- BIS Scheme X Certification is mandatory for manufacturers of embroidery machinery and their components in India.

- This certification ensures safety, quality, and regulatory compliance under the BIS (Bureau of Indian Standards).

- For domestic and imported embroidery equipment—manual, semi-automatic, or computerized—Scheme X helps manufacturers gain market trust.

- Compliance boosts both B2B and export credibility. Learn how Indian and global brands are navigating BIS certification

Introduction

In early 2024 a Surat based textile manufacturer purchased 2 computerized multi-head embroidery machines from a reputed Chinese company. The machines essentially cost over ₹18 lacs and the machines arrived at the Nhava Sheva port in perfect condition. But, the consignment was detained before the customs clearance due to a lack of a BIS Scheme X certification.

The client was completely unaware of what Scheme X even meant.

After a few weeks running from pillar-to-post talking to customs officers, DGFT officers and BIS consultants, the machinery was eventually seized and declared non-compliant. The factory lost over 60 days of production, export orders were missed and staff were close to being made redundant.This is not a unique situation.

As the Bureau of Indian Standards (BIS) ramp up their enforcement of the Scheme X certification, embroidery machinery manufacturers and importers and component manufacturers and importers are getting extremely reliant on compliance.

Through the lens of the newly adopted restrictions on the import of regional embroidery machines and accessories from all over the world (be it Tirupur based MSME for its EME domestic machines or from Gurugram importing ZSK and Tajima machines) it is time to embrace the future! It is downright important to understand the implications of the BIS Scheme X Certification!

What is BIS Scheme X Certification?

Scheme X is part of the Compulsory Registration Scheme (CRS) under the Bureau of Indian Standards. Unlike the traditional ISI mark (Scheme I), Scheme X specifically targets products that may impact public safety, performance, or environmental norms—most notably, electrical, electronic, and electromechanical products.

For machinery manufacturers, especially in textile automation and embroidery equipment, Scheme X ensures:

- Compliance with predefined Indian Standards (IS codes)

- Use of safe electrical and electronic components

- Approval through BIS-recognized test labs only

- Traceability and enforcement through a Registration Number (not ISI mark)

In short: it’s a regulatory gatekeeper that ensures only safe and BIS-approved machines are sold, imported, or installed across India.

This scheme aligns closely with India’s growing emphasis on Atmanirbhar Bharat, by curbing substandard imports and encouraging domestic quality improvement.

Scheme X is how India ensures that only technically compliant machinery enters the market. It’s not a formality—it’s a mandatory safeguard.

What Are Embroidery Machines and Their Main Components?

Embroidery machines are specialized textile machinery used for decorative needlework on fabrics. Embroidery machines can either be standalone machines or can be integrated with other industrial sewing systems.

Common types of embroidery machinery:

1. Computerized Embroidery Machines

2. Multi-Head Embroidery Machine

3. Single-Head Embroidery Machine

4. Chain Stitch Embroidery Machine

5. High-Speed Flat Embroidery Machines

6. Sequin Embroidery Machine

7. Laser Embroidery Cutting Machine

Each type of machine is suited for a particular type of production volume and design complexity. Computerized and multi-head machines are better suited for bulk production, while single-head machines cater to custom and small boutique orders.

Assemblies, Sub-Assemblies, and Components are inclusive of the following:

- Servo motors

- Drive modules

- Thread tension controllers

- Embroidery heads

- Needle bars

- Control panels

- Frame holders

- Stitching arms

- Computer control unit

- Wiring and circuit boards.

It is pertinent to note that a lot of these units/components are coming as separate parts and assembled in India; thus, the importance to compliance at the component level is justified.

Essential Certifications Required for Embroidery Machines

The Ministry of Textiles, in association with the Bureau of Indian Standards (BIS), has consolidated various textile machinery functional under mandatory certification including embroidery machine and its accessories.

Legal Mandate:

These machines are categorized under the Omnibus Technical Regulation (OTR) and require certification under the BIS Conformity Assessment Regulations, 2022. These are enforced as per the monitoring of BIS Scheme X, which deals with industrial machinery and electrical equipment.

Without this certification, no manufacturer or importer can sell or distribute embroidery machinery within India.

Certification ensures that these machines comply with the basic standards of safety, quality, and performance. This serves to protect the end user and corresponds to the efforts of the Government of India in promoting quality manufacturing in India, under the “Make in India” initiative.

Who needs this Certification?

Local manufacturers involved in the manufacturing of embroidery machines or their parts.

- Importers and traders who import machines from abroad.

- OEMs that source their component parts from other countries.

- Distributors and dealers who are engaged in the selling of embroidery machines within India.

If you fall under any of these categories, obtaining the BIS certification is mandatory, not optional. It enhances market credibility, avoids penalties, and provides easy operability in business.

Key Machinery Types Covered Under Scheme X

Embroidery machinery varies widely in complexity—from simple flatbed machines to fully automated, robotic systems. However, under BIS regulations, it’s not just the machinery that triggers certification—it’s the internal components.

Let’s break down the most common embroidery machines and their components that may fall under Scheme X compliance:

| Machine Type | Common Components | Scheme X Applies? |

|---|---|---|

| Flatbed Embroidery Machines | Stepper motors, power supplies | Yes |

| Multi-Head Automatic Units | Digital servo drives, PLCs, touch controllers | Yes |

| Cap/Tubular Embroidery Units | Encoder boards, switchgear | Yes |

| CNC Embroidery Machines | Integrated CNC controllers, linear motors | Yes |

| Laser-Embroidery Hybrids | Laser driver boards, motion ICs | Yes |

If even one core component in your embroidery system is listed under the CRS product categories (e.g. power adapters, controllers, motors), the entire machine may need BIS registration under Scheme X.

Examples of Covered Components:

- Power Supply Units (SMPS): Used to control voltage to electronic parts

- Servo Drives: Common in multi-head machines for precise needle control

- Controllers: Especially HMI or touch-screen panels from imported sources

- Motors: BLDC or stepper motors used for hoop rotation and fabric tensioning

- PLCs: Embedded controllers that handle logic automation

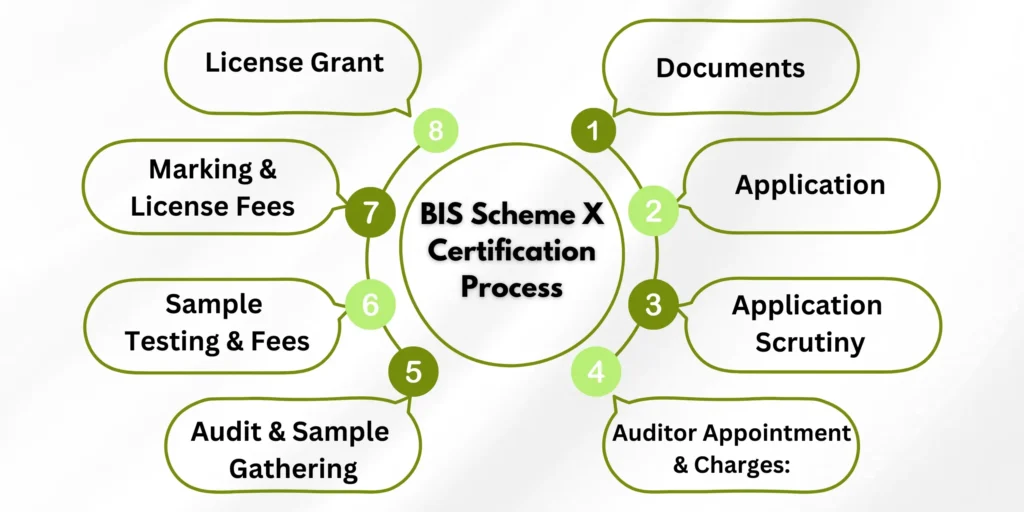

BIS Scheme X Certification Process for Embroidery Machinery

For most manufacturers and importers, the process sounds more complicated than it is. But a clear, step-by-step roadmap makes it manageable.

Here’s how to get your embroidery equipment BIS-certified under Scheme X:

1. Determine Applicability

- Check whether your machine or its components fall under the notified list on BIS.gov.in

- Focus on regulated electrical/electronic parts like controllers, drives, and PSUs

Many miss this stage and start testing non-mandated equipment, wasting weeks.

2. Identify BIS-Recognized Labs

- BIS only accepts reports from its empaneled labs

- Testing must be conducted in India, even for imported components

- Get technical drawings and component specs ready beforehand

3. Conduct Testing

- Submit sample units (machine or sub-component) for lab testing

- Labs perform checks against Indian Standards (IS codes)

- Testing can take 7–20 working days depending on queue

4. File Online Application on CRS Portal

- Use the BIS CRS portal for Scheme X registration

- Upload documents: lab test report, factory license, drawings, compliance forms

- Pay the BIS application fee based on equipment type

5. Await Factory Audit (if Required)

- For first-time applicants or system-level certifications, BIS may conduct a factory audit

- BIS officials verify batch control, labeling, and QMS systems

- Indian importers acting as OEMs must host audits if assembling locally

6. Grant of Registration

- If the application and audit are approved, BIS grants the Certification

This is not an ISI mark but is equally mandatory under Scheme X.

7. Renewal & Ongoing Compliance

- BIS registrations are typically valid for 2 years

- Renewal requires updated testing and application, even if model remains unchanged

- Any design change = re-application needed

Validity For BIS Scheme X Certification

Two years is the duration of the BIS scheme x certification, and re-verification/ compliance upgrading allows renewal.

Documents Required for BIS Scheme X Certification

- Product drawings and design documents

- Bill of materials (BOM)

- Factory license / Udyam Registration

- Test reports from BIS lab

- Brand Authorization letter (for foreign OEMs)

- Technical datasheet and user manual

- IEC code and GST certificate (for importers)

Accuracy and completeness in documentation are key to avoiding delays and rejections.

Key Benefits for BIS Scheme X Certification

- Market Access: The legal permissions granted to domestic as well as foreign manufacturers to enter the Indian market.

- Product Credibility: Safety, quality, and performance assurance creates consumer trust.

- Brand Reputation: Certified machines are favoured by institutional buyers as well as by exporters.

- Faster Customs Clearance: Import as well as export customs clearances are smoothened with compliance documentation.

- Business Growth: Providing for participation in government tenders and bulk contracts.

- Repeat Sales & Renewals: The renewal process is smooth, thus ensuring uninterrupted operations.

Conclusion

Navigating through the regulatory requirements pertaining to BIS Certification for Embroidery Machines and their components can certainly become complicated, but it matters. Products made to meet the BIS Scheme X certification halls carry high battlegrounds in terms of safety and quality standards for India’s growing textile industry.

Whether you’re a domestic manufacturer or an international importer, timely certification not only ensures legal compliance but also opens doors to wider business opportunities.

With expert partners like Diligence Certifications, the entire certification journey—from product testing to documentation and license approval—becomes smooth, reliable, and error-free. Their end-to-end support helps businesses save time, reduce costs, and enter the Indian market with confidence.

Diligence Certifications your trusted and reliable BIS partner.

Getting BIS certification can be complex, especially for small manufacturers or importers with limited compliance knowledge. That’s where Diligence Certifications comes in.

How Diligence Certification helps:

- Product classification under BIS Scheme X

- Laboratory coordination for product testing

- Preparing and reviewing documents

- Management of the online submission portal and filing of BIS Application

- Act as an AIR for foreign brands

- Label design assessment for regulatory compliance

- Renewals and all support services associated with BIS

Whether you are a domestic manufacturer installing an embroidery machine line or an importer sourcing components from abroad, Diligence Certifications can help you achieve your BIS requirements quickly, without delays and rejections!

Frequently Asked Questions

What is BIS Scheme X Certification for Embroidery Machinery?

BIS Scheme X Certification indicates that embroidery machines and components conform to Indian quality and safety standards. It is a certification mandatory under the Bureau of Indian Standards (BIS) and ensures product quality and consumer safety.

Which types of embroidery machines are required for BIS Scheme X Certification?

BIS Scheme X is applicable to all classes of embroidery machinery, such as:

Computerized Embroidery

Multi-head Embroidery

Single-head Embroidery

Industrial Embroidery

Various Embroidery Accessories (motors, frames, needles, etc.)

Why is Scheme X Certification important for embroidery machinery manufacturers?

Any manufacturer who intends to sell embroidery machines in India must obtain this certification for:

Quality and durability assurance of the product

Market entry compliance required by the government

Building consumer trust and brand reputation

Avoiding litigation for non-compliance

Who needs to apply for BIS Scheme X Certification?

The companies listed below should necessarily apply:

All manufacturers of embroidery machines-both domestic and international;

Importers who bring embroidery machines in India;

Suppliers and distributors involved in any of the following items: supply and distribution of embroidery equipment.

What is the process for Obtaining BIS Scheme X Certification?

The entire process of certification can be summed up as:

Application Submission – Register with BIS; submit all necessary documentation.

Product Testing – Machines are assessed in a BIS-approved laboratory.

Factory Inspection – Verify the manufacturing facility by BIS officials.

Certification Approval – Upon compliance, BIS grants the license.

Marking & Labeling – Apply the BIS Standard Mark to certified products.

How long does it take to get BIS Scheme X Certification?

The process for certification runs for about 4-6 weeks, the timing of which depends on the testing and inspection timelines. Certain delays may occur due to non-conformance or documentation errors.

How Does BIS Certification Scheme X Help for Global Trade?

Greater credibility is given to an existing manufacturer with BIS certification:

To facilitate exports to regulated markets

To encourage trust worldwide

For the winning of government and private tenders

Where Can I Apply For BIS Scheme X Certification for Embroidery Machinery?

You can apply directly to the Bureau of Indian Standards(BIS) or consult with Diligence Certifications for expert assistance.

How Can Diligence Certifications Help in Obtaining BIS ?

Diligence Certifications offer end-to-end support in the following arenas of work:

Document support

Coordination for product testing

Factory inspection guidance

Compliance consultancy

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration