliance with Indian Standards for metal purity and manufacturing quality.

- This mandatory certification is governed by IS 26:2024.

- Manufacturers, both domestic and foreign, must obtain a BIS license before selling tin ingots in the Indian market.

- The certification process includes product testing in BIS-approved labs, application review, and factory inspection.

- It assures industrial buyers and OEMs of the product’s metallurgical integrity.

- Timely certification aids smooth market entry, avoids penalties, and builds brand trust.

Introduction

Through the introduction of the TIN Ingot Quality Control Order, 2025, the Government of India ( Ministry of Mines) has taken a significant step in enhancing industrial materials’ quality and safety standards. With the emphasis on the Bureau of Indian Standards (BIS), this command made it obligatory on the part of manufacturers and importers of tin ingots to fulfill given quality requirements under the certified scheme of BIS. BIS Certification for Tin Ingots ensures that tin ingots meet the quality and safety standards as mandated by the Bureau of Indian Standards.

Tin ingots play key roles in various industrial applications such as electronics, automotive parts, and packaging. The standardization of tin ingots is vital for product integrity and consumer safety. With the new quality control order.

Diligence Certification is engaged to assist businesses in various compliance mandates, such as the BIS Quality Control Orders. Whether your business is domestic or an importer, our expert consulting team can provide complete support to permit effortless BIS registration and compliance with all regulations.

IS 26:2024 Introduces Tin Ingots.

The IS 26:2024 standard has been organized to serve as a quality benchmark for refined tin ingots, which are an important material for soldering, plating, the production of alloys, and packing. This standard underwent an amendment in 2024 and has since been incorporated under the mandatory BIS certification scheme according to the 2025 Quality Control Oder. This would mean that the tin ingots consumed in Indian industries meet the highest standards of purity and quality.

Scope of IS 26:2024

According to IS 26:2024, the regulations apply to refined tin produced from tin ore or secondary tin-bearing materials and are in the form of ingots. The tin ingots are of great use in various industries, such as soldering, electroplating, making alloys, and coating operations.

This specification will guarantee uniformity in the quality and performance of tin ingots by establishing uniform criteria for classification, chemical composition, manufacturing, inspection methods, and sampling.

Classification and Grades of BIS Certification for Tin Ingots

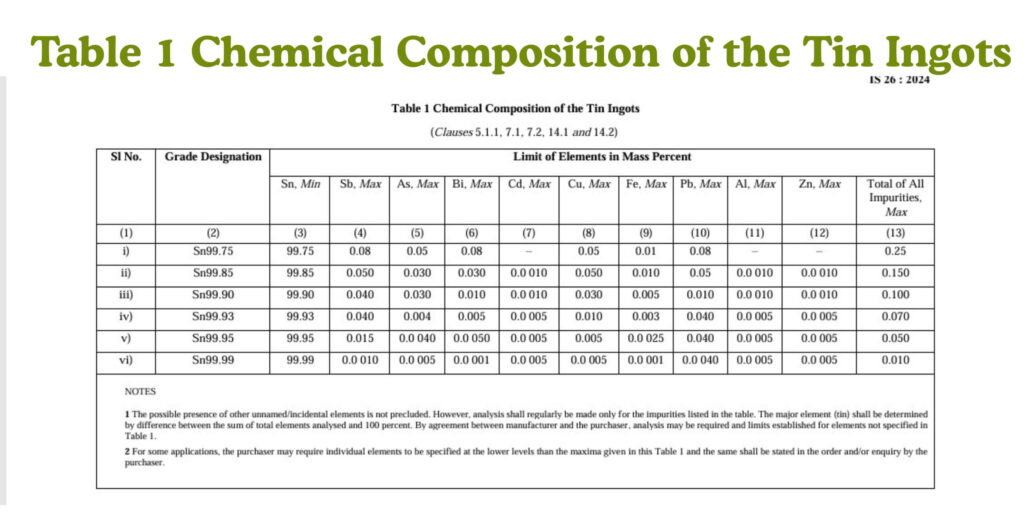

The refined tin ingots are categorized into six grades, based on the minimum tin content. Each grade represents a different purity level, making it suitable for a variety of applications. The grades are:

- Sn99.75 – Minimum 99.75% Tin

- Sn99.85 – Minimum 99.85% Tin

- Sn99.90 – Minimum 99.90% Tin

- Sn99.93 – Minimum 99.93% Tin

- Sn99.95 – Minimum 99.95% Tin

- Sn99.99 – Minimum 99.99% Tin (Ultra-high purity)

This classification enables buyers to select the appropriate grade based on their application’s requirements, from basic soldering needs to high-precision electronic components.

Who Needs BIS Certification for Tin Ingots?

The BIS Certification for Tin Ingots isn’t limited to just large-scale producers. In 2025, the Quality Control Oder (QCO) mandates that anyone involved in the supply, import, or distribution of tin ingots must comply.

Here’s a list of businesses that require BIS Certification under Indian law:

- Tin Ingot Manufacturers – Whether you’re a domestic factory or a foreign supplier, certification under IS 813:1986 is compulsory for legal sale.

- Exporters Targeting Indian Buyers – Even if your operations are outside India, BIS Certification is required before shipping tin ingots into the country.

- Importers and Stockists – Distributors storing or trading tin ingots in India must ensure every batch carries valid Certification for Tin Ingots with the ISI mark.

- Electronics, Soldering, or Alloy Manufacturers – Companies sourcing tin ingots for secondary manufacturing (like circuit boards or tin-based alloys) also fall under QCO mandates.

- Private Label Sellers and Warehouse Operators – If you’re rebranding or warehousing certified tin, the compliance burden still lies with you.

BIS QCO 2025 for Tin Ingot IS 26:2024

Supply of Material – Raw Materials and Manufacturing

According to Clause 6 of the standard, the refined tin ingots should be manufactured from either:

- Primary tin ore,

- Secondary tin-bearing materials (recycled content), or

- A combination of both.

Acceptable Methods of Refinement

The BIS permits the following manufacturing techniques to achieve the desired purity levels:

- Fire Refining

- Vacuum Refining

- Electrolytic Refining

- Electrowinning, or

- Any combination of the above methods.

These refining techniques ensure the removal of impurities and help manufacturers attain the prescribed grade of tin under this standard.

Chemical Composition

Tin ingots have to be chemically pure. The chemical composition has to match the standards specified in Table 1 given in this standard.

Analytical methods: Either those defined in IS 1940 or any accepted instrumental/wet chemical methods.

In case of a dispute, IS 1940 shall be the referee method. For whatever element, IS 1940 does not apply, the method shall be decided upon by mutual agreement between the buyer and the supplier.

This will ensure total quality assurance with transparency and verification throughout the supply chain.

Inspection & Testing

Core to any BIS Certification is Quality Assurance. Under BIS Certification for Tin Ingots IS 26:2024, -these provisions:

- The manufacturer shall undertake all inspections unless any variation has been agreed upon.

- The tin ingots may be inspected at the site of the supplier at the purchaser’s choice.

- The supplier is obliged to provide all facilities necessary for inspection, sampling, and testing.

- The testing processes may be witnessed by the purchaser’s representative.

Such modalities ensure transparent, standardized testing procedures that instill trust in a supply chain.

Marking & Packaging Requirements

Each certified tin ingot must carry appropriate BIS marking and labeling to signify conformity. The marking must include:

- Manufacturer’s identification

- Batch or lot number

- Grade of tin ingot

- BIS Standard Mark (after certification)

This labeling is critical for traceability, accountability, and regulatory compliance, especially in international trade.

General Supply Requirements (IS 1387 Compliance)

As per IS 1387, general supply and packing requirements for tin ingots are to be maintained. This covers provisions that specify:

- Uniformity of size and shape of the ingot

- Stacking patterns suitable for transport

- Protection of the shipment from corrosion and contamination

- Packaging and documentation for traceability purposes

Documents Required for BIS Certification

Manufacturer Documentation Requirements

- Premises Documentation

- GST Certificate

- Udyam Aadhar (MSME Certificate)

- Process Flow Chart

- Owner Identification

- Trademark Certificate/Brand Name

- List of Raw Materials

- Production Process Description

- Factory Location

- Plant Layout

- Machinery List

BIS Certification Process for Tin Ingots

The new mandatory certification standard has now made it compulsory for manufacturers and importers to have a BIS License for the sale of tin ingots in India. This is a step-by-step overview:

- Documentation Preparation – Gather required documents like factory license, quality control plan, and raw material specifications

- Application Submission- Apply online and upload required documents like factory layout, test reports, quality control plan, etc. at the BIS portal.

- Product Testing – Sample tin ingots have to be sent to an BIS-approved laboratory for chemical composition testing.

- Factory Inspection – BIS officers will check the way of production process, quality control setup, and labeling system.

- Grant of License – On successful inspection and test report verification, BIS issues the license to use the Standard Mark.

Why BIS Certification for Tin Ingots Matters

Here are the features that make the 2025 BIS QCO BIS Certification for Tin Ingots a real game-changer:

- Standardization for Quality: Ascertains purity levels essential for downstream industries.

- Consumer Acceptance: The BIS mark provides confidence to buyers and end-users.

- Market Access: Obtaining BIS Certification is mandatory for sale/import into the domestic market.

- Ready for Export: It boosts credibility in markets abroad.

- Regulatory Compliance: Mitigates penalties and avoids recalls.

Diligence Certification: Your BIS Compliance Partner

Diligence Certification provides expert consultancy for manufacturers and importers seeking BIS Certification for Tin Ingots under IS 26:2024. Our services include:

- Application filing & documentation

- Lab coordination & sample testing

- Factory audit support

- Liaison with BIS officials

- End-to-end certification management

We simplify compliance so that you can focus on manufacturing.

Conclusion

The 2025 QCO has made it mandatory that tin ingots are certified by BIS under IS 26:2024, thereby ensuring that only quality and standardized products enter the Indian market. This standard covers every essential aspect of production, from grade classification to chemical composition to inspection protocols. All manufacturers and importers must follow BIS standards before they can sell or distribute tin ingots legally.

Diligence Certification eases the whole certification process, from documentation to license grant, thus making sure compliance with BIS norms is done timely manner. Connect with us to make your tin ingots BIS-certified and market-ready!

Frequently Asked Questions

Are tin ingot exporters required to be BIS certified?

Yes, exporters must obtain BIS certification to sell or supply tin ingots in India as per IS 917:2021.

What is the expected timeline to obtain BIS for tin ingots?

Typically between 30-45 days assuming all documentation is complete as well as testing, inspections, and approvals.

Can traders and dealers apply for BIS certification?

No, only manufacturers can apply. Traders and dealers can only distribute certified products that were manufactured by a licensed manufacturer.

What are the penalties if a business does not comply with the certification requirements?

Penalties include numerous fines, a ban on importing the product(s), seized inventory without reimbursement, and cancellation of trade license(s).

Do recycled tin ingots need BIS certification?

Yes, as long as the final product is the same as listed in the standard or if it is sold commercially, you will need to get certified.

How often are BIS audits conducted?

Typically only once a year or when the licence needs to be renewed. BIS may also do surprise audits.

Can a single license cover multiple grades of ingots?

Yes, as long as they are in the grades of IS 917 and you manufacture all of the grades together on the same site, with the same quality plan.

Do lab test reports have to be from a certain lab?

Yes, the only recognized laboratories are those under BIS

Will getting a BIS certification help export the product?

Yes, BIS certification simplifies buyer trust from buyers in different parts of the world and is often seen as a benchmark for quality.

What happens if the sample fails in lab testing?

You must re-test or fix your process. Application may be put on hold or rejected.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration