- Crosslinked polyethylene insulated, PVC sheathed cables are utilized widely in both home and business due to their ability to withstand heat, carry heavy weights without damage, and be resistant to water and chemical spills.

- The Bureau of Indian Standards (BIS) ensures that all electrical cables meet the IS 7098 (Part 1): 1988 regulation and these cables are safe, reliable, and manufactured according to Indian law.

- The long-term performance of these cables can be guaranteed only through the appropriate testing of materials used in the production of XLPE PVC cables, including thermal ageing, insulation resistance, and elongation.

- Since there may be a delay in the tender approval process if any part of the electronic documentation submitted for BIS certification is missing or incorrectly prepared, expert guidance is very beneficial for manufacturers.

- BIS certification not only provides manufacturers with the ability to demonstrate adherence to regulations, but also offers manufacturers greater credibility when it comes to participating in government tenders and on a large scale with industrial projects.

Introduction

Crosslinked Insulated PVC Sheathed Cables are a great choice for wiring in factories, businesses, and homes. They really stand out because they can handle heat well, are super strong, and don’t get messed up by water or chemicals.It’s not just about making great cables; they also need to meet the BIS certification requirements under IS 7098 (Part 1): 1988. This is a must if we want to sell them legally in India and be considered for tenders.A lot of manufacturers really struggle with figuring out all the specific testing, paperwork, and factory checks needed to get that BIS approval.Take this cable maker in Gujarat, for example. They had a real headache with incomplete test reports, and it actually slowed down getting those government tender approvals.They got certified, which really boosted their market standing, all because they made sure their processes met BIS standards.These BIS-certified cables, with their special crosslinked insulation and PVC covering, really help to make sure things are safe and dependable. They also meet all the rules, which is great for manufacturers because it helps them stay ahead of the competition.Getting certified isn’t just about staying out of trouble legally; it also really helps open doors for government work and big industrial projects.

What is IS 7098 (Part 1) : 1988 ?

The Standard IS 7098 (Part 1): 1988 specifies the requirements for Crosslinked Polyethylene (XLPE) Insulated, PVC Sheath Cable with a Rated Voltage up to 1100V as per Indian Standards and is also used as the basis of design for these types of cables and manufacturers must meet this standard in order to obtain certification from the Bureau of Indian Standards (BIS) and to comply with Indian Laws.

Key Points

- Voltage Rating: States the maximum voltage rating (up to 1100 V) of cables intended for low voltage applications.

- Insulation & Sheathing: Consists of XLPE insulation and PVC outer sheath providing resistance to temperature and chemicals.

- Testing Requirements: Covers electrical testing (e.g., continuity, earth fault), thermal resistance testing, insulation resistance testing, elongation testing, etc.

- Safety & Performance: The goal of the standard is to make sure that the cables will withstand short circuit situations, mechanical load, and fire.

- Compliance & Certification: A mandatory document to get BIS certification, to submit a bid/offer, and to demonstrate compliance to the market in India.

Why is BIS Certification Mandatory

BIS (Bureau of Indian Standards) certification is an obligatory requirement for a variety of electrical products in India, including Crosslinked Polyethylene Insulated PVC Sheathed Cables. This certification is a guarantee that the cables conform to the IS 7098 (Part 1): 1988 standard. The sale of non-certified cables in India can result in legal prosecution, disqualification in tenders, and even pose a danger to users.

Key Points

- Legal Compliance: Indian regulation requires that IS 7098 (Part 1): 1988 compliant cable is a must for compliance with Indian law.

- Safety Assurance: The cables serve to provide assurance that the cables are compliant with insulation, fire resistance, and electrical performance.

- Tender Eligibility: Compliance with BIS certification is a requirement for participation in Government Tenders & Large Industrial Tenders.

- Market Credibility: BIS Certification provides a means for manufacturers to develop trust with their distributors, engineers, and end users.

- Quality Verification: BIS certification ensures that all materials, design, and manufacturing of the cable have undergone stringent BIS testing.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures compliance with Indian standards (IS 7098 Part 1: 1988) | Legally permits the sale and distribution of XLPE PVC sheathed cables in India |

| Ensures the safety of cables with respect to electrical, thermal, and fire properties | Reduces the chances of accidents, short-circuits, and fire-related hazards |

| Compulsory for government and industrial tender participation | Enhances the selection probability for high-value projects and contracts |

| Certifies the quality of insulation, sheathing, and manufacturing processes | Establishes trust and credibility with customers, distributors, and users |

| Assists in ensuring quality at the industry standard | Improves market competitiveness and brand value |

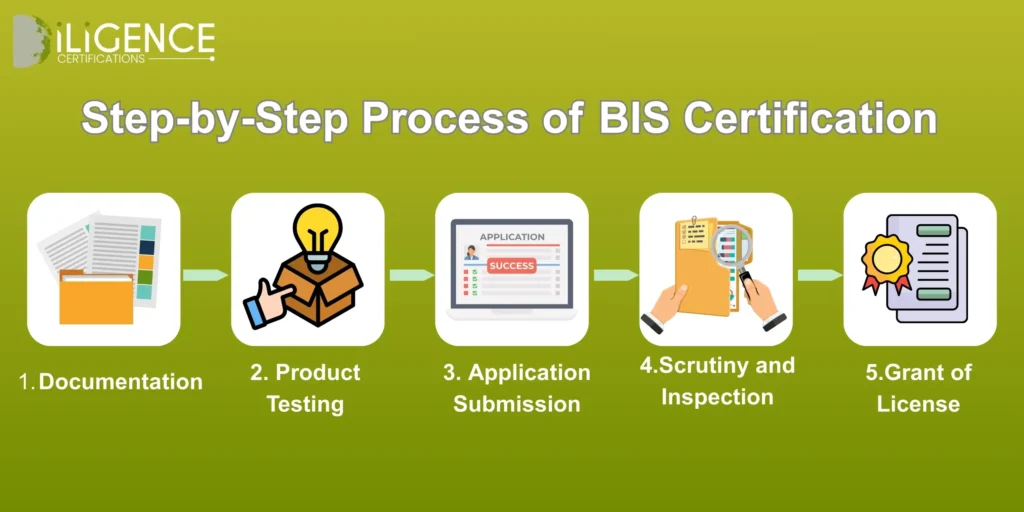

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Company Registration | Certificate of Incorporation / Business Registration proof |

| Manufacturing Unit Details | Factory address proof, layout plan, and list of manufacturing machinery |

| Product Information | Product specification and technical data sheet |

| Quality Control Documents | Quality control manual and in-house testing procedures |

| Test Reports | Product test report from a BIS-recognized laboratory |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- Professional advice on IS 7098 (Part 1): 1988 compliance for XLPE PVC cables.

- Help with preparing proper documentation and sending samples to BIS-approved testing labs.

- Full support for factory audits and inspections to comply with BIS norms.

- Helps obtain BIS certification quickly and easily.

- Helped many industrial and government clients increase chances of tender approval.

- Helps avoid rejection of applications and makes certification easier.

- Helps establish trust and credibility for manufacturers in the electrical and industrial sectors.

Conclusion

BIS Certification for Crosslinked Polyethylene Insulated PVC Sheathed Cables provides the best way for a manufacturer to prove that their Product meets the high safety and reliability standards set forth by the Bureau of Indian Standards. BIS Certification will not only ensure that manufactured cross-linked polyethylene insulated PVC cables meet the technical requirements specified in IS 7098 (Part 1): 1988, but will also enable manufacturers to increase their chances of securing government contracts and attract large industrial orders. The process of achieving BIS Certification can be simplified by working with Diligence Certifications as they will provide you with valuable guidance regarding the documentation, testing and factory audit required to obtain BIS Certification.Their comprehensive assistance ensures that manufacturers obtain certification quickly and gain the confidence of their clients and distributors.BIS-certified manufacturers looking for trusted suppliers of Crosslinked Polyethylene Insulated PVC Sheathed Cables can rely on Diligence Certifications to get their approvals on time and gain a competitive advantage in the market. Get in touch with Diligence Certifications today to make your BIS certification process smoother and kick-start your business with confidence.

Frequently asked questions

What are Crosslinked Polyethylene Insulated PVC Sheathed Cables?

They are electrical cables with XLPE insulation and a PVC sheath, designed for safety, durability, and thermal resistance.

Why is BIS certification required for these cables?

BIS certification ensures compliance with IS 7098 (Part 1): 1988, guaranteeing safety, quality, and legal market eligibility.

What is IS 7098 (Part 1): 1988?

It is the Indian standard specifying requirements, testing, and performance criteria for XLPE PVC sheathed cables up to 1100 V.

Can these cables be sold without BIS certification in India?

No, selling uncertified XLPE PVC cables is illegal and can result in penalties and tender disqualification.

What are the key tests for BIS certification?

Insulation resistance, thermal aging, voltage withstand, elongation, and mechanical strength are primary tests.

How long does BIS certification take?

Typically 6–8 months, depending on testing, documentation, and factory audit readiness.

What documents are needed for BIS approval?

Material specifications, test reports, quality control manuals, and factory process details.

Do manufacturers need factory inspections?

Yes, BIS mandates on-site audits to verify manufacturing processes and quality control systems.

What are the advantages of BIS-certified XLPE PVC cables?

Legal compliance, safety assurance, tender eligibility, and improved market credibility.

How can Diligence Certifications help?

They provide end-to-end support for BIS certification, including documentation, testing guidance, and factory audits.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration