- Quality Compliance with BIS standards :BIS certification ensures that steel used for spring washers meets the quality conditions specified under IS 4072:1975 Steel for Spring Washers, icing strength, continuity, and dependable performance.

- Specified Chemical Composition :The standard defines precise limits for carbon, manganese, and other alloying rudiments to ensure the steel has the needed hardness, pliantness, and fatigue resistance.

- Mechanical Property Conditions :IS 4072:1975 specifies essential mechanical parcels similar to tensile strength, hardness, and adaptability, icing spring washers maintain proper pressure and locking capability.

- Heat Treatment and Manufacturing Control :The certification ensures that the sword undergoes proper heat treatment processes like hardening and tempering to achieve the asked spring action and performance.

- Testing and Inspection Assurance :BIS certification requires strict testing and examination procedures, including mechanical tests and quality checks, to ensure the sword is safe, dependable, and suitable for manufacturing spring washers.

Introduction

BIS Certification for Steel for Spring Washers under IS 4072:1975 ensures that the steel used in manufacturing spring washers meets the quality, strength, and performance requirements specified by the Bureau of Indian Standards (BIS). Spring washers are essential fastening components used to prevent loosening due to vibration, shock, or dynamic loads in mechanical and structural applications. The standard defines requirements for chemical composition, mechanical properties, heat treatment, and testing to ensure the steel provides proper elasticity and durability.

What is IS 4072:1975?

IS 4072:1975 is an Indian Standard issued by the Bureau of Indian Standards( BIS) that specifies the conditions for steel used in the manufacturing of spring washers. This standard ensures that the sword has the necessary strength, pliantness, hardness, and continuity needed for proper spring washer performance in fastening applications.The standard covers important aspects similar as chemical composition, mechanical parcels, heat treatment, manufacturing process, and testing styles. These conditions ensure that the steel can repel repeated stress, vibration, and cargo without losing its spring action or structural integrity.

Key Points:

- Indian Standard for Spring Washer Steel :IS 4072:1975 is a standard issued by the Bureau of Indian Standards( BIS) that specifies conditions for steel used in manufacturing spring washers.

- Defines Chemical Composition :The standard specifies limits for carbon, manganese, and other rudiments to insure proper hardness, strength, and pliantness of the steel.

- Specifies Mechanical parcels :It sets conditions for mechanical parcels similar as tensile strength, hardness, and adaptability to insure dependable spring washer performance.

- Covers Heat Treatment Conditions :IS 4072:1975 includes guidelines for heat treatment processes like hardening and tempering to achieve proper spring action and continuity.

- Ensures Quality and Testing Compliance :The standard requires proper testing, examination, and quality control to ensure the steel is safe, durable, and suitable for spring washer manufacturing.

Why is BIS Certification Mandatory

BIS Certification is a must to ensure that the quality, safety, and performance requirements of steel used for manufacturing spring washers conform to the standard specifications outlined in the code, i.e., IS 4072: 1975. Spring washers hold a significant place in the prevention of loosening of fasteners due to vibration, shock, and dynamic loads. If low-grade steel or steel with poor specs is used for manufacturing spring washers, it can result in washer failures.

Key Reasons:

- Guarantees the quality and reliability of products.:BIS certification ensures the steel meets the IS 4072:1975 standards for strength, elasticity, and durability for spring washer performance.

- Enhances safety in applications:Certified steel reduces the risk of washer failure, preventing loosening of fasteners and ensuring safety in automotive, machinery, and structural uses.

- Compliance with Indian Regulations:The certification through BIS is very well required for adhering to national quality standards and enables the manufacturer to use the ISI mark on their products.

- Ensures proper manufacturing and testing of the product. It ascertains that the heat treatment and quality control measures, including proper testing and inspection, are followed by the manufacturer with approved processes. It strengthens customer trust and ensures market acceptance.

- The BIS-certified steel brings more confidence to the customers, enhances product credibility, and ultimately assists the manufacturers to get wider acceptance in both domestic and industrial markets.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures Standardized Quality:BIS certification also ensures steel of defined quality for strength, elasticity, and durability, as required for the manufacture of spring washers. | Improved Product Reliability:There is better performance and durability along with good long-term life with certified steel. |

| Supports Safe Fastening Applications:Certified steel assists in the proper tensioning of spring washers and ensures that nuts and bolts do not loosen. | Increases Customer Confidence:Moreover, the ISI mark guarantees that the quality and safety standards within the country are met. |

| Maintains consistent manufacturing:It ensures that products are manufactured using the right techniques, heat treatment, and quality control to provide consistency in the products. | Enhances Market Opportunities:BIS certification enables manufacturers to gain access to more markets, both government and industry. |

| Prevents Use of Substandard Materials BIS certification will ensure that industries do not use low-quality steel material, as it can get damaged under vibrations and stress | Reduces Risk of Product Failure Proper testing and certification also minimize the possibilities of mechanical and maintenance troubles. |

| Ensures Regulatory Compliance It also helps to ensure that Indian standards and legislation for supplying industrial components with steel are met by manufacturers. | Strengthens Brand Reputation BIS certification helps in enhancing the credibility of a company. |

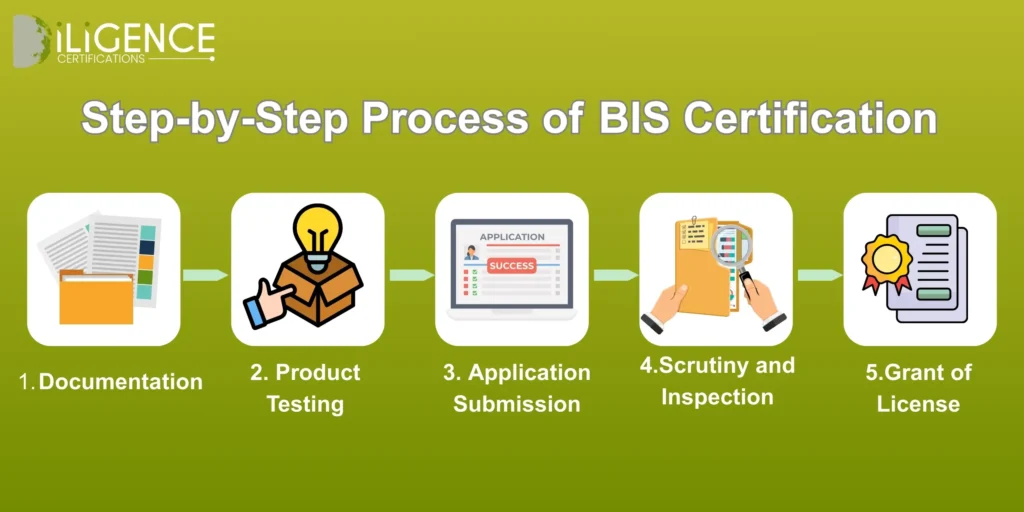

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications is a trusted consultancy that provides full support for BIS certification under IS 4072:1975 relating to springs used in steel washers. With vast experience in handling BIS compliance of steel and industrial products, Diligence Certifications helps manufacturers sail through the entire certification process with much ease and efficiency. Their expert team comprehends regulations, documentation, and the testing-related guidelines of BIS, hence ensuring accuracy and timeliness in the submission of applications.

Conclusion

BIS Certification of Steel Used in Steel for Spring Washers as Per IS 4072:1975 plays an important role in ensuring the quality, strength, and reliability of steel used. Steel for spring washers requires a BIS certification, as it guarantees that the required chemical composition, mechanical properties, and heat treatment standards of steel have been achieved, making it suitable for proper functioning, thus preventing fasteners from loosening.

Frequently Asked Questions (FAQs)

What is IS 4072:1975?

It is an Indian Standard that gives the requirements for the steel to be used in the manufacture of spring washers.

Who grants BIS certification?

BIS certification falls under the Bureau of Indian Standards, which is the national standards body of India.

Why is BIS certification necessary for spring washer steel?

It ensures the quality, strength, and safety of the steel to act in any performance related to fastening.

What does the BIS certification verify?

It checks the chemical composition, mechanical properties, heat treatment, and the quality of the product in general.

What is the ISI mark?

ISI mark signifies that the product meets the standards laid down by BIS and is certified for quality and safety.

Who needs BIS Certification under IS 4072:1975?

Organizations whose products, like the steel used for making spring washers, require BIS certification include manufacturers.

What tests are required in certification?

Tests include chemical analysis, tensile strength, and hardness, among other quality tests.

Is BIS certification mandatory in India?

Yes, it is compulsory or mandatory for the products covered by BIS directives to ensure safety

What are the advantages of BIS certification?

It enhances product quality, trust, and compliance with the law.

What is the period of BIS certification valid for?

BIS Certification remains valid for a particular period of time, which has to be renewed accordingly.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration