- Mandatory electrical separating mats meet Indian safety and quality conditions.

- IS 15652:2006 Insulating Mats for Electrical specifies material, consistency, and construction norms for separating mats.

- Mats are tested for dielectric strength, electrical resistance, and leakage current.

- Ensures protection of the labor force against electric shock in high- voltage surroundings.

- BIS mark assures continuity, safety, and dependable performance in electrical workplaces.

Introduction

BIS Certification for Insulating Mats for Electrical under IS 15652:2006 is an obligatory quality demand in India to ensure electrical safety at workplaces. These mats are used in front of electrical panels and switchgear to cover labor force from electric shock. The standard defines essential safety, performance, and testing conditions, and the BIS mark confirms that the separating mats misbehave with prescribed electrical and continuity morals.

What is IS 15652:2006?

IS 15652:2006 Insulating Mats for Electrical is an Indian Standard issued by the Bureau of Indian standards( BIS) that specifies the conditions for electrical separating mats used to give protection against electric shock. The standard defines criteria for material quality, consistency, electrical resistance, and dielectric strength. It also prescribes obligatory tests to ensure the mats are safe, durable, and suitable for use in electrical installations similar to switchboards, panels, and high- voltage outfit areas.

Key Points:

- IS 15652:2006 Insulating Mats for Electrical is an Indian Standard issued by the Bureau of Indian Standards( BIS).

- It applies to separating mats used for electrical safety in workplaces.

- The standard specifies conditions for material, consistency, and construction.

- It includes tests for dielectric strength, electrical resistance, and leakage current.

- Ensures protection of the labor force from electric shock near electrical installations.

Why is BIS Certification Mandatory

BIS certification Insulating Mats for Electrical is obligatory to ensure that separating mats used for electrical purposes misbehave with IS 15652:2006 safety norms. It protects workers from electric shock by assuring proper sequestration, electrical resistance, and continuity. The obligatory instrument also prevents the use of unacceptable products, ensures legal compliance in India, and builds trust by attesting that products are tested, approved, and constantly manufactured under BIS guidelines.

Key Reasons:

- Ensures separating mats meet IS 15652:2006 safety and quality conditions.

- Protects workers from electric shock in electrical installations.

- Prevents use of unacceptable or unsafe electrical safety products.

- obligatory for legal compliance to vend and use products in India.

- BIS mark confirms products are tested, approved, and dependable.

Importance and Benefits of BIS Certification

| Importance | Benefits |

| Ensures compliance with IS 15652:2006 electrical safety standards. | Enhances worker safety in front of electrical panels and switchgear. |

| Confirms separating mats give effective protection against electric shock. | Builds trust among buyers, inspectors, and nonsupervisory authorities. |

| Maintains harmonious product quality through regular BIS testing and surveillance. | Improves product continuity and long- term performance. |

| obligatory for manufacturers to fairly distribute separating mats in India. | Minimizes accidents, injuries, and liability for associations. |

| Reduces workplace electrical hazards and safety pitfalls. | BIS mark increases request acceptance and business credibility. |

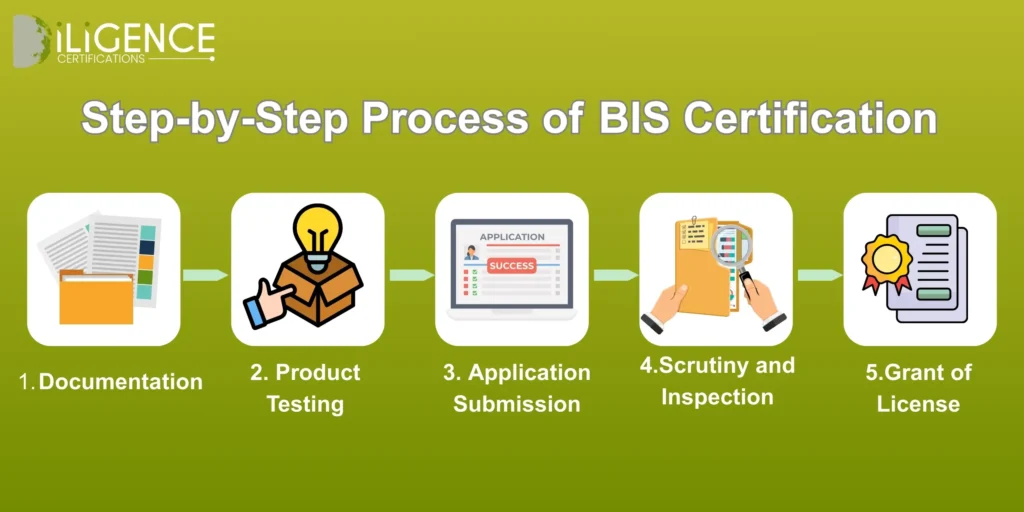

Step-by-Step Process of BIS Certification

Step1:Documentation

- Collect required technical documents

- Prepare product specifications

- Gather company registration details

- Ensure documents follow BIS format

Step2:Product Testing

- Send samples to a BIS-approved lab

- Conduct safety and quality tests

- Receive test reports

- Confirm compliance with BIS standards

Step3:Application Submission

- Fill out the BIS application form

- Upload all required documents

- Attach valid test reports

- Pay the necessary BIS fees

Step4:Scrutiny and Inspection

- BIS reviews submitted documents

- Authority verifies test results

- Factory/product inspection may occur

- Clarifications requested if needed

Step5:Grant of License

- BIS approves the application

- License number is issued

- Product can carry BIS mark

- Renewal required before expiry

Documents Required for BIS Certification

| Category | Documents Required |

| Business Documents | Business license/registration, ISO certificate, organizational details |

| Manufacturer Details | Factory layout, process flow chart, machinery list, production details |

| Product Documents | Product specifications, component list, user manual, model details |

| Testing Documents | Test report from BIS-recognized lab, sample details, test request form |

| Legal & Compliance | Authorization letter, brand ownership proof, trademark certificate (if any) |

| Import/Foreign Manufacturer (If applicable) | AIR (Authorized Indian Representative) details, contract agreement, overseas manufacturer documents |

Timelines, Costs, Validity & Renewal

- Timelines: Usually from 20 to 30 days, with only 7-15 days for the testing.

- Costs: The cost of the government and the test varies depending on the product. There can be some additional charges though.

- Validity: The validity period is 2 years in most situations.

- Renewal: The renewal is done before the expiration; there should be updated documents/tests; the renewal

Why Choose Diligence Certifications

Diligence Certifications offers expert guidance and end- to- end support for BIS instruments with a focus on delicacy, speed, and compliance. Our educated professionals simplify complex procedures, handle attestation, testing collaboration, and liaison with authorities, icing a smooth instrument process. With transparent communication, substantiated backing, and proven assiduity moxie, we help businesses achieve BIS blessing efficiently and confidently.

Conclusion

BIS Certification for Insulating Mats under IS 15652:2006 plays a vital part in icing electrical safety and nonsupervisory compliance in India. It guarantees that separating mats meet essential quality, performance, and safety norms, guarding workers from electrical hazards. Choosing a dependable instrument mate ensures a smooth blessing process, harmonious compliance, and long- term trust in product quality and safety.

Frequently Asked Questions (FAQs)

What's BIS certification for separating mats?

It's obligatory blessing icing separating mats meet IS 15652:2006 safety norms.

Is BIS certification mandatory for separating mats in India?

Yes, it's obligatory for manufacturing, selling, and using separating mats in India.

Which standard applies to electrical separating mats?

IS 15652:2006 issued by the Bureau of Indian standards (BIS).

Where are separating mats generally used?

In front of electrical panels, switchboards, and high- voltage outfit.

What tests are conducted under IS 15652:2006?

Dielectric strength, electrical resistance, and leakage current tests.

Who needs to apply for BIS Certification?

Manufacturers of separating mats, including domestic and foreign manufacturers.

How long does BIS Certification take?

generally 20 – 30 days, including product testing.

What's the validity of BIS Certification?

generally valid for 2 times.

Can foreign manufacturers apply for BIS Certification?

Yes, through a sanctioned Indian Representative (AIR).

Why is the BIS mark important?

It assures product safety, quality, compliance, and request acceptance.

BIS Certification

BIS Certification

CDSCO

CDSCO

CPCB

CPCB

LMPC

LMPC

WPC Approval

WPC Approval

Global Approvals

Global Approvals

TEC

TEC

ARAI

ARAI

BEE

BEE

ISO Certification

ISO Certification

Drone Registration

Drone Registration

NOC For Steel

NOC For Steel

Business Registration

Business Registration

Legal Services

Legal Services

Trademark Registration

Trademark Registration

Copyright Registration

Copyright Registration

Patent Registration

Patent Registration