- BIS Certification for PVC Insulated (Heavy Duty) Electric Cables is mandatory under IS 1554 (Part 1): 1988 for the manufacturing, selling, and supplying of heavy-duty PVC insulated electric cables in the Indian market.

- The BIS Certification ensures that the electric cables are designed as per the standards of resistance to the conductor, insulation thickness, high voltage, and thermal aging.

- The manufacturers are required to perform product testing at BIS-accredited laboratories and a factory inspection to verify the uniformity of quality control practices.

- The BIS license is granted to the manufacturing unit and not to the brand name. This applies to OEMs and private label manufacturers alike.

- The BIS license will enable the use of the ISI mark on the electric cables. This is mandatory for government contracts, PSU purchases, and large-scale infrastructure development projects in India.

Introduction

In the electrical and infrastructure industry in India, instances of compliance failure rarely come to light in the initial stages. Most manufacturers come to know about the issue when their consignment is detained, a tender is cancelled, or a customer asks for documentation related to statutory approval. BIS Certification for PVC Insulated (Heavy Duty) Electric Cables is at the epicentre of this challenge.This certification is a guarantee that the cable has been designed and manufactured in accordance with nationally prescribed standards related to cable design, insulation, conductors, and manufacturing processes. For cable manufacturers, OEM suppliers, and companies interested in government or PSU contracts, this certification has a direct bearing on commercial viability and continuity.

What is IS 1554(Part 1) : 1988 ?

IS 1554 (Part 1): 1988 is an Indian Standard publication by the Bureau of Indian Standards (BIS), which lays down the safety and performance criteria for PVC insulated heavy-duty electric cables with a rated voltage of up to 1100 V. This Indian Standard lays down the norms for the construction of conductors, insulation thickness, electrical resistance, and thermal characteristics of the insulation to provide safe and efficient power distribution. This standard also provides the basis for BIS certification and the use of the ISI mark on heavy-duty PVC insulated electric cables in India.

Key Points

- heavy-duty electric cables made of PVC insulation.

- electric cables that have a maximum working Voltage of 1100 Volts.

- This Standard defines the requirements for Copper and Aluminium Conductors.

- Standard defines requirements of Conductors. These requirements will be the same for both Copper and Aluminium Conductors.

- establishes the Minimum PVC insulation thickness requirements and also establishes the minimum Insulation Standard for PVC insulation.

- specifies the Electrical Tests required for Copper and Aluminium Conductors (i.e. Conductor Resistance Test and High Voltage Test).

- This Standard requires Thermal and Ageing Tests to determine the long-term characteristics of PVC insulation.

- provides requirements for identifying and labelling heavy-duty electric cables.

Why is BIS Certification Mandatory ?

To ensure that electrical cables used in India meet established quality and safety standards, BIS Certification for PVC Insulated (Heavy Duty) Electric Cables are mandatory. According to BIS Act (2016), all products must be certified through BIS based on IS 1554 (Part 1): 1988 specifications. The certification provides safety from potential hazards including, but not limited to,; electrical fires, insulation failure, and short circuit situations.

Key Points

- Legal obligation: Any person selling or manufacturing PVC insulated heavy-duty electric cables without certification from the Bureau of Indian Standards (BIS) will be presumed guilty of an offense and will be punishable by law, which may include fines, confiscation of his goods, or prohibition of his operation.

- Assurance of Safety: Certification will enable you to know what the cable has been tested for, which includes the insulation strength, conductor resistance, and thermal properties; therefore, the inclusion of BSI certification eliminates any risk of fire or electrical shock.

- Assurance of Quality: The BSI certification confirms that a manufacturer follows strict quality assurance systems to maintain consistent product quality over time and not just at the time of product release.

- Understanding Market Access: A valid BIS licence and ISI mark is required to bid on government tenders, for Public Sector Unit (PSU) Procurement or to take part in Large Engineering, Procurement & Construction (EPC) Projects.

- Trusting the Consumer: The ISI mark is the symbol that customers use to determine whether or not a product can provide them with the safety and security they need in a crowded marketplace.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Mandatory legal obligations for the production and distribution of regulated electrical products within the country of India. | Protection against potential penalties, seizure of product, and cancellation of supplier’s license. |

| Verifying compliance with the established product safety and quality criteria. | Minimising risk from electrical incidents, e.g., insulation failure and fire hazards. |

| Verifying that the manufacturing methods used conform to a single standard through auditing and inspection. | Increasing the credibility and stability of the products. |

| A requirement for government procurement via tender and public sector purchases. | Providing access to large scale infrastructure investment projects. |

| Providing the ability to track a product via the marking and documentation process. | Support for conducting audits, inspections, and customer validation. |

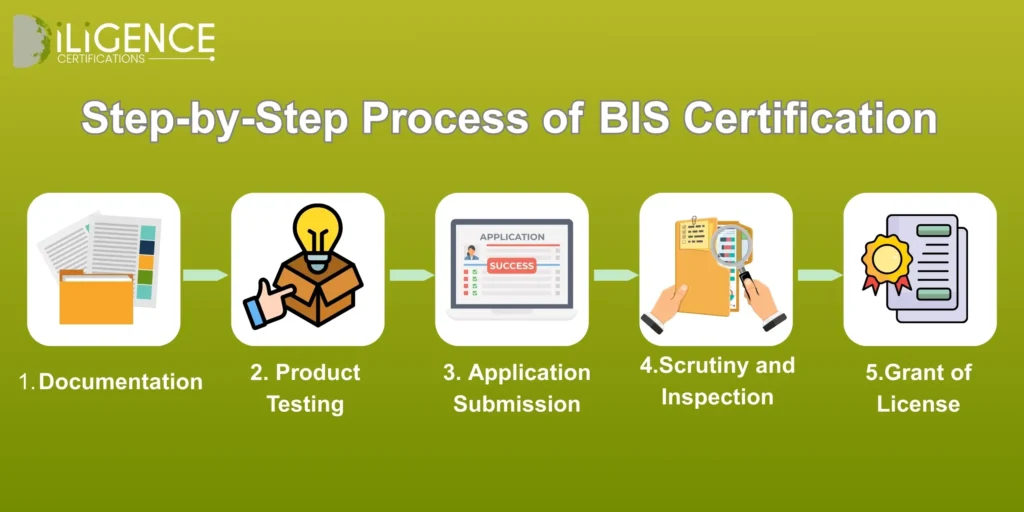

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Company Registration | Certificate of Incorporation / Business Registration proof |

| Manufacturing Unit Details | Factory address proof, layout plan, and list of manufacturing machinery |

| Product Information | Product specification and technical data sheet |

| Quality Control Documents | Quality control manual and in-house testing procedures |

| Test Reports | Product test report from a BIS-recognized laboratory |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- Specialized BIS Expertise: Practical expertise in dealing with BIS Certification for PVC Insulated (Heavy Duty) Electric Cables as per IS 1554 (Part 1): 1988.

- End-to-End Compliance Assistance: From standard mapping and lab coordination to application submission and BIS officer inspection preparation, the entire process is handled in-house.

- Practical, Factory-Level Advice: Support is based on real-world manufacturing issues, not generic checklists—to assist in reducing test failure and inspection disputes.

- Faster, Predictable Timelines: By utilizing pre-audit efforts combined with documented procedures, there is less need for BIS to revisit or change anything with an applicant, which will enhance the speed of the approval process.

- Transparent Communication: There is complete transparency with all costs, timelines and regulatory requirements, with no unexpected surprises or unreasonable expectations.

- Post-Certification Support: Support is provided for marking requirements, surveillance audits, and licence renewals to help maintain compliance with regulatory requirements.

Conclusion

The securement of BIS certification to PVC insulated (heavy duty) electric cables is more than merely complying with regulations and demonstrating that the cables conform to the prescribed safety and performance standards of the country under IS1554 [part1]: 1988. It also provides vendors and manufacturers access to Government Tendering; PSUs purchasing and providing products or services to government bodies and large infrastructure projects. By partnering with an expert organization such as Diligence Certification, you will reduce both the time involved in going through the registration process as well as the risks associated with the registration process. In essence, Diligence Certification provides every aspect of the registration process to the manufacturer and therefore ensures that the manufacturers achieve certification the first time without any gaps and to continuously support a manufacturer in the registration process (including the factory inspections). In addition, partnering with Diligence Certification will provide you with the credibility you need to build trust in your market and ensure that your company can operate with ease when expanding.

Frequently asked questions

Is BIS Certification mandatory for PVC insulated heavy-duty electric cables?

Yes, BIS certification is legally mandatory under IS 1554 (Part 1): 1988 for manufacturing and sale in India.

Which standard applies to heavy-duty PVC insulated cables?

IS 1554 (Part 1): 1988 applies specifically to PVC insulated heavy-duty electric cables.

Who issues BIS Certification in India?

The certification is issued by the Bureau of Indian Standards (BIS).

Is BIS Certification granted to the product or the factory?

The BIS licence is granted to the manufacturing unit, not to the brand name.

When does the BIS Certification expire?

The licence will typically be valid for a period of two years, however, this duration may vary depending on the results of any audit carried out by surveillance authorities.

Will laboratory testing be needed to receive BIS Certification?

Yes, all products being submitted for BIS Certification must be tested in a laboratory that has been approved by the BIS.

Will a BIS Licence cover multiple cable sizes?

Yes, as long as the various sizes have been tested and accounted for in the cross-reference, then one BIS Licence should provide coverage for multiple cable sizes.

Are inspections a requirement for obtaining certification from the BIS?

The BIS will do a factory inspection before giving approval for certification.

Could BIS certification be revoked?

Yes, if the company does not follow the surveillance program or if the ISI Mark is misused.

Does using an ISI mark without getting BIS certified have any consequences?

Yes, using an ISI mark without obtaining BIS certification is against the law and can result in legal punishment.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration