- Mandatory BIS Certification under the latest QCO notifications.

- It covers motors, generators, alternators, and rotary transformers.

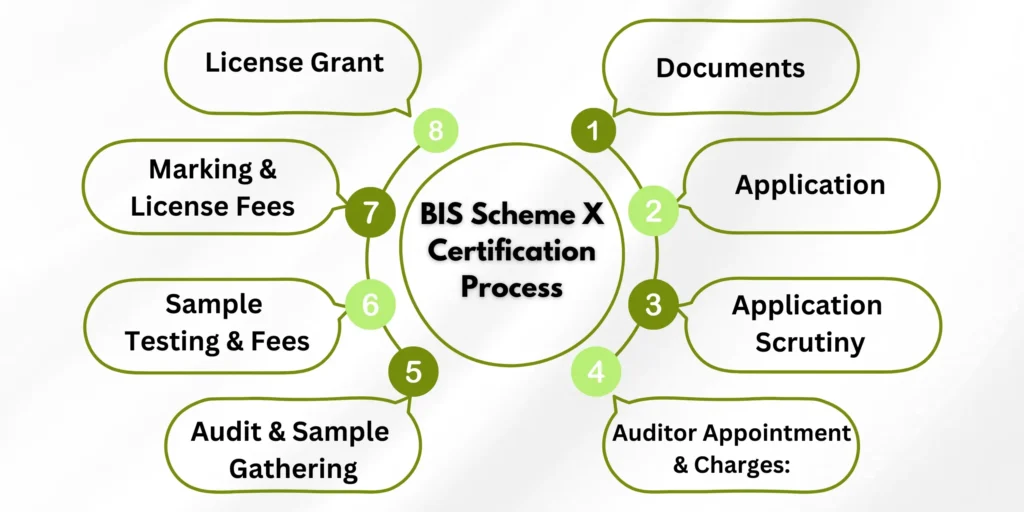

- The process falls under BIS Scheme X; no factory audit is required.

- Certification is based on lab testing and technical documentation.

- It ensures electrical safety, efficiency, and compliance.

- Manufacturers, importers, and rebranders need this certification.

- The certificate is valid for one year and can be renewed annually.

- Not complying can lead to fines, seizure, or legal penalties.

- It boosts market trust and eligibility for government tenders.

- Applications are made through the Manakonline portal, the official BIS site.

Introduction

As India strengthens its quality control framework for electrical equipment, rotary electrical machines like motors and generators have come under the radar of mandatory BIS certification. If you’re a manufacturer or importer of rotary machines, this guide is for you

As per the updated scheme on certification by Bureau of Indian Standards (BIS), the mentioned electrical machines include electrical motors, generators, alternators, and other types of rotating equipment that function in different industries.

Power Plants, manufacturing units, and the transport industry depend on these rotary electrical machines for the generation of power. The Bureau of Indian Standards has endorsed their certification for these products under Scheme X to maintain the quality and reliability of functioning.

The blog will serve as a complete guide on BIS certification for rotary electrical machines, types of certification in it, standards under which it will be covered, compliance requirements for it, and benefits to manufacturers and importers.

The BIS certification is for rotary electrical devices, which ascertains that the products conform to the Indian safety and performance standards that aid the manufacturers in ensuring customer trust and acceptance from the regulatory authorities.

Types of Rotary Electrical Machines Covered Under BIS Certification

The BIS certification applies to a variety of rotary electrical machines, among which are:

- Generator: The machines known as generators perform the conversion of mechanical energy into electrical energy.

- Electric Motor: The machine, called an Electric Motor, does this conversion in the reverse way and converts electrical energy into mechanical energy.

- Alternators are specialized types of generators that produce alternating current (AC).

- Rotary Converters: Rotary Converters are devices for converting in either direction.

- Sub-Assemblies & Components include stators, rotors, windings, insulation materials, and other important parts of rotary machines.

They are widely used in:

- Manufacturing plants

- Consumer appliances

- Automotive systems

- Energy generation

Importance of BIS Certification for Rotary Electrical Machines

There are many electrical products, the BIS certification of which proves their conformity to Indian standards. The major features are:

- Quality Assurance: Ensure overall reliability and efficiency of electrical machines.

- Consumer Safety: Protects users against electrical hazards and malfunctions.

- Market Acceptance: Qualifies the product for sale in India through by regulated market

- Legal Compliance: Saves manufacturers from penalties and controversies of irrelevant compliance.

- Brand Credibility: To create customer trust along with a competitive advantage in the industry.

- Environmental Compliance: Compliance with energy efficiency and environmental regulations is ensured for rotary machines.

- Increased Export Opportunities: Envisions facilitation of international trade by aligning itself towards global quality standards

5 Powerful BIS Certification Process for Rotary Electrical Machines

Here are some steps or outlines on how such manufacturers can be certified:

1. Identify the Applicable BIS Standard

Such manufacturers have to ascertain that the IS standard is relevant to the rotary electrical machines employed. Some of the common standards include:

- IS 4722: Specification for rotating electrical machines.

- IS 325: Specification for three-phase induction motors.

- IS 13364: Specification for alternators used for power generation.

- IS 9000: Environmental testing requirements for electrical equipment.

2. Application

Application submission is done using the BIS online portal and must include other relevant documents such as:

- Details of the manufacturing unit

- Specifications and test reports/reference documents for the product

- Factory layout with process flow

- Quality control measures adopted

- Calibrated certificates of testing equipment

- Details of safety and environmental compliance.

3. Product Testing at a BIS-recognized Laboratory

The test at a BIS-accredited lab shall be mandatory for all products in the course of which their adherence to safety, efficiency, and performance standards should be verified.

4. Factory Inspection

On-site inspection of the manufacturing facility by BIS officials for quality control procedures implemented, testing equipment available, and production capabilities.

5. Grant BIS Certification

Certification will be granted by BIS after fulfilling all the aspects making it possible for manufacturers to stamp ISI on Rotary Electrical Machines.

Documents Required for BIS Certification

To facilitate the certification process, the manufacturers are expected to furnish the requisite documents:

- Business registration certificate

- Plant details

- Test reports from BIS-approved testing laboratories

- Quality control documents

- Authorized Indian Representative (AIR) details in the case of foreign manufacturers

- Bill of materials (BOM) and drawings of the product

- Energy-performance compliance reports, wherever applicable

Cost of BIS Certification

BIS certification costs can vary based on the type of rotary electrical machine, the testing it requires, and the applicable BIS scheme. The main cost components include:

- Application fees

- Testing charges

- Inspection fees

- License fee upon approval

- Renewal and maintenance fees

Why BIS Certification is Required

Under BIS Scheme X, certain rotary machines must meet Indian Standards (IS) to ensure:

- Product safety.

- Performance efficiency.

- Environmental compliance.

- Quality assurance for domestic and export use.

Uncertified products may be banned from sale or rejected by regulatory bodies and government tenders.

Why BIS Certification is Required

BIS (Bureau of Indian Standards) is the national authority that sets product standards in India. Certification under Scheme X ensures products are:

- Technically compliant with Indian Standards

- Safe for public and industrial use

- Eligible for import, sale, and government tenders

- Traceable in case of manufacturing faults or failures

For rotary machines, failure to certify may lead to:

- Legal penalties under the BIS Act

- Product rejection at customs

- Ineligibility for B2B contracts or bulk sales

- Loss of credibility and brand trust

Types of Rotary Electrical Machines

Rotary electrical machines are devices that convert electrical energy into mechanical energy and vice versa. They are mainly of three types:

- DC Machines – DC motors and DC generators.

- AC Machines – Alternators, Induction motors, and Synchronous motors.

- Special Purpose Machines – Stepper motors, Servo motors, BLDC, PMSM, and Universal motors.

For safety, quality, and performance, manufacturers need BIS Certification for Rotary Electrical Machines. The Bureau of Indian Standards (BIS) regulates this, and products not under mandatory certification can obtain approval through BIS Scheme X certification.

Step-by-Step BIS Scheme X Certification Process

Step 1: Identify Product Standard (IS Code)

Determine the exact IS (Indian Standard) applicable to your machine model:

- Voltage rating

- Type (AC/DC/Universal)

- Use case (consumer, industrial)

Step 2: Register on Manakonline Portal

Visit https://www.manakonline.in

Create a manufacturer account and begin your application under Scheme X – CRS (Conformity Assessment Scheme).

Step 3: Prepare Documentation

You’ll need the following documents:

- PAN, GST, Company Registration

- Factory License and ISO 9001 Certificate

- Detailed Technical Sheet (specs, materials, power rating)

- Quality Control Plan (QCP)

- Internal Test Report (if any)

- Previous certifications (if applicable)

Step 4: Submit Product Sample to BIS Lab

Choose a BIS-recognized laboratory for the relevant IS standard. Send product samples and await test results.

Common tests include:

- Dielectric strength

- Insulation resistance

- Efficiency and torque measurement

- Rise in temperature

- Endurance and operational safety

Test reports are valid only if issued by a BIS-accredited lab.

Step 5: Factory Audit by BIS Officers

A team from BIS will:

- Inspect your manufacturing unit

- Review test setups, calibration records

- Verify employee qualifications

- Assess raw material and process traceability

The audit ensures that products will consistently meet standard requirements.

Step 6: Grant of BIS Certification

After successful evaluation of:

- Product test reports

- Factory inspection

- Documentation

You’ll be issued a BIS License Number (CM/L) and allowed to affix the ISI mark on the certified models.

Step 7: Post-Certification Obligations

- Maintain daily production and test logs

- Cooperate with BIS surveillance visits

- Renew your certification periodically

- Report changes in design, process, or plant location

Documents Checklist for BIS Scheme X Certification

| Required Document | Purpose |

|---|---|

| Company Registration (GST, CIN, PAN) | Legal proof of entity |

| Factory License & ISO Certification | Operational compliance |

| Product Technical File | Details on design, components, specs |

| Internal Quality Manual | Quality assurance processes |

| Authorization Letter (for agent filing) | If applying through consultant |

| Sample Lab Test Reports | Compliance verification |

Role of Authorized Indian Representative (AIR) for Foreign Manufacturers

Foreign manufacturers intending to obtain BIS certification should appoint an appropriately empowered Authorized Indian Representative (AIR). This AIR acts as a communication channel for the foreign manufacturer with BIS, and facilitates compliance and acquisition of certification.

The following are the typical responsibilities for an AIR:

- Coordinate with BIS for testing and inspections.

- Documentation and regulatory formalities

- Handle post certification compliance and product labeling.

Renewal and Maintenance of BIS Certification

The certification process is not a one-time event, as per the BIS. Manufacturer compliance is required over a while. Renewal must consist of the following steps:

1. Periodic surveillance audits by BIS officers.

2. Submission of new test reports.

3. Renewal of the certificate after the validity period, usually between 1-2 years.

Why Choose Diligence Certification for BIS Registration?

Diligence Certification offers expert services to companies on BIS compliance. It makes certification as easy as possible for rotary electrical machines and components. The list of services includes –

- Specialized consultations on BIS requirements

- Product test facilitation and documentation

- Factory audit aid

- BIS application and approvals processing

- AIR services for foreign manufacturers

Diligence certification offers consulting that helps manufacturers quickly streamline the BIS certification process while maintaining regulatory compliance in their businesses.

Benefits of Obtaining BIS Certification

- Legal Entry into the Market – For selling rotating electric machines in India, BIS certification is mandatory as per the government rules regarding it.

- Quality Assurance – Certified products are made to comply with heavy safety and performance standards that minimize the possibility of electrical failures or accidents.

- Competitive Advantage – The trust and preference of customers are developed for such certified products in contrast to uncertified varieties.

- Export Opportunities – Many foreign markets recognize the BIS certification and provide uncomplicated positioning in the international trade realm, along with enhanced export potential for the products concerned.

- Government Recognition – BIS certification gives products official recognition, thereby easing the tendering process in government contracts and bulk supply.

- Enhanced Reputation of Brand – The trust mainly develops for the brand and also shows that the brand is committed to quality and reliability.

- Consumer Safety and Satisfaction – This guarantees that quality, durability, and safe operation will reach the end consumers.

Conclusion

The BIS certification of rotary electrical machines is much needed to ensure product safety, quality, and market acceptability in India. Rating of generators, electric motors, and any associated equipment against BIS standards places manufacturers on a good competitive platform while avoiding regulatory setbacks. Understanding the certification procedure, documents required, and benefits will place businesses in good stead to maneuver along the regulatory path and achieve BIS compliance.

As the demand for reliable and energy-efficient motors grows across industries, BIS Certification for Rotary Electrical Machines under Scheme X is becoming not just a regulatory requirement but a competitive advantage.

Whether you’re a manufacturer, importer, or supplier, aligning with BIS standards ensures product quality, legal compliance, and long-term business growth. Don’t let documentation and testing slow you downpartner with Diligence Certification for an expert-guided, efficient approval process.

Contact Diligence Certification for expert guidance on BIS certification for rotary electrical machines—your reliable compliance partner for easy certification services.

Frequently Asked Questions (FAQs)

Is BIS Certification mandatory for all rotary machines?

No, only for models notified under Scheme X. Voluntary certification is also encouraged.

Can imported rotary machines be BIS certified?

Yes. Imports must comply with BIS rules if listed under the mandatory category.

How long does BIS certification take for rotary machines?

On average, 30–60 working days depending on testing timelines and factory audit scheduling.

Is it mandatory to affix the ISI mark on certified machines?

Yes, the ISI mark and license number must appear on product labels and packaging.

Can I apply for multiple models in one application?

Yes, if they are technically similar and covered under the same IS code.

What is the validity of BIS Certification?

Typically 2 years, renewable upon compliance.

Can small manufacturers apply?

Yes, size doesn’t limit BIS eligibility.

Is in-house testing mandatory?

Not mandatory but highly recommended.

What if my product fails BIS tests later?

License may be suspended or canceled.

Can one license cover multiple models?

Yes, if models follow the same IS standard.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

DGCA Certification

DGCA Certification

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration