- Quality and Safety Assurance :BIS instrument ensures that cold reduced electrolytic tinplate meets strict quality, strength, and safety conditions for packaging and artificial operations.

- Coating and face Finish Conditions :The standard defines drum coating consistency, uniformity, and face finish to insure erosion resistance and product continuity.

- Mechanical and Chemical Property Compliance :IS 1993:2018 specifies limits for tensile strength, temper grade, and chemical composition to insure harmonious performance.

- Mandatory Certification for Market Accessits certification is obligatory for manufacturers and importers to vend electrolytic tinplate in the Indian request.

- Testing, examination, and BIS Marking :Products must suffer testing in BIS- honored laboratories and, upon blessing, carry the BIS Standard Mark to confirm compliance with IS 1993:2018.

Introduction

Cold Reduced Electrolytic Tinplate( CR ETP) is a thin steel distance carpeted with drum through an electrolytic process to give erosion resistance, continuity, and excellent face finish. It’s extensively used in packaging operations similar to food barrels, libation barrels, closures, and holders. The Indian Standard IS 1993:2018 specifies the conditions for cold reduced electrolytic tinplate, including chemical composition, mechanical parcels, coating mass, and face finish. BIS certification under this standard ensures that the tinplate meets the prescribed quality, safety, and performance criteria. Manufacturers and importers must gain BIS certification to fairly vend and distribute CR ETP products in India, icing trustability and compliance with public quality standards.

What is IS 1993:2018?

IS 1993:2018 is an Indian Standard published by the Bureau of Indian Standards( BIS) that specifies the conditions for Cold Reduced Electrolytic Tinplate( CR ETP). This standard covers thin sword wastes that are cold, reduced to precise consistency and carpeted with drum through an electrolytic process to give superior erosion resistance, face finish, and continuity. The drum coating helps cover the sword base from rust and chemical responses, making it suitable for packaging sensitive products similar to food, potables, canvases, maquillages, and chemicals. The standard defines important specialized parameters including chemical composition, mechanical parcels, temper grades, drum coating mass, face finish, dimensional forbearance, and quality conditions.

Key Points:

- Indian Standard for Electrolytic Tinplate :IS 1993:2018 specifies the conditions for Cold Reduced Electrolytic Tinplate( CR ETP), which is sword carpeted with drum to ameliorate erosion resistance and continuity.

- Defines Technical and Quality Conditions :The standard covers chemical composition, mechanical parcels, temper grades, coating mass, and face finish to insure harmonious product performance.

- Ensures felicity for Packaging operations :It ensures the tinplate is safe and dependable for use in food barrels, libation holders, closures, and other packaging operations.

- Specifies Testing and examination Procedures :IS 1993:2018 includes guidelines for slice, testing styles, and examination to corroborate compliance with quality and safety norms.

- obligatory for BIS certification Compliance :Manufacturers and importers must misbehave with IS 1993:2018 and gain BIS instrument to vend cold reduced electrolytic tinplate in the Indian request.

Why is BIS Certification Mandatory

BIS certification is mandatory for Cold Reduced Electrolytic Tinplate (CR ETP) under IS 1993:2018 to ensure that the product meets the quality, safety, and performance requirements established by the Bureau of Indian Standards (BIS). Electrolytic tinplate is widely used in critical applications such as food cans, beverage containers, closures, and packaging for chemicals and oils. Since these products often come into direct contact with consumable and sensitive materials, it is essential that the tinplate provides proper corrosion resistance, strength, and surface integrity. BIS certification ensures that the tinplate is manufactured using approved raw materials, controlled processes, and meets the specified coating thickness and mechanical properties.

Key Reasons:

- Ensures Product Quality and Safety :BIS certification confirms that cold reduced electrolytic tinplate meets the required quality, strength, and erosion resistance standards.

- Protects Consumer Health and Packaging Integrity :It ensures the tinplate is safe for packaging food, potables, and chemicals without threat of impurity or material failure.

- obligatory for Legal trade in India :Manufacturers and importers must gain BIS certification to fairly manufacture, import, or vend tinplate products in the Indian request.

- Verifies Compliance Through Testing and Inspection :BIS conducts product testing and plant examinations to insure harmonious manufacturing quality and compliance with IS 1993:2018.

- Prevents Substandard Products in the request :instrument helps exclude low- quality ornon-compliant products, icing trustability and maintaining assiduity norms.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Compliance with Indian Standard IS 1993:2018 :Ensures the tinplate meets specified conditions for chemical composition, coating mass, and mechanical parcels. | Ensures High Product Quality and trustability :certification guarantees harmonious performance, erosion resistance, and continuity of tinplate products. |

| obligatory BIS Standard Mark :certified products must carry the BIS Standard Mark, attesting compliance with public quality and safety norms. | Legal Authorization to Sell in India BIS certification allows manufacturers and importers to fairly request and distribute their products. |

| plant examination and Quality Control BIS verifies manufacturing installations, product processes, and quality control systems before granting instrument. | Builds client Trust and request Character The BIS mark increases client confidence in product quality and safety. |

| Testing in BIS- Recognized Laboratories Products must undergo testing for coating consistency, strength, face finish, and continuity as per BIS guidelines. | Reduces threat of Product Failure and Complaints :Ensures strict quality checks, minimizing blights, erosion, and packaging failures. |

| needed for Manufacturers and Importers :Both domestic manufacturers and foreign importers must gain BIS instrument to vend tinplate in India | Improves Market Access and Business openings :certified products are more respectable in government projects |

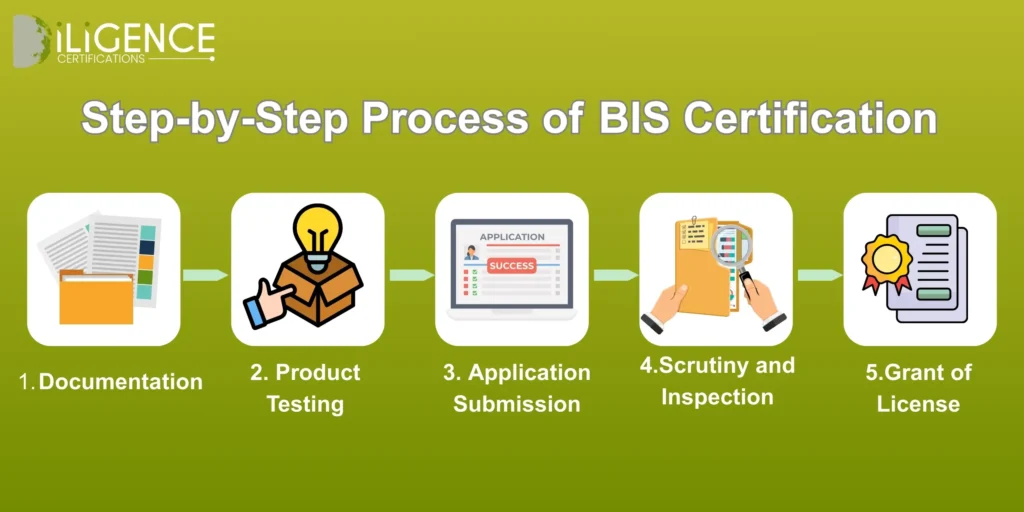

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications provides complete assistance for obtaining BIS Certification for Cold Reduced Electrolytic Tinplate under IS 1993:2018. With strong expertise in BIS regulations and compliance procedures, the company helps manufacturers and importers navigate the certification process smoothly and efficiently. Their team ensures proper documentation, coordination with BIS authorities, and guidance on product testing and factory inspection requirements. This reduces delays and helps clients achieve certification faster.Diligence Certifications offers end-to-end support, including application filing, technical documentation preparation, product testing coordination, and BIS liaison services. Their expert consultants help ensure that your product meets all quality and compliance requirements, minimizing the risk of rejection. They also provide regular updates and professional guidance throughout the certification process.

Conclusion

BIS Certification for Cold Reduced Electrolytic Tinplate under IS 1993:2018 is essential to ensure product quality, safety, and compliance with Indian standards. It confirms that the tinplate meets the required specifications for coating, strength, surface finish, and corrosion resistance, making it suitable for packaging and industrial applications. The certification process involves strict testing, inspection, and quality control measures to maintain consistency and reliability.

Frequently Asked Questions (FAQs)

What is IS 1993:2018?

IS 1993:2018 is the Indian Standard that specifies requirements for Cold Reduced Electrolytic Tinplate used in packaging and industrial applications.

Is BIS certification mandatory for electrolytic tinplate?

Yes, BIS certification is mandatory for manufacturers and importers to sell electrolytic tinplate in India.

What is Cold Reduced Electrolytic Tinplate (CR ETP)?

It is a thin cold-rolled steel sheet coated with tin to provide corrosion resistance and improved surface finish.

Who needs BIS certification under IS 1993:2018?

Both Indian manufacturers and foreign importers must obtain BIS certification for compliance.

What does the BIS Standard Mark indicate?

The BIS mark confirms that the product meets Indian quality, safety, and performance standards.

What tests are required for BIS certification?

Products are tested for coating thickness, mechanical properties, chemical composition, and surface quality.

Which industries use electrolytic tinplate?

It is widely used in food cans, beverage containers, closures, oil cans, and chemical packaging.

How long does it take to get BIS certification?

The process usually takes a few weeks to months, depending on documentation and testing compliance.

What happens if a product is sold without BIS certification?

Selling non-certified products can lead to legal penalties and restrictions in the Indian market.

Why is BIS certification important for manufacturers?

It ensures legal compliance, improves product credibility, and increases customer trust and market acceptance.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration