- Mandatory Quality Standard IS 12171:2019 specifies quality conditions for cotton bales supplied for marketable and artificial use in India.

- Fiber & Contamination Control Ensures limits on trash content, humidity position, and foreign matter to maintain cotton chastity.

- Livery Quilting & Weight Defines standard overload weight, confines, and packing styles for thickness and easy running.

- Testing & Inspection Cotton bales must be tested and audited as per specified styles to corroborate compliance with the standard.

- Market & Export Acceptance BIS- certified cotton bales gain better acceptance in domestic and transnational requests due to assured quality.

Introduction

BIS Certification for Cotton Bales as per IS 12171:2019 ensures that cotton bales manufactured, packed, and supplied in India meet prescribed quality and safety standards. The standard focuses on fiber quality, impurity control, humidity content, and invariant packaging to maintain thickness and trustability. BIS instrument helps cover buyers, supports fair trade practices, and enhances the request value and adequacy of cotton bales in domestic as well as import requests.

What is IS 12171:2019?

IS 12171:2019 is an Indian Standard published by the Bureau of Indian Standards( BIS) that lays down comprehensive conditions for cotton bales used in marketable, artificial, and import operations. The standard is designed to insure invariant quality, chastity, and thickness of cotton bales produced and supplied across India, thereby guarding the interests of buyers, manufacturers, and dealers. The standard specifies detailed criteria related to cotton fiber quality, including limits on trash content, presence of foreign matter, and humidity chance. These parameters are essential to help impurity, deterioration during storehouse, and recycling issues in cloth manufacturing. By controlling humidity situations, IS 12171:2019 also helps reduce pitfalls similar to fungal growth, fiber damage, and weight manipulation.

Key Points:

- Quality Specification Standard IS 12171:2019 defines the quality conditions for cotton bales used for marketable, artificial, and import purposes.

- impurity & humidity Control It sets admissible limits for trash, foreign matter, and humidity content to insure cotton chastity and continuity.

- Formalized Overload Parameters The standard specifies invariant overload weight, size, and packing styles for safe running and transport.

- Testing & Inspection styles Provides guidelines for slice, examination, and testing to corroborate compliance with quality morals.

- Request trustability Compliance with IS 12171:2019 improves buyer confidence and acceptance in domestic and transnational requests.

Why is BIS Certification Mandatory

BIS certification is mandatory for cotton bales to ensure harmonious quality, safety, and fairness in the cotton trade across India. Cotton is a critical raw material for the cloth assiduity, and variations in quality, humidity, or impurity can directly impact yarn strength, recycling effectiveness, and finished fabric quality. obligatory BIS instrument ensures that cotton bales misbehave with IS 12171:2019 and meet prescribed quality marks. The certification helps the force of thinned, light, or defiled cotton bales in the request. By administering standardized testing, examination, and packaging conditions, BIS instrument safeguards buyers against illegal trade practices and quality controversies. It also promotes translucency and uniformity throughout the force chain.

Key Reasons:

- Assures consistent Quality Ensures cotton bales meet IS 12171:2019 quality parameters for fiber, humidity, and impurity.

- Prevents illegal Trade Practices Protects buyers from contamination, redundant humidity, light bales, and inferior cotton.

- Supports Textile Industry Efficiency Helps maintain invariant raw material quality for smooth processing in spinning and manufacturing.

- Enhances Market & Export Acceptance BIS- certified cotton bales gain advanced trust in domestic and transnational requests.

- Regulatory & Legal Compliance obligatory Certification ensures adherence to BIS regulations and avoids penalties or trade restrictions.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Quality Standardization Ensures invariant quality of cotton bales as per IS 12171:2019 across the force chain. | Advanced request Credibility Enhances trust and character among buyers and assiduity stakeholders. |

| Contamination Control Regulates limits on foreign matter, trash, and humidity to cover cotton chastity. | Advanced Acceptance in Exports Facilitates smoother entry into transnational requests with assured quality. |

| Buyer Protection Safeguards cloth manufacturers and dealers from unacceptable or thinned cotton. | Reduced Quality controversies Minimizes rejection, claims, and controversies due to standardized specifications. |

| Trade translucency Promotes fair trade practices through defined examination and testing procedures. | functional effectiveness Ensures harmonious raw material quality for better processing and productivity. |

| Regulatory Compliance Helps manufacturers misbehave with obligatory BIS norms and avoid legal issues. | Competitive Advantage BIS mark differentiates certified cotton bales from non-compliant product |

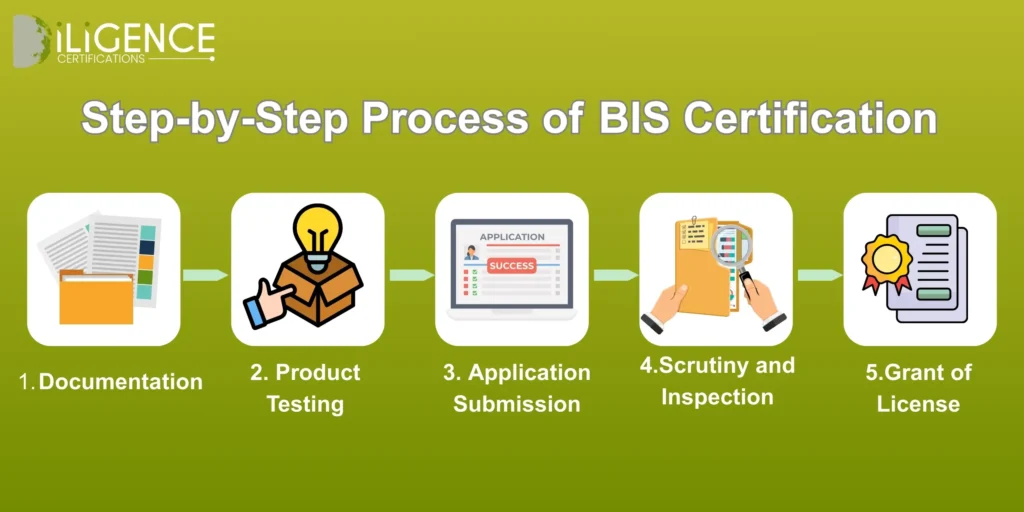

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications is a trusted compliance and certification consultancy committed to making nonsupervisory blessings simple, transparent, and stress-free for businesses. With strong moxie in BIS certification, CRS enrollment , and other Indian nonsupervisory fabrics, we guide manufacturers and importers through every stage of the instrument process — from attestation and product testing to final blessing. Our platoon focuses on delicacy, speed, and compliance, icing that your products meet all applicable Indian norms without detainments or complications. Diligence Certifications piecemeal is our customer- centric approach and deep understanding of evolving regulations.

Conclusion

BIS certification plays a pivotal part in icing product safety, quality, and nonsupervisory compliance in the Indian request. clinging to Indian norms helps cover consumers from implicit hazards while promoting thickness and trustability across products. carrying certification not only fulfills legal scores but also strengthens request credibility, builds consumer trust, and supports long- term business growth. By following the specified norms and instrument process, manufacturers and importers can ensure smooth request entry and sustained success in India.

Frequently Asked Questions (FAQs)

Is BIS certification mandatory for cotton bales in India?

Yes, BIS certification is mandatory to ensure quality and fair-trade compliance.

Which standard applies to cotton bales?

Cotton bales must misbehave with IS 12171:2019.

Who issues BIS certification for cotton bales?

The certification is issued by the Bureau of Indian Standards( BIS).

What does IS 12171:2019 cover?

It covers fiber quality, impurity limits, humidity content, overload weight, and quilting.

Is BIS certification needed for importing cotton bales?

Yes, it improves acceptance in both domestic and transnational requests.

Do cotton bales bear laboratory testing?

Yes, samples must be tested in a BIS- honored laboratory.

What's the validity of BIS certification?

Generally, the certification is valid for 2 times.

Can uncertified cotton bales be vended in India?

No, dealing uncertified cotton bales may lead to penalties and legal action.

How long does the BIS certification process take?

The process generally takes 20 – 30 days, depending on testing and attestation.

Is renewal needed after certification expiry?

Yes, BIS certification must be renewed before its expiration.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration