- BIS Certification for Crosslinked Polyethylene Insulated PVC Sheathed Cables Under IS 7098 (Part 3) : 1993 faced lines meet Indian safety, quality, and performance norms, reducing pitfalls of fire, electrical faults, and sequestration failure.

- Crosslinked polyethylene sequestration offers high thermal stability, chemical resistance, and mechanical continuity, making it ideal for artificial, marketable, and domestic operations.

- IS 7098( Part 3) 1993 specifies specialized conditions similar as captain size, sequestration consistency, voltage standing, and jacket quality for PVC- faced lines.

- Manufacturers must undergo rigorous testing and attestation — including type tests, routine tests, and plant checkups — to gain BIS instruments and fairly sell their lines in India.

- BIS instrument not only ensures compliance with Indian law but also enhances brand trust, facilitates design blessings, and supports import eventuality for XLPE isolated lines.

Introduction

In 2023, a leading electrical contractor in Pune faced repeated design detainments because the XLPE isolated PVC faced lines they sourced were n’t BIS- certified. Despite meeting transnational norms, the absence of BIS instruments created roadblocks during examinations and blessings for a high- rise marketable design. This script is far from uncommon in India, where compliance with Crosslinked Polyethylene Insulated PVC Sheathed Cables IS 7098( Part 3) 1993 is obligatory for crosslinked polyethylene( XLPE) isolated lines with .BIS instrument serves as a hallmark of safety, quality, and trustability, icing that lines repel thermal, mechanical, and chemical stresses without compromising performance. For manufacturers, securing this instrument is n’t just a nonsupervisory formality, it’s a strategic advantage that builds trust with contractors, design directors, and end- druggies. In this companion, we explore the nuances of the BIS instrument for XLPE PVC faced lines, breaking down the norms, testing procedures, and practical way that businesses in India need to follow.

What is IS 7098 (Part 3) : 1993 ?

BIS Certification for Crosslinked Polyethylene Insulated PVC Sheathed Cables IS 7098( Part 3) 1993 is the Indian Standard specification for Crosslinked Polyethylene( XLPE) isolated PVC faced lines for rated voltages up to and including 1100 V. It defines the specialized conditions, testing procedures, and safety morals that manufacturers must follow to insure trustability, continuity, and safety of lines used in domestic, marketable, and artificial installations. This part of the standard specifically covers XLPE sequestration with PVC external sheathing, combining thermal and mechanical robustness with honey- retardant parcels suitable for Indian conditions.

Key Points

- Covers XLPE isolated PVC faced lines rated up to 1100 V.

- Specifies captain size, sequestration consistency, and current capacity.

- Ensures thermal stability, chemical resistance, and mechanical strength.

- authorizations type and routine testing for safety and quality.

- Guarantees trustability, fire safety, and long- term performance.

Why is BIS Certification Mandatory

BIS( Bureau of Indian Standards) instrument is obligatory in India for XLPE isolated PVC faced lines because it ensures compliance with safety, quality, and performance norms BIS Certification for Crosslinked Polyethylene Insulated PVC Sheathed Cables under IS 7098( Part 3) 1993. Without this instrument, manufacturers can not fairly request lines in India, and contractors threaten detainments, safety hazards, and nonsupervisory penalties. Basically, the BIS instrument acts as a guarantee of trustability, safety, and adherence to Indian electrical morals.

Key Points

- Ensures legal compliance for marketing and operation of lines in India.

- Guarantees stoner safety by minimizing fire, short- circuits, and sequestration failures.

- Confirms harmonious quality through rigorous testing and checkups.

- Builds request credibility and trust among contractors and guests.

- Facilitates design blessings and supports import readiness.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Legal requirement for manufacturing and selling cables in India | Ensures cables are legally approved for sale and use |

| Confirms compliance with IS 7098 (Part 3) : 1993 standards | Guarantees high-quality, reliable performance |

| Minimizes safety risks like fire and electrical hazards | Provides enhanced user safety and reduces installation risks |

| Builds industry credibility for manufacturers | Increases customer trust and market reputation |

| Required for government and large-scale projects | Facilitates project approvals and export opportunities |

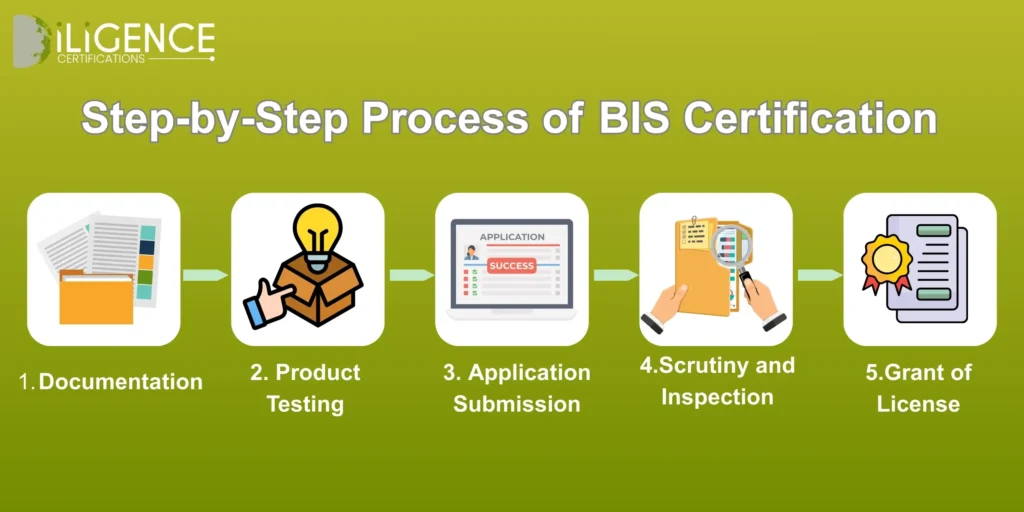

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Company Registration | Certificate of Incorporation / Business Registration proof |

| Manufacturing Unit Details | Factory address proof, layout plan, and list of manufacturing machinery |

| Product Information | Product specification and technical data sheet |

| Quality Control Documents | Quality control manual and in-house testing procedures |

| Test Reports | Product test report from a BIS-recognized laboratory |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- moxie in BIS Certification Times of experience guiding manufacturers through IS 7098( Part 3) 1993 compliance and blessings.

- End- to- End Support From attestation, testing, to submission, we manage the complete instrument process efficiently.

- Trusted by Assiduity Leaders Worked with top string manufacturers and electrical contractors across India.

- Faster blessings Streamlined procedures and pre-audit checks reduce detainments in instrument timelines.

- tailored results acclimatized consulting for small, medium, and large- scale manufacturers, addressing specific compliance challenges.

- Regulatory Updates Keep guests informed about rearmost BIS guidelines, emendations, and testing morals.

- Quality & Safety Focus ensure your products meet safety, trustability, and performance norms, boosting customer trust.

Conclusion

Securing a BIS instrument for XLPE isolated PVC faced lines under IS 7098( Part 3) 1993 is further than a nonsupervisory demand; it’s a commitment to quality, safety, and trustability. From icing compliance with Indian norms to enhancing brand credibility and easing design blessings, BIS instrument is an essential corner for manufacturers and contractors alike. Diligence Certifications At industriousness instruments, we guide businesses through every step of the instrument process, offering expert advice, end- to- end support, and timely blessings. Partnering with us ensures your lines meet safety norms, repel rigorous testing, and gain request trust, making your products ready for both domestic systems and import openings.

Take the coming step toward nonsupervisory compliance and assiduity recognition with industriousness instruments. Your commitment to quality starts then.

Frequently asked questions

What's the BIS instrument for XLPE PVC faced lines?

BIS instrument ensures the lines meet IS 7098( Part 3) 1993 norms for quality and safety.

Is BIS instrument obligatory in India?

Yes, the BIS instrument is fairly needed for manufacturing and dealing low- voltage XLPE PVC faced lines.

What does IS 7098( Part 3) 1993 cover?

It specifies captain size, sequestration, voltage standing, and PVC jacket conditions for XLPE lines up to 1100 V.

Why is the BIS instrument important?

It ensures safety, performance, trustability, and nonsupervisory compliance for lines.

How long does the BIS instrument process take?

generally, the process takes 4 – 8 weeks, depending on attestation and testing completion.

What tests are needed for a BIS instrument?

Type tests and routine tests, including voltage repel, sequestration resistance, and honey retardancy.

Can Cannon-BIS pukka lines be sold in India?

No, dealing non-BIS pukka lines can affect legal penalties and design rejection.

Who can apply for the BIS instrument?

Manufacturers or importers of XLPE isolated PVC faced lines in India.

Does BIS instrument ameliorate request credibility?

Yes, it builds trust with contractors, masterminds, and guests and is frequently obligatory for large systems.

Can BIS- certified lines be exported?

Yes, the instrument helps meet domestic and transnational compliance, supporting import readiness.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration