- BIS Scheme X Certification for all types of weaving machines (looms) and their assemblies, sub-assemblies & components ensures standardized quality, safety, and interoperability across India’s textile machinery sector.

- From rapier and air jet looms to dobby mechanisms, manufacturers must comply with BIS norms under Scheme X.

- This certification is mandatory under Quality Control Orders.

- It helps gain market trust, ensures eligibility for government tenders, and aligns your products with Make in India goals.

- Certification covers complete looms as well as parts like shedding, picking, and let-off assemblies.

Introduction

In 2022, a mid-sized textile machinery manufacturer from Panipat named Arvind Engineering faced a rude shock. A large export order to Sri Lanka got abruptly cancelled. The reason? Their high-speed air-jet looms lacked valid BIS Scheme X Certification. Despite having ISO standards and CE marking, the lack of BIS compliance rendered their consignment illegal under India’s Quality Control Order (QCO). It wasn’t just a legal formality—it cost them over ₹40 lakhs in losses.

This scenario isn’t rare anymore. Since the Ministry of Textiles issued mandatory BIS certification for weaving machines and their sub-systems, non-compliance has gone from risky to downright disastrous. But there’s a clear path forward.

Whether you manufacture complete looms, import components, or assemble weaving machinery, BIS Scheme X certification is not optional—it’s the foundation of your market access and legal validity in India today.

What Is BIS Scheme X Certification?

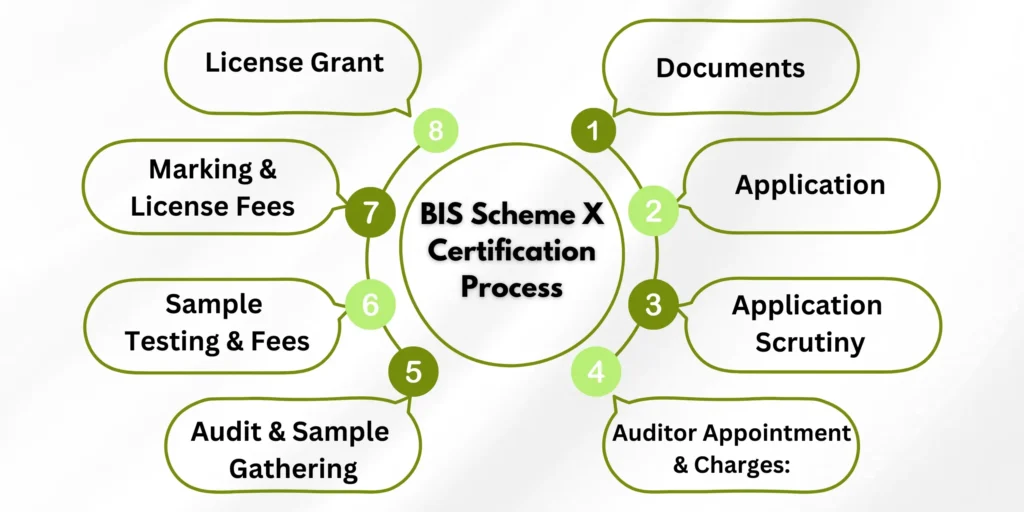

Scheme X is part of the Bureau of Indian Standards (BIS) product certification framework. Unlike the older self-regulation models, Scheme X involves:

- Application and scrutiny

- Product testing by BIS labs

- Factory inspections

- Certification grant

- Ongoing surveillance

For weaving machines, the Government of India enforced QCOs (Quality Control Orders) that mandate BIS registration under Scheme X.

The scheme applies to all types of looms and weaving assemblies, including:

- High-speed rapier looms

- Air jet looms

- Water jet looms

- Dobby, Jacquard, and cam shedding systems

- Sub-assemblies and key components like let-off, take-up, shedding mechanisms

The goal? Standardization. BIS Scheme X ensures safety, compatibility, and performance across manufacturers and importers. It’s particularly crucial for government buyers, EPCG scheme exporters, and MSMEs looking to scale.

Why BIS Certification Is Essential for Looms & Weaving Parts

The QCO-backed BIS certification is more than paperwork. It’s a business-critical compliance layer that:

- Avoids legal penalties: Selling non-certified weaving machines in India violates BIS Act provisions—this invites penalties, confiscation, and even imprisonment.

- Secures buyer trust: EPCG licensees, government PSUs, and private brands increasingly demand BIS-certified components to ensure product quality and audit trail.

- Enables exports: BIS approval acts as a domestic quality benchmark, often helping with cross-border compliance negotiations.

- Unlocks schemes: Make in India, Startup India, and PLI scheme eligibility often hinge on product certifications including BIS Scheme X.

Without BIS, you’re not just non-compliant—you’re invisible to major institutional buyers.

Which Machines and Parts Fall Under Scheme X Certification?

One of the most common misconceptions is that only full weaving machines need certification. In reality, the QCO makes it clear:

All types of looms and their assemblies, sub-assemblies, and components must be BIS certified.

Here’s a breakdown:

Loom Types:

- Rapier looms

- Air jet looms

- Water jet looms

- Projectile looms

Major Sub-Assemblies:

- Shedding mechanisms (cam, dobby, jacquard)

- Picking systems (pneumatic, mechanical)

- Beat-up systems

- Take-up and let-off assemblies

Components:

- Drive motors

- Electronic control units

- Sensors and encoders

- Heald frames, reed systems

- Yarn tensioners and brakes

Even if you supply just one part—like a cam for a jacquard—Scheme X applies.

Classification of Weaving Machines

Hand Looms

- These are simply hand-operated looms.

- They are used by artisans, who are many of them in rural ways all over India and ethnic fabrics.

Power Looms

- These are looms that run on mechanization and electric power.

- They have a higher productivity advantage over hand looms.

Automatic Looms

- These are automatic looms with shuttle replacement, break fixing mechanisms, and so on.

- Suitable for mass production

Shuttle Looms

- Traditional looms that shuttle with weft run inside it

- They are slower and have a higher maintenance cost.

Shuttleless Looms

These are fast modern looms that are mostly used in factories.

- Air Jet Looms: These are the looms that operate with compressed air to propel the weft.

- Water Jet Looms: Propel the weft with much water and are good for hydrophobic yarns.

- Rapier Looms: Employs a mechanical arm to carry yarn.

- Projectile Looms: A small projectile carries weft yarn.

- Multiphase Looms: Use many shed openings for high-speed production.

Assemblies, Sub-Assemblies and Components of Weaving Machines

Each weaving machine is built of very complex parts and systems:

Major Assemblies:

- Warp Beam Assembly

- Heald Frame Assembly

- Reed & Beater Assembly

- Take-up & Let-off Assembly

- Shuttle Assembly (for shuttle looms)

- Weft Insertion Mechanism (for shuttleless looms)

Subassemblies and Components

- Gears and Driving Mechanisms

- Control Panels and Sensors

- Pneumatic or Hydraulic Units (for Air/Water Jet Looms)

- Electronic Jacquards

- Fabric Rollers

- Warp Stop Motions

- Lubrication

- Tension Control Units

Benefits of BIS Certification for Loom Manufacturing Industry

For manufacturers

- Improved brand reputation

- Better access to government tenders

- Compliance with Make in India Norms.

For exporters

- Worldwide recognition.

- Increased credibility in the eyes of customers.

For the buyers

- Safe and fit for use

- Standard specification for compatibility with machines.

Checklist before your apply

- Verify the product type under the BIS Scheme X

- Last minute preparations of the product testing samples

- Collect technical and factory documentation

- Choose a BIS-recognized lab

- Consult with Diligence Certifications

- Apply in online mode and pay the fees

- Prepare for a factory inspection

Step-by-Step Guide to BIS Certification for Weaving Machines

- Application Submission: Submit a valid Form V under the BIS Scheme X with details of your product.

- Document Verification: The firm gives its technical specifications, test reports, and factory layout for its products.

- Testing: The machines/components need to be tested at BIS-recognized testing laboratories.

- Factory Inspection: MIS officials will inspect the production and quality processes as part of its normal monitoring.

- License Grant: The final issuance of a BIS license for the company follows adherence to the guidelines specified above.

Required Documents for BIS Scheme-X Certification

To obtain certification from the BIS, there is quite a detailed documentation required. Below is the list of essential documents required for weaving machines, assemblies, sub-assemblies, or components under Scheme X:

List of Required Documents

- Application Form (Form V)

- Certificate of Registration of Company

- Factory License

- Process Flowchart of Manufacturing

- Technical Drawings & Specifications

- Product catalogues, drawings and specifications

- BOM (Bill of Materials)

- Quality Control Manual

- Internal Testing Processes

- Calibration Certificates of Equipment

- Should match with relevant IS standard

- Factory Layout Plan

- List of Manufacturing Equipment and Testing Equipment

- Details of Sub-Assemblies or Imported Components

- Power of Attorney (If application is filed through an agent)

- Duly filled Undertaking of Compliance

- Invoices Copies (optional for importers)

Note: All documents will be self-attested and submitted in soft and hard copies as required by BIS.

Validity and Renewal

The certificate remains in force for 2 years.

The certificate requires annual surveillance and renewal.

Cost of BIS Certification for Weaving Machines Under Scheme X

At Scheme X, costs for BIS certification depend on a variety of factors, including type of product (complete weaving machine, assembly, or component), number of variants, types of tests required, and location of the manufacturing site.

All costs for actual testing, inspection, and certification shall be charged on an actual basis by the BIS and its associated service providers.

| Cost Category | Details |

| BIS Application Fee | As per actual BIS fee structure (depends on product category) |

| Testing Charges | Charged by BIS-recognized labs per product/variant |

| Factory Audit/Inspection Charges | Includes professional fee + travel and lodging of BIS officials |

| BIS License Fee (2 years validity) | Based on product category and number of manufacturing units |

| Annual Renewal/Surveillance Fee | Billed as per BIS guidelines during renewal or audit |

| Consultancy Charges | Diligence Certifications charges based on project complexity and scope |

What Are the Factors That Determine the Final Cost?

The Final Cost normally is determined based on

- The number of products/variants submitted for certification

- The complexity of testing (physical, electrical, safety, performance)

- Domestic components versus foreign ones

- Location of your manufacturing unit

- The readiness of your manufacturing unit

- Need for multiple factory inspections, if needed

- Whether a product needs rectification or re-testing

Since BIS and lab charges vary from case to case, it is suggested that a formal quotation be requested against your specific machine type and scope of certification.

How Diligence Certifications Helps You Get A BIS Scheme X Certification

Diligence Certifications is one expert consultancy that helps manufacturers and importers in obtaining BIS, ISI, and other compliance certification in India.

Services Provided by Diligence Certifications

- Product feasibility study

- Documentation & application submission

- Liaising with Bureau officials

- Laboratory tests coordination

- Factory inspection assistance

- Total compliance consulting

Why choose Diligence Certification?

- 100% success rate for BIS approvals

- Certified engineers and auditors

- Support across India with international clientele

- Fast-track certification

- Affordable and transparent feeing

Conclusion

The boom in textile production is being watched by the world, and the most important point in this dimension is the standardization through BIS Scheme X. Whether it is a domestic manufacturer or an importer of a weaving machine and its parts, it should be BIS certified.

Diligence Certifications offers you an excellent partner to meet all technical, documentation, and inspection requirements without any hassles. Invest in compliance; begin weaving a trusted future base for manufacturing.

Frequently Asked Questions

What is BIS Scheme X Certification for Weaving Machines?

The BIS Scheme X Certification is a compulsory quality certification given by the Bureau of Indian Standards (BIS) for weaving machines (looms) and their assemblies, sub-assemblies, and components.

Why is BIS Scheme X Certification required for Weaving Machines?

BIS Scheme X Certification is necessary to guarantee product quality, durability, and safety. It helps manufacturers comply with government regulations, improves market credibility and customer trust in weaving machines and their parts.

Which types of weaving machines and components are covered under BIS Scheme X Certification?

The BIS Scheme X encompasses:

Power looms & automatic looms

Handlooms & semi-automatic looms

Jacquard looms, rapier looms, air-jet looms, and water-jet looms

Assemblies & sub-assemblies such as beams, heddles, shuttles, and warp let-off mechanisms.

Who needs to Apply for BIS Scheme X Certification for Weaving Machines?

Manufacturers, importers and sellers of spinning machines and their parts need to have BIS Scheme X Certification to sell their equipment within India.

What is the process for obtaining BIS Scheme X Certification for Weaving Machinery?

Operation of the Facility: Such a proposal certifies appending the

Application filed along with details of the product.

Carryout Factory inspection by BIS officials.

Testing at an approved BIS laboratory.

What are the key benefits of BIS Scheme X Certification?

Compliance with Indian legal standards.

Enhanced market access and customer trust.

Improved quality assurance for weaving machines and components.

Competitive edge over uncertified products.

How long does it take to get BIS Scheme X Certification for Weaving Machines?

It takes 4-8 weeks, usually depending on product testing and inspection outcomes.

What are the penalties for selling weaving machines without BIS Certification?

The assessment of non-compliance could involve fines, litigation, product embargoes, or stoppage of sale under these standards, according to the BIS regulations and prevailing Indian laws.

How Much Does BIS Certification Scheme X Cost?

Costs are subject to change based on the product category, testing requirements, and BIS registration fees. Manufacturers should seek detailed cost estimations from BIS or a certification expert.

How can Diligence Certifications help with BIS Scheme X Certification?

Diligence Certifications has been presented with the expert guidance documentation support coordination for lab testing and the end-to-end assistance for BIS for weaving machines.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration