- Test of Wheels or Rims for Trucks and Buses help to guarantee safety by complying with strength and continuity conditions, therefore greatly minimizing the threat of accidents due to wheel failure.

- IS 9438 Standard Establishes conditions for the material, dimension, mechanical parcels, and cargo, bearing characteristics of bus skirtings for heavy vehicles.

- In addition to visual examinations and chemical analyses, the tests also comprise tensile and hardness tests, as well as static and dynamic cargo impact tests, that are designed to mimic operation in nature.

- Constant Surveillance The Bureau of Indian norms( BIS) carries out regular examinations to check if the IS 9438 standard is being complied with continuously. In this way, it ensures responsibility and public safety.

- Instrument Process Involves product testing in BIS- approved labs, plant checkups, and allocation of the ISI mark to biddable manufacturers.

- Ongoing Surveillance BIS conducts periodic checks to maintain nonstop compliance with IS 9438, icing trustability and public safety.

Introduction

BIS (Bureau of Indian Standards) is a public norms body which oversees and maintains the quality, safety, and trustability of products and services in India. It sets norms for different diligence and awards instruments to those manufacturers whose products conform to the standards.BIS instrument of Test of Wheels or skirtings for exchanges and motorcars shows that heavy vehicle bus and skirtings meet the safety, strength, and continuity conditions as per IS 9438. As bus and skirtings are the corridors that bear heavy loads and dynamic stresses, this instrument is veritably crucial.Apart from icing the quality of the product, by means of its instrument, BIS also enhances the safety as well as the credibility of exchanges and motorcars operating in India.

What is IS: 9438?

IS 9438 is an Indian Standard that specifies the requirements and testing methods for Wheels or Rims for Trucks and Buses. It is a kind of assurance that the wheels of such heavy vehicles will be strong, safe, and durable not just under the normal operating conditions but also when subjected to extreme ones. The standard incorporates provisions relating to the material, design, size, mechanical properties, and loading capacity.

Key Points:

- Scope: Visual defects, cracks, and uniformity inspection along with testing for the strength of a compacted rim are required.

- Material Requirements: Specifies the quality of the steel/alloy, chemical composition, and mechanical properties like tensile strength and hardness.

- Dimensional Standards: The wheel/rim dimensions, tolerances, and design criteria for ensuring the proper fitment are defined.

- Load & Fatigue Testing: This standard defines the maximum weight a wheel can support by static load tests, it also simulates repeated stress through dynamic/fatigue tests.

- Impact and Safety Tests: They ensure wheels can withstand shocks and impacts without failure.

- Quality Control: Visual defects, cracks, and uniformity inspection along with testing for the strength of a compacted rim are required.

- Compliance for Certification: Passing the IS 9438 tests is necessary to get the BIS certification and ISI marking for commercial use.

Why is BIS Certification Mandatory

BIS Certification (Bureau of Indian Standards) is compulsory for certain items such as wheels and rims on trucks and buses. This is to ensure that they are safe, of good quality, and reliable. Wheels are very important because they support a heavy load and get quite a rough treatment on the road. If they are defective or non compliant with the regulations, it could result in accidents, vehicle breakdowns and even injuries.

Key Points:

- Quality Control – Checks every batch of steel or aluminium, each rim’s width, offset and bolt pattern plus every heat treatment or welding pass, against the limits written in IS 9438.

- Legal Requirements – Indian law bars sale of any truck or bus wheel or rim without proof it meets IS 9438 – trucks found with uncertified rims are taken off the road and the supplier pays fines.

- Consumer Protection – A rim that has passed the BIS tests will not crack when it hits a pothole at full load – drivers are less likely to face sudden wheel failure.

- Market Credibility – Once the Bureau of Indian Standards issues the licence, the maker stamps the ISI logo on the rim – fleet buyers recognise the mark but also place larger orders, while drivers trust the wheel will hold air and load.

Importance and Benefits of BIS Certification

| Importance | Benefits of BIS Certification |

| guarantees adherence to heavy vehicle wheel safety regulations. | ensures that customers will receive dependable and high-quality items. |

| Verifies that wheels and rims satisfy IS 9438’s material, design, and strength standards. | grants authorization to sell in the Indian market. |

| prevents wheel failures and collisions, protecting both the general public and drivers. | uses the ISI mark to increase consumer trust and brand credibility. |

| unifies the industry’s manufacturing procedures. | increases certified firms’ ability to compete in the market. |

| assists regulatory bodies in keeping an eye on and enforcing safety and quality regulations. | lowers manufacturer liability and recall risks. |

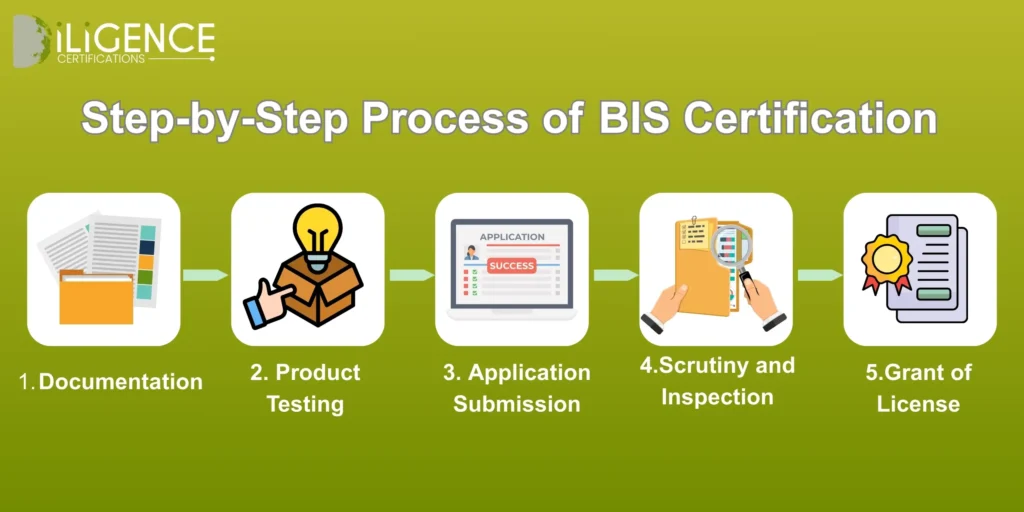

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Company Registration | Certificate of Incorporation / Business Registration proof |

| Manufacturing Unit Details | Factory address proof, layout plan, and list of manufacturing machinery |

| Product Information | Product specification and technical data sheet |

| Quality Control Documents | Quality control manual and in-house testing procedures |

| Test Reports | Product test report from a BIS-recognized laboratory |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

- We really know our stuff when it comes to BIS Certification.

- We’re especially good at helping you with the wheels/rims BIS certification process, providing expert guidance every step of the way.

- You save time because it keeps things moving smoothly.

- There are no holdups with applying, testing, or writing things down.

- We make sure testing is on time and correct by working with labs that BIS has approved.

- This makes sure that manufacturers and their products follow BIS rules, which is crucial for safety and standards.

- We handle the whole thing, from when you apply right through to when your license is issued.

Conclusion

Diligence Certifications is a partner manufacturers can really count on when they need BIS Certification for Wheels or Rims for Trucks and Buses, specifically for IS 9438.We guide you every step of the way, making sure all your papers are just right. We even link you up with BIS-approved labs and help you from start to finish, from applying to getting your license, so certification goes smoothly.Getting BIS certification with Diligence Certifications means your wheels and rims hit the top marks for safety, how long they last, and overall quality. This really keeps everyone safer, both the people driving and those around them.Having the ISI mark really helps a product look more trustworthy in the market, makes people feel good about buying it, and keeps manufacturers out of legal trouble.

Frequently asked questions

What's BIS Certification?

BIS instrument ensures products meet Indian safety, quality, and performance norms.

Why is BIS Certification demanded for bus skirtings?

To guarantee safety, continuity, and compliance with IS 9438 norms for exchanges and motorcars.

What does IS 9438 cover?

IS 9438 specifies material, design, mechanical parcels, cargo, and impact testing for heavy vehicle buses.

Which bus needs a BIS Certification?

All sword or amalgamation bus skirtings for exchanges and motorcars vended in India bear BIS Certification.

What tests are conducted under IS 9438?

Tests include dimensional examination, material analysis, static/ dynamic cargo tests, and impact tests.

Who issues BIS Certification?

The Bureau of Indian norms( BIS) subventions instruments after testing and plant inspection.

Can a company sell buses without BIS Certification?

No, dealing non-certified bus skirtings for exchanges and motorcars is illegal in India.

How long does BIS Certification take?

generally, 2 – 6 months depending on testing, attestation, and plant inspection completion.

What's the role of industriousness instruments?

They give expert guidance, testing collaboration, and end- to- end support for BIS instruments.

What are the benefits of BIS Certification?

Ensures safety, legal compliance, quality assurance, request credibility, and consumer trust.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration