- Mandatory Quality Compliance Ensures high tensile sword bars meet BIS norms for strength, continuity, and trustability in prestressed concrete operations.

- Mechanical Property Conditions Specifies tensile strength, yield strength, extension, and stress characteristics for safe structural performance.

- Material and Manufacturing norms Covers chemical composition, heat treatment, and manufacturing processes to insure harmonious product quality.

- Testing and examination Requires rigorous testing similar as tensile tests, bend tests, and dimensional checks to corroborate compliance with IS 2090:1983.

- BIS certification and Marking certified products can carry the BIS Standard Mark, attesting conformity and felicity for use in construction systems.

Introduction

BIS Certification for High Tensile Steel Bars for Prestressed Concrete as per IS 2090:1983, ensures that steel bars fitted in prestressed concrete structures are of quality, strong, and safe. These bars help in increasing the capacity, durability, and structural stability of bridges, buildings, flyovers, and other construction works. The standard sets the requirements for the chemical composition and mechanical properties of the steel bars, manufacturing methods, and testing to ensure good performance, consistent. BIS certification is the proof that the steel bars meet the Indian quality standards and are safe and reliable to use in construction works, especially in the critical ones.

What is IS 2090:1983?

BIS certification for High Tensile Steel Bars for Prestressed Concrete under IS 2090:1983 is a quality assurance process that ensures steel bars used in prestressed concrete operations meet the safety, strength, and performance conditions specified by the Bureau of Indian standards( BIS). These high tensile sword bars play a pivotal part in prestressed concrete structures by furnishing the necessary tensile strength to offset compressive forces, thereby enhancing structural stability, cargo- bearing capacity, and continuity. The standard applies to sword bars used in critical structures similar to islands, flyovers, road slumberers, transmission poles, artificial structures, and high- rise structures.

Key Points:

- Ensures high tensile sword bars meet BIS conditions for strength, continuity, and safe use in prestressed concrete structures.

- Specifies chemical composition and mechanical parcels similar as tensile strength, evidence stress, and extension.

- Covers manufacturing processes, heat treatment, face finish, and dimensional forbearance for harmonious quality.

- authorizations testing and examination, including tensile and bend tests, to corroborate compliance with IS 2090:1983.

- Allows certified products to bear the BIS Standard Mark, attesting conformity and acceptance in construction systems.

Why is BIS Certification Mandatory

BIS certification is mandatory for High Tensile Steel Bars used in prestressed concrete to ensure they meet the needed safety, strength, and quality standards defined under IS 2090:1983. These steel bars are used in critical structures similar as islands, structures, road slumberers, and transmission poles, where structural failure can lead to serious safety pitfalls and fiscal losses. BIS certification ensures that the sword bars are manufactured using approved raw materials , proper product processes, and strict quality control measures.

Key Reasons:

- Ensures Structural Safety Confirms that sword bars have the needed strength and trustability for use in critical prestressed concrete structures.

- Quality Assurance Verifies compliance with specified chemical composition, mechanical parcels, and manufacturing standards.

- Mandatory Regulatory Compliance needed to meet Indian construction regulations and BIS standards for legal manufacture and force.

- Prevents Substandard Products Helps exclude low- quality or unsafe sword bars from the request, icing harmonious performance.

- Builds Trust and Acceptance BIS- certified products are extensively accepted in government and private construction systems, enhancing credibility.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures Structural Integrity Confirms the sword bars can repel high stress and loads in prestressed concrete structures. | Market Acceptance BIS- certified products are preferred in government and private construction systems. |

| Maintains Formalized Quality Ensures invariant chemical composition, strength, and manufacturing quality across all certified products. | Quality Assurance Certification confirms the product has passed strict testing and examination procedures. |

| Supports Construction Safety Reduces the threat of structural failure in critical structures like islands and structures. | Enhanced Brand Character Improves manufacturer credibility and client confidence in product quality. |

| Regulatory Compliance Helps manufacturers misbehave with Indian norms and legal conditions set by BIS. | Reduced threat and Liability Minimizes chances of structural blights and affiliated safety issues. |

| Promotes Assiduity trustability Establishes trust among masterminds, contractors, and design authorities. | Competitive Advantage Helps manufacturers gain better openings in domestic and structure systems. |

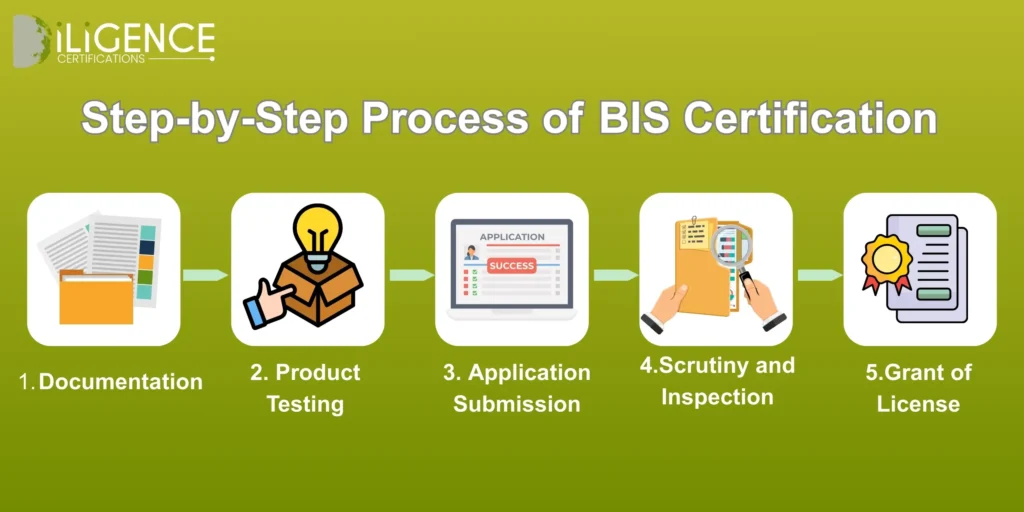

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certification is a trusted consultancy specializing in BIS Certification services for a wide range of products, including high tensile sword bars under IS 2090:1983. With expansive assistance experience and in- depth knowledge of BIS regulations, Diligence Certification provides complete support throughout the certification process, from attestation and operation form to testing collaboration and final blessing. Their expert platoon ensures that manufacturers meet all BIS conditions efficiently, reducing detainments and simplifying complex compliance procedures.

Conclusion

BIS certification for High Tensile Steel Bars for Prestressed Concrete under IS 20901983 plays a vital part in icing the safety, strength, and trustability of construction accoutrements used in critical structure. The instrument confirms that the sword bars meet strict conditions for chemical composition, mechanical parcels, manufacturing quality, and testing norms set by the Bureau of Indian standards. This helps insure harmonious performance and long- term continuity in prestressed concrete structures similar as islands, structures, and artificial systems.

Frequently Asked Questions (FAQs)

What's IS 2090:1983?

It's an Indian Standard that specifies quality and safety conditions for high tensile sword bars used in prestressed concrete.

Is BIS certification obligatory for high tensile steel bars?

Yes, BIS certification ensures compliance with Indian safety and quality standards for construction use.

Who issues BIS certification?

The Bureau of Indian Standards( BIS), the public standards body of India, issues the certification.

Why is BIS certification important for steel bars?

It ensures the steel bars are strong, durable, safe, and suitable for prestressed concrete structures.

What tests are needed for BIS certification?

Tests include tensile strength test, bend test, extension test, and dimensional verification.

What's the validity of BIS certification?

BIS certification is generally valid for 2 times and must be renewed before expiry.

Can manufacturers use the BIS Standard Mark after certification?

Yes, certified products can carry the BIS Standard Mark to show compliance.

Which products are covered under IS 2090:1983?

High tensile sword bars used in prestressed concrete structures like islands, poles, and structures.

Do foreign manufacturers need BIS certification?

Yes, foreign manufacturers must gain BIS certification and appoint an Authorized Indian Representative( AIR).

How long does the BIS certification process take?

The process generally takes 20 to 30 days, depending on testing and document blessing.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration