- Regulatory Compliance: BIS certification is a guarantee that the electrodes covered by the certification are compliant with the rigorous quality and safety standards outlined in IS 814:2004, thus providing legal and industry compliance to manufacturers and users. Covered Electrodes Of Manual Metal Welding

- Enhanced Welding Quality: Use of certified electrodes ensures the most stable arc, the deepest penetration, and the easiest slag removal with fewer defects resulting in increased structural strength of welded carbon and carbon-manganese steels.

- Market Credibility: BIS-certified electrodes manufacturers make it easier to attain clients and projects as their credibility gets enhanced, brand reputation improves and thus it becomes easier to supply to government and large industrial contracts.

- Safety Assurance: BIS-certified electrodes go through testing to ensure safe handling and performance under various welding conditions, thus eliminating the chances of accidents and subsequent structural failures during welding operations.

- Export and Industrial Advantage: BIS certification makes it easy for the company to be accepted in foreign markets and large projects where strict adherence to Indian Standards is a must and thus companies can expand their industrial and export footprint.

Introduction | Manual Metal Welding

In 2024, a middle-scale welding firm in Pune had a hard time securing government contracts as their applications were rejected several times even though they were making high-quality electrodes. The problem was not the performance of the product but the lack of a BIS certificate for Covered Electrodes of Manual Metal Welding under IS 814:2004. This situation is the main challenge of the welding industry in India which many manufacturers have to face. Getting a BIS certificate for Covered Electrodes of Manual Metal Welding under IS 814:2004 is not just a legal requirement. It is an indicator of quality, trust, and acceptance in the market. Certified electrodes mean that they are made in accordance with Indian Standards, thus the customers and contractors are given the assurance that the welding operations are done safely, efficiently, and without any defects. With this certification, the manufacturers will be the ones who will get the industrial contracts if they are competing against each other. The users, on the other hand, get a record of continuous arc stability, correct penetration, and safety standards being met. We, at this article, discuss what Covered Electrodes of Manual Metal Welding under IS 814:2004 means, the certification journey and the benefits in the real world with an industry expert viewpoint.

What is IS 814:2004?

IS 814:2004 is an Indian Standard defining the technical requirements for the used covered electrodes in the Manual Metal Arc (MMA) welding of carbon and carbon-manganese steel. The standard includes the identification of electrode types, chemical composition, mechanical properties, and performance criteria of welding to guarantee the quality, uniformity, and safety of the welding operations.

Key Points:

- The Scope of the standard: The standard covers electrodes for welding carbon and carbon-manganese steels.

- Electrode Classification: The types of electrodes are determined depending on the current, the coating, and the welding positions.

- Mechanical Requirements: The standard specifies the tensile strength, the impact value, and the elongation in order to make the welded joints structurally durable.

- Chemical Composition: The standard defines the percentage of elements like carbon, manganese, and sulfur giving the material the best performance.

- Welding Performance: The standard specifies requirements in this respect such as arc stability, slag removal, and bead appearance.

- Testing and Quality Assurance: The standard certification is accompanied by tests such as the bending, the tensile, and the impact tests that are compulsory for issuing the certificate.

- Safety and Reliability: The electrodes will be in perfect safety-working conditions under different welding conditions free from defects as per the standard.

Why is BIS Certification Mandatory?

In India, the Bureau of Indian Standards (BIS) is the national authority responsible for setting and enforcing quality standards across industries. For covered electrodes of manual metal welding under IS 814:2004, BIS certification is mandatory for several critical reasons:

Key Points

- Legal Compliance: It is a must as stated by the Indian law that the manufacturing and selling of electrodes should be done only after getting the legal permission.

- Quality Assurance: The electrodes are ensured to meet the standards in their chemical, mechanical, and welding performance.

- Safety & Reliability: The certified electrodes are those that have been tested for safe operation and performance.

- Market Credibility: It helps in establishing the trust with clients, contractors, government projects, etc.

- Industrial & Export Advantage: It becomes very easy to be accepted in large projects and international markets.

Importance and Benefits of BIS Certification

| Importance of BIS Certification | Benefits of BIS Certification |

| Legal compliance with Indian standards and regulations | Enables manufacturers to sell electrodes in local and government markets |

| Maintains electrode quality for safe and stable welding | Increases welding efficiency, and thus, the decrease of welding defects and failure of structures |

| Gives the guarantee that the buyers are free from the risk of inferior or dangerous products | Helps the brand to get more recognition and acceptance from the customers and contractors |

| Complying with national and international industrial standards | Making it easy to be involved in big projects and get export opportunities |

| Confirms the testing, performance, and safety of the electrodes | Helps in reducing the chances of legal action and enhancing the company’s market position |

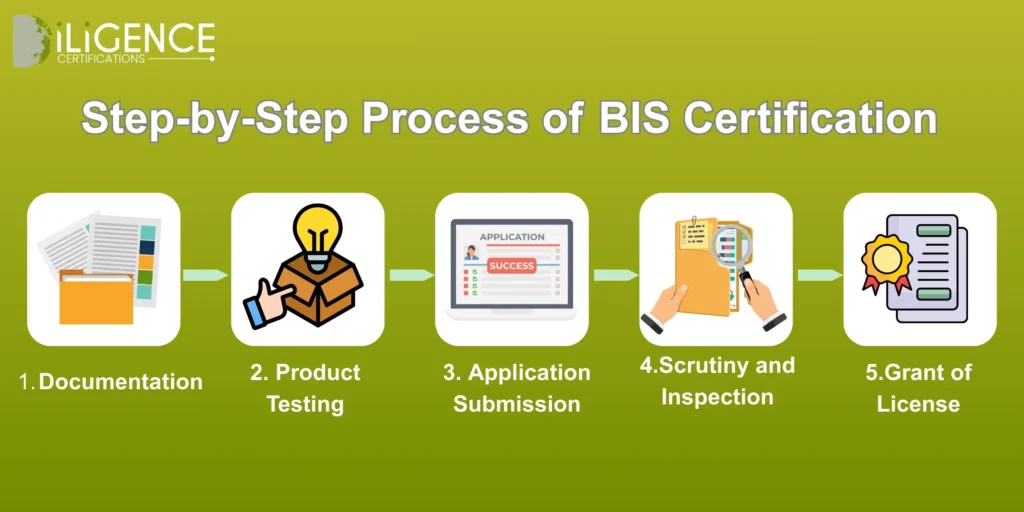

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- Expert Industry Knowledge: Diligence Certifications has deep industry knowledge and understands the technical details of IS 814:2004 very well as they have been in the welding and manufacturing sector for years. They can effectively guide manufacturers through compliance requirements.

- End-to-End Support: Diligence Certifications takes care of the entire process, from documentation, testing coordination, and application submission to the follow-up with BIS authorities, thus providing complete assistance to their clients and reducing their administrative burden.

- Proven Track Record: With the support of Diligence Certifications, a large number of SMEs and bigger manufacturers have been able to successfully acquire BIS certification, as a result, they can confidently apply for government contracts and industrial projects.

- Customized Solutions: Diligence Certifications recognizes that each factory has a unique setup and thus they provide personalized advice on the quality systems, electrode testing, and process improvements for certification to be approved smoothly.

- Time and Cost Efficiency: Diligence Certifications takes the certification process to the next level and thus avoids the most common mistakes giving businesses the opportunity to save both time and money and to be able to enter the market much faster with products that have been approved by BIS.

Conclusion

Getting a BIS certificate for Covered Electrodes of Manual Metal Welding under IS 814:2004 is not just a regulatory requirement but a strategic move that brings in quality, safety, and brand value in the welding industry, which is highly competitive. BIS certification is a seal of approval for electrodes that meet strict standards for their chemical, mechanical, and performance characteristics, thus giving manufacturers the needed market trust and customers a safe welding solution free from defects. It can be a hassle to complete the process by yourself but if you hire a certification consultant like Diligence Certifications, you can be sure that the process will be smooth, without delays, and that you will be in full compliance with IS 814:2004. For the manufacturers who want to scale up their industrial projects, get government contracts, or venture into exports, BIS certification is a must-have that will give you positive returns in terms of reputation, reliability, and business growth over time.

Frequently Asked Questions

What are Covered Electrodes of Manual Metal Welding under IS 814:2004?

Covered electrodes are consumables that are used in MMA welding of carbon as well as carbon-manganese steel, which conform to IS 814:2004 standards.

Why is BIS certification required for these electrodes?

The BIS certification is an assurance of conformity to IS 814:2004. So the products will be of good quality, safe, and legal to be sold in the market.

Who can apply for a BIS certification for these electrodes?

Manufacturers covered electrodes producing carbon or carbon-manganese steel welding consumables in India can apply for a BIS certificate.

What tests are done for BIS approval?

Tests such as chemical composition, tensile strength, bend, impact, and welding performance are conducted for approval.

How long does BIS certification take?

BIS certification usually takes around 2-4 months, depending on the availability of documents, testing, and BIS Inspection.

Are the electrodes with BIS certification allowed to be traded internationally?

Yes. BIS certification facilitates the acceptance of the product in the various foreign markets and large industrial projects.

Does BIS certification improve welding quality?

Definitely, electrodes that are certified are those which keep the arc stable, ensure good penetration, and welds without defects.

Is BIS certification obligatory for government projects?

Yes, the majority of the Indian government and industrial contracts make it a prerequisite that the electrodes used are compliant with IS 814:2004.

What documents are required for the BIS application?

Test reports, factory details, quality control records, company registration documents, and other such documents.

Why to Diligence Certifications for BIS approval?

These experts provide you with the proper guidance, support throughout the whole process, and facilitate the certification to get the approval on time.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration