- BIS Scheme X is a voluntary certification for products that are not mandatory for BIS regulations.

- Centrifuges and filtering equipment can be certified for compliance with Indian Standards.

- Applies to industrial, pharmaceutical, chemical, food-grade, and laboratory equipment.

- BIS-certified equipment qualifies for government tenders and export opportunities.

- Valid for 1–2 years, with renewal possible based on compliance.

- Available for both Indian and foreign manufacturers under respective schemes.

Introduction

About the idea, these modern industrial establishments exercise quality control in their products and operational efficiency of centrifuges and filtering-and-purifying apparatuses for fluids and gases. Such machines find application in the pharmaceutical, food and beverage, environment services, and chemical processing. The Bureau of Indian Standards plays a vital role in BIS Scheme X Certification for centrifuges to maintain safety, performance, and compliance at the highest levels. It is essential to understand the BIS Scheme X for centrifuges and filtration equipment to ensure legitimate access to the market and create customer confidence. This certification is specifically for centrifuges and machines for filtering and purifying.

BIS scheme X certification is not only a regulatory formality for manufacturers who wish to set up their business in India, but it is also a guarantee of quality for them. This detailed guide thoroughly covers the different types of centrifuges, filtering, and purifying machinery, their sub-assemblies and components, along with how BIS Scheme X Certification is a significant contributor toward ensuring safety and compliance.

What is the BIS Scheme X Certification?

In India, the Bureau of Indian Standards (BIS) is known to be the national standards body responsible for the formulation and enactment of standards for different products, services, and systems. BIS Scheme X certification is one of the product certification schemes that is applicable to various types of machinery, including centrifuge filtration systems and associated components thereof.

BIS product certification makes it assure that their product, such as centrifuges and filtering equipment, has met these standards, which are different from various industries from manufacturer and importers.

BIS certification is not only a compliance mark but also a trust and assurance of quality to the customer-supplier-regulatory body. Endorsed safety laws for quality and performance requirements are catered for in the assured marketing of BIS-certified machinery by the manufacturer in his geographical area, in which is India.

Types of Centrifuges

Centrifuge, the specialized apparatuses, separate different particles from liquids or gases. There are different types of centrifuges for different applications and industries. Below are the most common types:

1. Decanter Centrifuge

- Decanter Centrifuge finds the greatest application in the continuous separation of liquids-suspended solids or liquid-liquid phase separations. In petroleum and natural gas, food processing, and wastewater treatment, decanter centrifuges are very popular. These decanters are effective for production operations that require a continuous, high-performance separation.

- Applications include: Separating oil and water, clarifying liquids, or dewatering sludge.

- BIS Certification: As per BIS Scheme X, decanter centrifuges have specific performance and safety standards, including materials of construction, rotor speed, and durability of components against failures.

2. Disc stack centrifuge

- A disc stack centrifuge is utilized to separate minor particles from the liquid phase, generally where high separation efficiencies are required. Typical applications for this type of centrifuge would include the dairy, pharmaceutical, and chemical manufacturing industries.

- Applications: For clarification of liquids, separation of fine particles, and purification of fluids.

- The disc stack centrifuge must withstand high speeds and operate under pressure without failure. The BIS standards ensure the machine’s safety, efficiency, and performance.

3. Basket Centrifuge

- Basket centrifuges work under batch mode, and these are used in industries where periodic separation is required, for instance, pharmaceuticals, food processing, and mining. Basket centrifuges are particularly effective for solid-liquid separation industrially.

- Applications: Basket centrifuges are used for batch-wise filtration and separation, especially in large-scale solid-liquid separation.

- BIS Certification: These basket centrifuges are tested on structural integrity, cleanliness, and reliability after multiple cycles for the BIS certification.

4. Laboratory Centrifuge

- Laboratory centrifuges are employed in small-scale activities and research. Laboratory centrifuges are appropriate for separating blood and urine and other biological fluids from medical laboratories and research in biochemistry and molecular biology.

- Applications: Commonly applied in research laboratories, hospitals, and diagnostic laboratories.

- BIS Certification: The laboratory centrifuge has BIS certification for precise calibration, accuracy, and safety standards, particularly in connection with biological sample applications.

5. Continuous Flow Centrifuge

- Continuous flow centrifuges are meant to withstand high-throughput flow processes in which large quantities of liquids must be processed continuously. Generally, applications are in the chemical, pharmaceutical, and food processing industries.

- Applications: Continuous separation of liquid/solids in production plants of high volumes.

- BIS Certification: Continuous flow centrifuges must comply with very stringent standards of high operational efficiency, performance, and reliability requirements-since these are a requirement of large-scale industries.

Filtering and Purifying Machinery for Liquids and Gases

Machine filtration and purification are the terms that describe removing contaminants from liquids and gases, which are important in many industrial processes. It plays a vital role in assuring that the final product is according to established standards and safe and environment healthy. The following sets of some commonly used types of filtering and purifying machinery:

1. Liquid Filtration Systems

- These systems are designed to eliminate all suspended solids, contaminants, and microorganisms from a liquid. They range from those used for purification to pharmaceuticals to food processing.

- Application: Water purification, filtration of food and beverage products, and pharmaceutical manufacturing.

- BIS Certification: BIS certifications for liquid filtration systems include parameters such as construction materials, filtration efficiency, and safety features.

2. Gas Purification Systems

- These purification systems are employed in the removal of impurities from gaseous streams, such as almost entirely water vapor, particulates, and beyond, the good old, harmful contaminants. All this has found an important role in a number of industries like oil and gas, chemical ventures, and even hospital settings holding pharmaceuticals.

- Applications: Removal of impurities from gaseous industrial, medical, and environmental gases.

- According to the BIS Scheme-X, gas purification systems would have to adhere to stringent standards on gas quality, filtration capacity, and system reliability.

3. Air Filtration Units

- An air filtration device serves to purify air when used in an industrial, commercial, or domestic environment. The systems are designed to remove dust and other particles harmful to human beings from the air along with other matter, such as allergens. The air filtration systems are excellent in maintaining cleanliness and safety in industries like electronics, pharmaceuticals, and automobile manufacturing.

- Application: Cleanrooms, air conditioning systems, and environmental air quality control.

- BIS Certification: Air filtration units are expected to fulfill the standards for the removal of particles, operational lifespan, and integration of systems.

4. Membrane Filtration and Reverse Osmosis Systems

- Membrane filter systems, especially reverse osmosis, are among the most common forms of purification for liquids and the removal of dissolved salts, organics, and particles. Such systems are, therefore, very critical in industries requiring pure water or chemical processing.

- Application: Desalination, water purification, and wastewater treatment.

- BIS Certification: These systems must comply with BIS standards for membrane life, filtration efficiency, and energy use.

Assemblies/Sub-assemblies and Components

Centrifuges and filtration systems, as noted above, are composed of many types of assemblies and components. The components must also meet acceptable standards for safety, efficiency, and performance. Some of the major assemblies and components are:

1. Centrifuge Rotors

The rotor is a key component inside the centrifuge, supporting samples and spinning them at very high speeds. It is under the regulations of the Bureau of Indian Standards such that it has the integrity to witness mechanical stresses in operation, thus ensuring performance and safety.

2. Filter Cartridges and Membranes

These parts are important components of the filtration system, which filter contaminants and purify liquids or gases. The Bureau of Indian Standards certifies that filter cartridges and membranes are made of durable materials, capable of effectively filtering specific contaminants.

3. Gas Separation Units

Gas separation units are designed for the gas purification systems to separate the different components of gases. These units must conform to high standards of quality to ensure that their separation and purification process is free from any leakage and/or contamination.

4. Pump Assemblies

All pumps are used for the transfer of liquids through centrifuges and filtration systems. The Bureau of Indian Standards certifies pumps designed for efficient transfer of fluids and basically on durability and reliability.

5. Control Systems

Modern centrifuges and filtration systems are archived with an advanced level of control and monitoring systems for regulation of their operation. These systems need to conform to the Bureau of Indian Standards in terms of accuracy, reliability, and intelligibility.

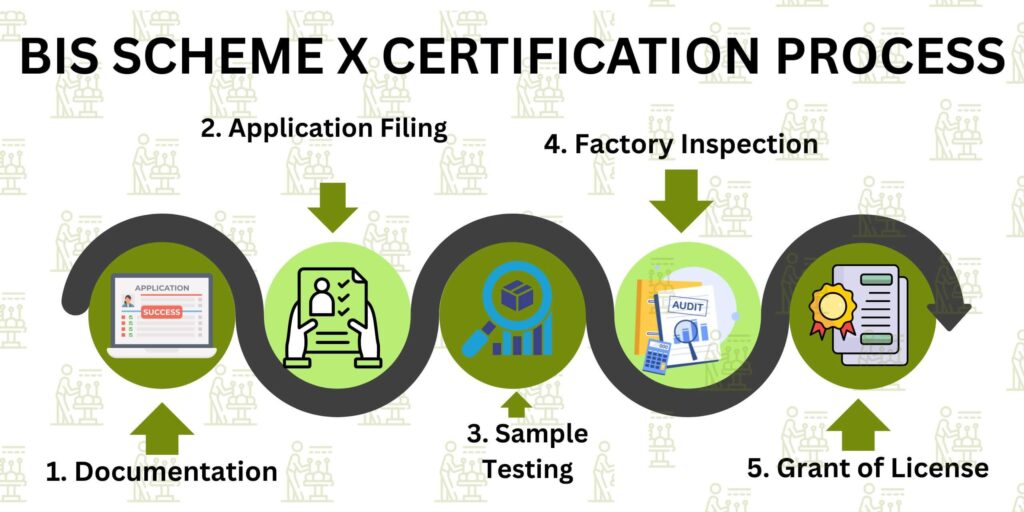

BIS Scheme X for centrifuges Process

BIS scheme X certification involves several steps that validate that machines and machine components conform to certain standards. The procedure usually consists of:

Step 1: Application for BIS X Scheme

The first stage is application for BIS X Scheme certification. In applying for BIS X Scheme certification for the centrifuge, the producer shall supply detailed information on the product, such as:

Product Specifications: Fully describes the design, function, and features.

Company Details: Description of the manufacturer, production plant, and quality control.

Compliance with Indian Standards: Indications regarding the conformity of the product within the ambit of the relevant BIS standards.

Documentation Required: Drawings, catalogues, test reports, and material certifications.

Step 2: Product Testing

After the application has been received, product testing will be conducted next. The product will be tested in an accredited laboratory for compliance with BIS standards. The testing relates to:

Performance: The machine should work in a satisfactory manner under various conditions.

Safety: There are tests to ensure the product has no electrical hazards.

Durability and Reliability: Evaluation of machine performance over long periods and under changing conditions.

A successful test report is necessary for further action.

Step 3: Factory Inspection

Post-product test passing, the factory inspection will be carried out by BIS. During this inspection, the production system will be assessed to ensure having adequate setup, quality control, and procedures for consistently producing compliant goods. The inspection will focus on:

Manufacturing Process: Imparting application of production processes as per BIS standards.

Quality Control: Application of quality checks throughout production.

Working Condition: The entire factory environment is checked against the regulations.

Step 4: Issuance of BIS License

Upon successful testing and inspection, BIS issues the certificate that consists of a BIS license number certified, which is to be affixed to the product or its packaging. Certification indicates that the products comply with all pertinent standards. The certification encompasses:

Period of Validity: BIS certification normally remains valid for 1-3 years after which it must be renewed.

License Number: A unique identification number is given to the product.

Step 5: Surveillance and Renewal

Once certified, the product remains under surveillance to check continued compliance with BIS standards. Period audits and checks of the products are carried out by BIS while the manufacturer shall ensure maintain production quality for the certification to be awarded. Also, manufacturers must apply for renewal of certification at specified intervals, which may involve retesting and factory audit.

How Diligence Certification Can Help You Achieve BIS Scheme X Certification

Fulfilling BIS Scheme X certification for centrifuges, filtration, and purifying machinery is quite a long process, and requires careful planning, proper execution, and compliance with the standards. Diligence Certification is taking this process entirely to you, so your manufactured product is ready for the market of India.

Here is how we will support you:

- Initial Assessment: we start with your machinery along with understanding the value with specific standards for these products based on BIS Scheme X.

- Compliance Guidance: We provide you straightforward guidance on how to get started with the BIS specifications, covering technical specification, materials, and performance metrics.

- Streamlined Application Process: We help in completing and forwarding the BIS application, making sure that all of the required documents are in place while deadlines are met.

- Testing Coordination: We assist you in coordinating accredited laboratories in testing and inspection of your products.

- Factory Inspection Preparation: We make sure that your site is ready for, and meet the standard instituted by BIS for manufacturing processes, in these factory inspections.

- Ongoing Monitoring: We continually monitor and support your product with BIS compliance and renewals whenever required.

Conclusion

With BIS Scheme X certification solicited by manufacturers and importers of centrifuges and machinery for filtering and purification, compliance with Indian standards becomes mandatory. Whether it is a decanter centrifuge or gas purification system or filtering unit, BIS certification is for products to ensure defined performance, safety, and quality.

Diligence Certification offers expert consulting services that will guide you through the process of getting BIS certification for your products to be ready for the market in India. Regardless of the scale of your manufacturing, whether small or large, you can partner with us and learn the easy way to get through the unwieldy process.

For information about our assistance in achieving BIS Scheme X certification for your products, please contact us.

Frequently Asked Questions

What is BIS Scheme X?

A voluntary certification scheme for voluntary products from the Bureau of Indian Standards.

Is BIS certification mandatory for centrifuges or filtration equipment?

No, it’s voluntary under Scheme X

Why should I get BIS Scheme X for my equipment?

To prove quality, gain trust, and access larger markets and government contracts.

Who can apply for this certification?

Indian manufacturers and foreign manufacturers through the FMCS route.

What types of equipment are eligible?

Industrial centrifuges, lab centrifuges, membrane filters, cartridge filters, vacuum filters, etc.

What’s the certification process?

Online application → document submission → product testing → factory audit → BIS license grant.

How long does certification take?

Typically 4 to 8 weeks depending on testing and audit readiness.

Can I use the ISI mark after certification?

Yes, certified products can bear the ISI mark under BIS Scheme X.

What is the validity of the license?

The license is valid for 1–2 years and is renewable.

Does BIS certification help with exports?

Yes, it enhances product acceptability in both domestic and international markets.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration