- Ensures Product Quality and Compliance: The BIS certification CORRUGATED ALUMINIUM SHEET based on IS 1254 ensures that the corrugated aluminum sheets are of Indian standards regarding quality, strength, durability, and performance.

- Mandatory for Market Approval in India: The BIS certification is mandatory for manufacturers to produce, sell, or distribute corrugated aluminum sheets in the Indian market.

- Covers Technical and Physical Requirements: The standard covers requirements like sheet thickness, size, mechanical properties, and tolerances to ensure consistency and reliability

- Includes Testing and Factory Inspection: The BIS performs product testing in accredited labs and factory inspections to check the manufacturing process and quality control systems.

- Builds Customer Trust and Market Credibility: The BIS certification of corrugated aluminum sheets helps build customer trust and market acceptance in the construction and industry sectors regarding safety and compliance.

Introduction

BIS Certification for Corrugated Aluminium Sheet IS 1254: The BIS Certification for Corrugated Aluminium Sheet IS 1254 is a certification that ensures the quality of the aluminium sheets used in the construction of roofs, cladding, and other structural purposes as per the standards laid down by the Bureau of Indian Standards (BIS). Corrugated aluminium sheets are used extensively in the construction of industrial buildings, warehouses, residential buildings, and other infrastructure projects.

What is IS 1254?

IS 1254 is an Indian Standard, which is published by the Bureau of Indian Standards (BIS), that outlines the requirements for corrugated aluminum sheets, mainly used for roofing, cladding, and general construction work. This standard is used to ensure that the sheets conform to certain quality, strength, and size parameters.

Key Points:

- Defines Material Specifications:IS 1254 specifies the type and grade of aluminium that should be used for the manufacture of corrugated sheets.

- Specifies Dimensions and Thickness:IS 1254 specifies the requirements for sheet thickness, width, length, corrugation, and tolerances.

- Ensures Mechanical Strength and Performance:IS 1254 specifies the minimum strength and performance requirements so that the sheets can resist environmental factors such as wind, rain, and weight.

- Includes Quality and Finish Requirements:IS 1254 specifies the correct surface finish, free from defects such as cracks, dents, and corrosion that may impair performance.

- Required for BIS Certification Compliance:Manufacturers are required to comply with IS 1254 to obtain BIS certification, which ensures that the corrugated aluminium sheets are of Indian quality and safety standards.

Why is BIS Certification Mandatory

BIS certification is required for corrugated aluminum sheets as per IS 1254 to ensure that the product satisfies the desired quality, safety, and performance standards as defined by the Bureau of Indian Standards. These sheets are commonly used in roofing and structural works, where the need for strength, durability, and corrosion resistance is of utmost importance. BIS certification ensures that only trustworthy products are available in the market.

Key Reasons:

- Ensures Product Quality and Safety:BIS certification ensures that the corrugated aluminum sheets are of required strength, durability, and safety standards for use in roofing and construction works.

- Prevents Use of Substandard Materials:It safeguards consumers and builders against the use of low-quality or defective aluminum sheets that may fail or corrode .

- Mandatory for Legal Manufacturing and Sale:BIS certification is mandatory for the legal manufacture, sale, or supply of corrugated aluminum sheets in India, where BIS is applicable.

- Confirms Compliance with Indian Standards:The certification confirms that the product complies with all the technical requirements as specified in IS 1254, including thickness, size, and performance.

- Builds Trust and Market Acceptance:BIS-certified products help build customer trust, enhance brand reputation, and are in high demand in government and infrastructure projects.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| IS 1254 Standard Compliance:The corrugated aluminum sheets should comply with all the technical specifications regarding thickness, size, corrugation, and quality of material as per IS 1254 Standard. | Ensures High Product Quality:The certification ensures that the quality of aluminium sheets is at par with the country’s standards. |

| BIS License for Using Standard Mark:The manufacturer needs to obtain a license from BIS to mark the corrugated aluminum sheets with the Standard Mark (ISI Mark) before marketing them in the Indian market. | Boosts Customer Trust and Confidence:The ISI mark on the product ensures that the customer is purchasing a safe and reliable product that is certified by BIS |

| Testing of Sheets in BIS-Recognized Labs:The sheets should be tested in BIS-recognized labs to check their mechanical strength and quality. | Increases Market Acceptability:BIS-certified products are accepted in all government projects and construction sectors. |

| Factory Inspection by BIS Authorities:The BIS authorities inspect the factories to check the manufacturing process and quality of material used. | Enhances Brand Reputation:The company’s brand reputation is enhanced as it starts supplying BIS-certified products. |

| Surveillance by BIS Authorities:The BIS authorities perform surveillance activities, including testing and inspection, to ensure that the sheets comply with IS 1254 Standard. | Facilitates Legal Compliance and Business Expansion:The certification will help the company comply with the Indian laws and regulations and expand its business in the Indian market. |

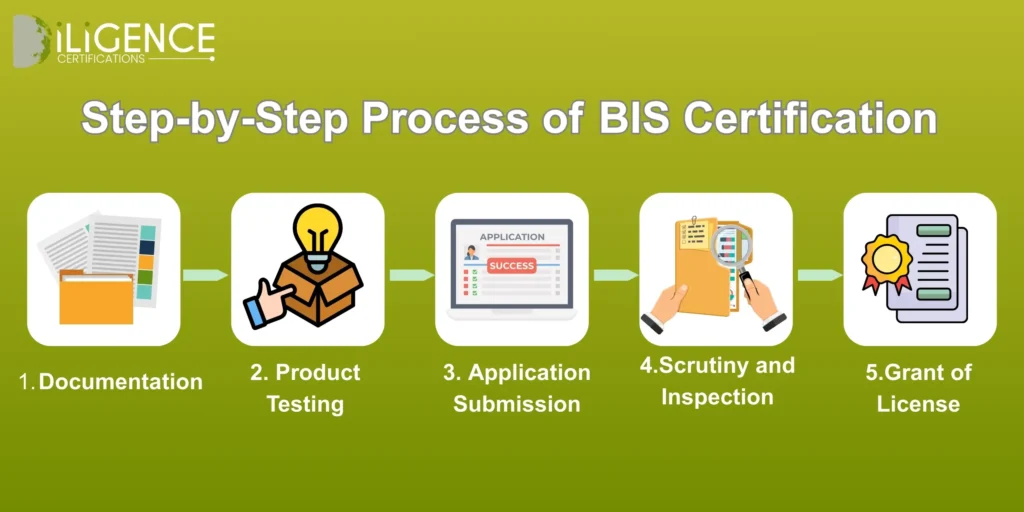

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications is a reliable consultancy service that offers end-to-end assistance for BIS certification of corrugated aluminum sheets as per IS 1254. At Diligence Certifications, professionals are well-versed with the BIS norms and procedures for certification and assist manufacturers in the entire process with ease and accuracy.

Conclusion

BIS Certification for Corrugated Aluminium Sheet as per IS 1254 is necessary to ensure that the product complies with the standards of quality, safety, and performance requirements as specified by the Bureau of Indian Standards. This certification ensures that the aluminium sheets are suitable for use in roofing, cladding, and construction.

Frequently Asked Questions (FAQs)

What is IS 1254?

IS 1254 is the Indian Standard that lays down the requirements for corrugated aluminium sheets used for roofing and cladding purposes.

What is BIS certification?

BIS certification is an assurance that the corrugated aluminium sheets are in conformity with the quality and safety standards of India.

Is BIS certification mandatory for corrugated aluminium sheets?

Yes, BIS certification is mandatory to ensure the quality of the corrugated aluminium sheets and their conformity with Indian standards, if any.

Who issues BIS certification?

The Bureau of Indian Standards (BIS), which is the national standards body of India, issues the certification.

What is the ISI mark?

The ISI mark is an indication that the product is certified by BIS and is in conformity with IS 1254.

Why is BIS certification important?

It ensures product safety, quality, durability, and customer trust.

How long does BIS certification take?

The process takes 4-8 weeks, depending on the documentation and testing.

Is product testing required for BIS certification?

Yes, testing in BIS-approved labs is mandatory.

Does BIS inspect the factory?

Yes, BIS inspects the factory to check the manufacturing and quality control processes.

Who needs BIS certification?

Manufacturers of corrugated aluminum sheets need BIS certification before they can sell their products in India.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration