- Obligatory quality compliance for artificial transmission chains in India

- Covers comber chains, backcountry chains, attachments, and associated sprockets

- Ensures strength, dimensional delicacy, and interchangeability

- needed for manufacturers and importers before request trade

- BIS mark builds buyer trust and reduces specialized controversies

Introduction

Precision Roller And Bush Chains perfection comber and backcountry chains are small factors with an outsized part. They still transfer power across machines in manufactories, shops, conveyors, agrarian outfit, and innumerous mechanical systems. When these chains fail, the impact is immediate — time-out, safety pitfalls, and expensive repairs. That’s exactly why BIS Bureau of Indian Standards. under IS 24032014 exists. This Indian Standard was introduced to bring thickness to chain design, material quality, confines, and performance. It aligns Indian manufacturing with global mechanical transmission prospects while addressing original operating conditions like dust, cargo variation, and long operating hours.

What Is BIS Certification for IS 2403:2014?

BIS instrument under IS 24032014 is a conformity assessment that verifies whether short- pitch transmission perfection comber chains, backcountry chains, their attachments, and chain sprockets meet the conditions set by the Bureau of Indian norms.

The standard specifies

- Dimensional forbearance

- Material grades

- Mechanical parcels

- Test styles for strength and continuity

- Marking and traceability conditions

Once certified, the manufacturer is fairly allowed to apply the ISI Mark, indicating compliance with Indian quality morals.

Key Features of IS 2403:2014

- Covers both comber and backcountry chain constructions

- Applies to transmission chains used for power transmission, not lifting

- Specifies pitch, comber periphery, plate consistence, and range

- Defines minimal tensile strength and breaking cargo

- Includes associated sprockets to insure comity

This focus on interchangeability is critical. Chains and sprockets from different batches or indeed different manufacturers — must work together without inordinate wear and tear or misalignment.

Why BIS Certification Is Required – Key Reasons

- functional Safety – Chain failure can beget machine damage or worker injury.

- Standardization – Livery confines help mismatched sprockets and chains.

- request Regulation – Prevents unacceptable significances and low- quality original products.

- Artificial trustability – Ensures predictable performance in nonstop operations.

- Legal Compliance – Dealing uncertified products can attract penalties and seizure.

- In numerous artificial tenders, BIS instrument is n’t voluntary. It’s a birth demand.

Importance and Benefits – Side-by-Side Comparison

| Importance | Benefits |

| Ensures minimal quality marks | Reduced breakdowns and conservation |

| Regulates material composition | Longer chain life under cargo |

| Confirms dimensional delicacy | Smooth power transmission |

| Validates mechanical strength | Advanced functional safety |

| Enforces traceability | More client confidence and brand value |

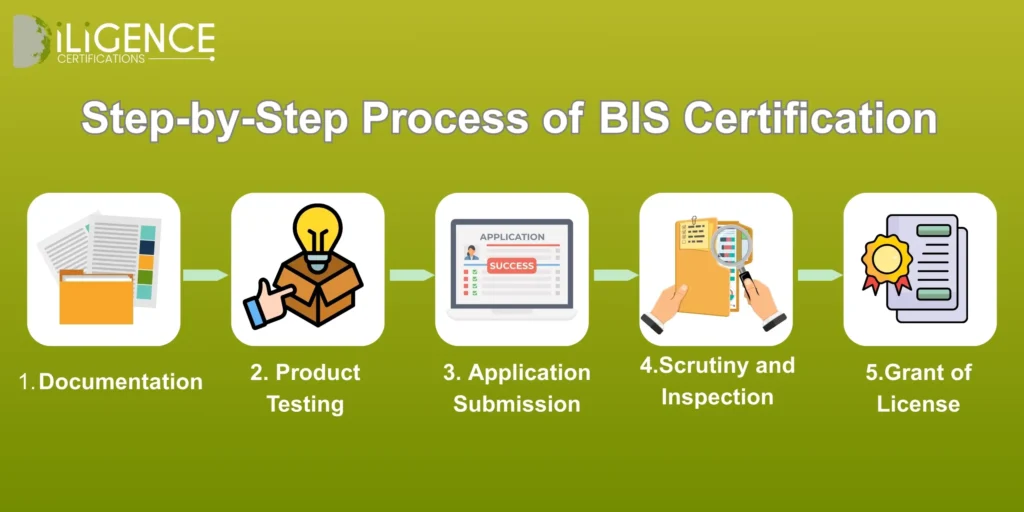

The BIS Certification Process (Raw, Practical View)

While the sanctioned way look straightforward on paper, the prosecution frequently is n’t. The process generally involves

- operation form with product details

- plant examination by BIS officers

- Sample selection and testing at BIS- honored labs

- Review of test results and manufacturing controls

- entitlement of license and authorization to use ISI mark

Each stage has attestation, timelines, and specialized scrutiny that can delay blessing if not handled precisely.

Challenges When Applying Without a Consultant

numerous manufacturers try to manage BIS instrument on their own and face recreating roadblocks

- Incorrect product bracket leading to rejection

- Deficient test samples that fail lab conditions

- misapprehension of IS 2403 clauses

- Detainments in examination scheduling

- Non-conformity in plant quality control records

The most common issue is n’t product quality — it’s procedural crimes. BIS processes are detail- driven, and indeed minor attestation gaps can stall blessing for weeks or months.

Why Choose Diligence Certificate Consultancy

Diligence Certificate Consultancy works at the crossroad of regulation and real manufacturing conditions. rather of treating BIS instrument as a roster, the approach is practical and preventative.

- Then’s what sets it piecemeal

- Clear evaluation of product compass under IS 24032014

- Pre-testing guidance to avoid lab failures

- End- to- end collaboration with BIS authorities

- Support during plant examination medication

- Faster resolution of specialized queries and expostulations

For manufacturers, this means lower dislocation to product and faster request entry. .

Long-Term Business Impact of BIS Certification

Once certified, the advantages go beyond compliance. BIS- marked chains are easier to vend to OEMs, EPC contractors, and government buyers. Export credibility also improves, as numerous overseas buyers see BIS as a strong public quality standard.

Over time, instrument helps manufacturers regularize internal processes, reduce rework, and align with transnational norms like ISO and DIN coequals.

Conclusion

BIS instrument for Short- Pitch Transmission Precision Roller and Bush Chains under IS 24032014 is n’t just about meeting a legal demand. It’s about proving that a critical mechanical element can perform reliably under pressure. In diligence where time-out is precious and safety isnon-negotiable, certified chains offer consolation.

Manufacturers who approach this instrument strategically — especially with educated consultancy support — do n’t just get approved briskly. They make a stronger, more trusted product line that stands up in competitive requests.

Frequently Asked Questions (FAQs)

Is BIS instrument obligatory for comber chains under IS 24032014?

Yes, for regulated products intended for trade in India, instrument is obligatory.

Does the standard cover sprockets as well?

Yes, associated chain sprockets are included to insure comity.

How long does BIS instrument take?

generally 6 – 12 weeks, depending on attestation and test results.

Are significances also needed to misbehave?

Yes, importers must gain BIS instrument before dealing in India.

What happens if uncertified chains are vended?

Authorities may put penalties, seize goods, or ban deals.

Is product testing mandatory?

Yes, samples must be tested at BIS- honored laboratories.

Can one certify cover multiple chain sizes?

Only if they fall within the approved compass and specifications.

How long is the BIS license valid?

generally one time originally, with renewal options.

Does BIS instrument guarantee zero failure?

No, but it ensures compliance with defined safety and quality limits.

Why use a BIS adviser rather of applying directly?

10. Why use a BIS adviser rather of applying directly?

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration